A container system used in oil well drilling operations

A container technology during operation, which is applied in the field of ship engineering, can solve the problems of inconvenient transportation, large floor space, low efficiency, etc., and achieve the effects of reducing impact, ensuring lateral strength and rigidity, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

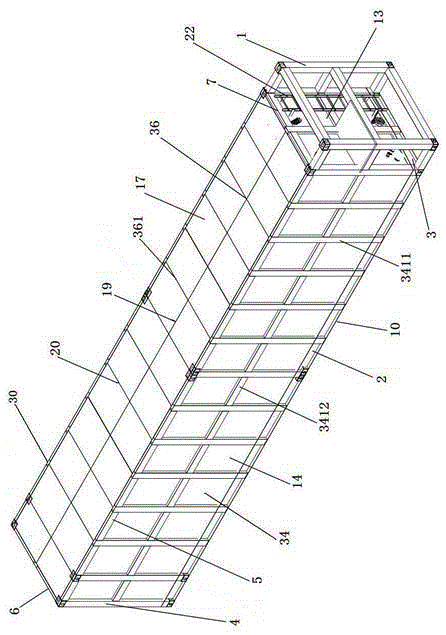

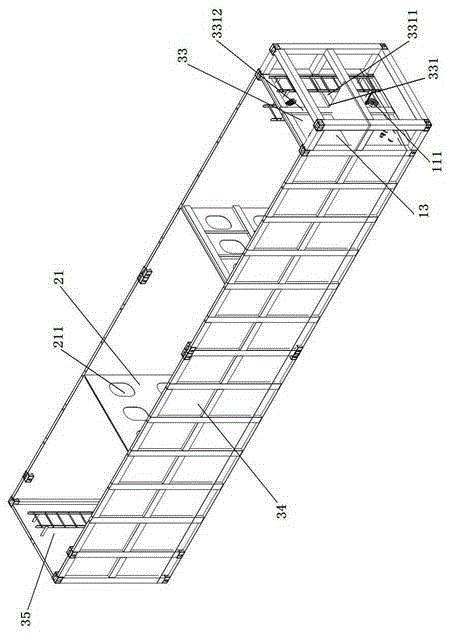

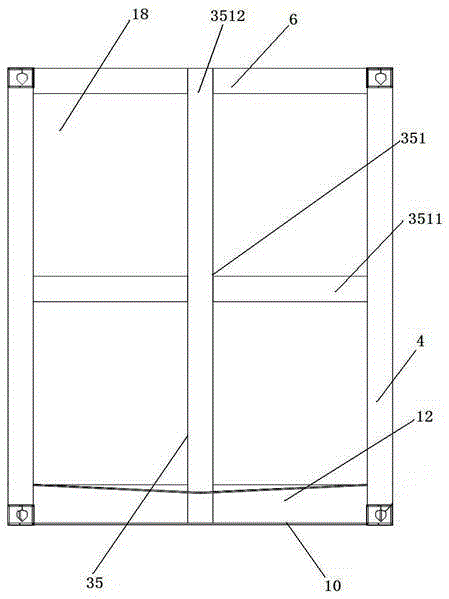

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] Such as figure 1 , figure 2 As shown, the present invention comprises outer frame 30, front frame 1, box bottom 32, front end wall 33, two side walls 34, rear end wall 35, box top 36, and outer frame 30 is cuboid structure, and box top 36 is outer frame 30 the top surface of the outer frame 30, the bottom of the box 32 is the bottom surface of the outer frame 30, the two side walls 34 are the two sides on the length direction of the outer frame 30, the front end wall 33 and the rear end wall 35 are respectively the two sides on the width direction of the outer frame 30 , the front frame 1 is arranged on the front end wall 33;

[0024] The outer frame 30 includes two bottom side beams 2, two bottom end beams 3, four corner columns 4, two top side beams 5, a rear end lintel 6, and an upper end beam 7; two bottom side beams 2, two bottom end beams The beams 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com