Intermittent stretching air-permeable material and process flow thereof

A technology of breathable materials and process flow, applied in the field of intermittent stretching breathable materials and its process flow, can solve the problems of low tensile strength and elongation rate, high energy consumption, film rupture, etc., and achieve transverse tensile strength and elongation Good elongation, good air permeability and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

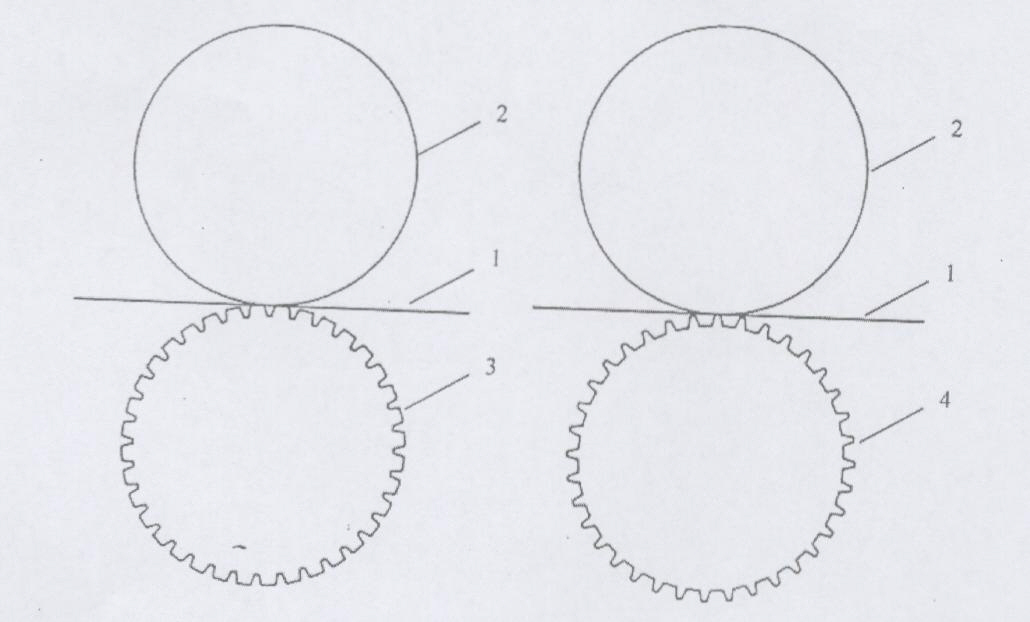

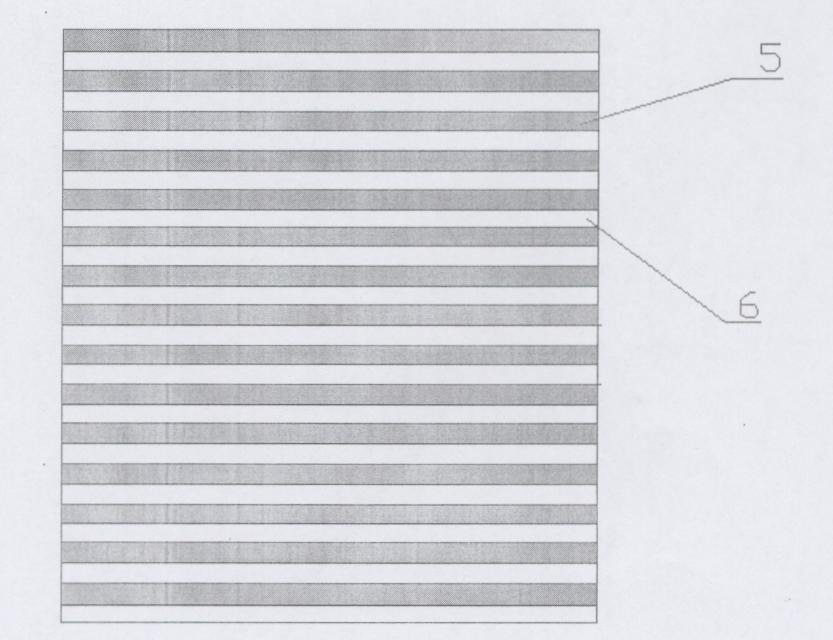

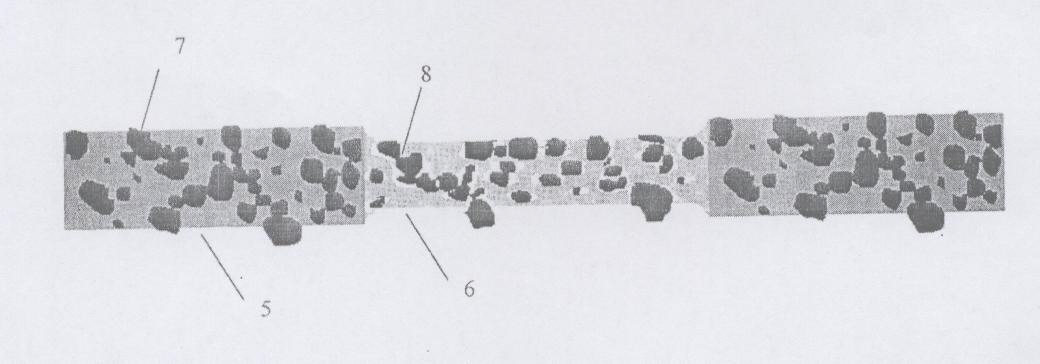

[0016] Such as figure 1 , 2 , a kind of intermittent stretching breathable material and its technological process shown in 3, the PE film 1 containing 40-60% calcium carbonate 7 that needs to be processed passes through the rigid roller 3 with grooves or the steel roller with convex lines 4. By applying pressure between the rubber roller 2 and the steel roller, the film is partially stretched along with the deformation of the rubber roller 2 to form light and dark interval stripes, and then cut and rolled for finished packaging. The local stretched width ranges from 0.1-1mm and appears white, while the unstretched part appears dark gray. The pressure range between the rubber roller and the steel roller is 0.5-10Mpa, and the contact time range is 0.1-10 seconds.

[0017] Due to the local stretching of the PE film 1 containing 40-60% calcium carbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com