Oxygen and nitrogen separation device with molecular sieve and hollow fiber membrane

A fiber membrane and molecular sieve technology, applied in the field of oxygen and nitrogen production, can solve the problems of large volume and weight, complex system piping, low nitrogen production efficiency, etc., to simplify the system structure, reduce volume and weight, and improve nitrogen production efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

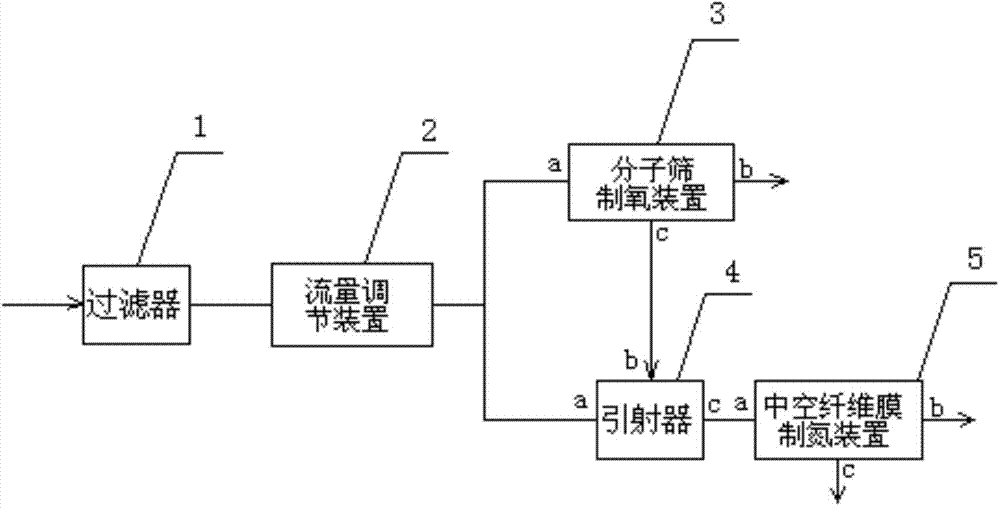

[0007] The present invention will be described in further detail below. see figure 1 , a molecular sieve and hollow fiber membrane oxygen and nitrogen separation device is characterized in that it consists of a filter 1, a flow regulator 2, a molecular sieve oxygen generator 3, an ejector 4 and a hollow fiber membrane nitrogen generator 5; the filter The air inlet of filter 1 is connected with the air source, the air outlet of filter 1 is connected with the air inlet of flow regulating device 2 through pipelines, and the air outlet of flow regulating device 2 is respectively connected with the air inlet of molecular sieve oxygen generator 3 through pipelines The port 3a communicates with the ejector gas inlet 4a of the ejector 4, and the low-concentration nitrogen-enriched gas outlet 3c of the molecular sieve oxygen generator 3 communicates with the ejected gas inlet 4b of the ejector 4 through a pipeline, and the molecular sieve The oxygen gas outlet 3b of the oxygen generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com