Transformer oil and preparation method thereof

A transformer oil and transformer technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as not being able to meet the increasing and increasing requirements of safety and standards, and achieve the effects of improving breakdown performance, improving thermal conductivity, and improving insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

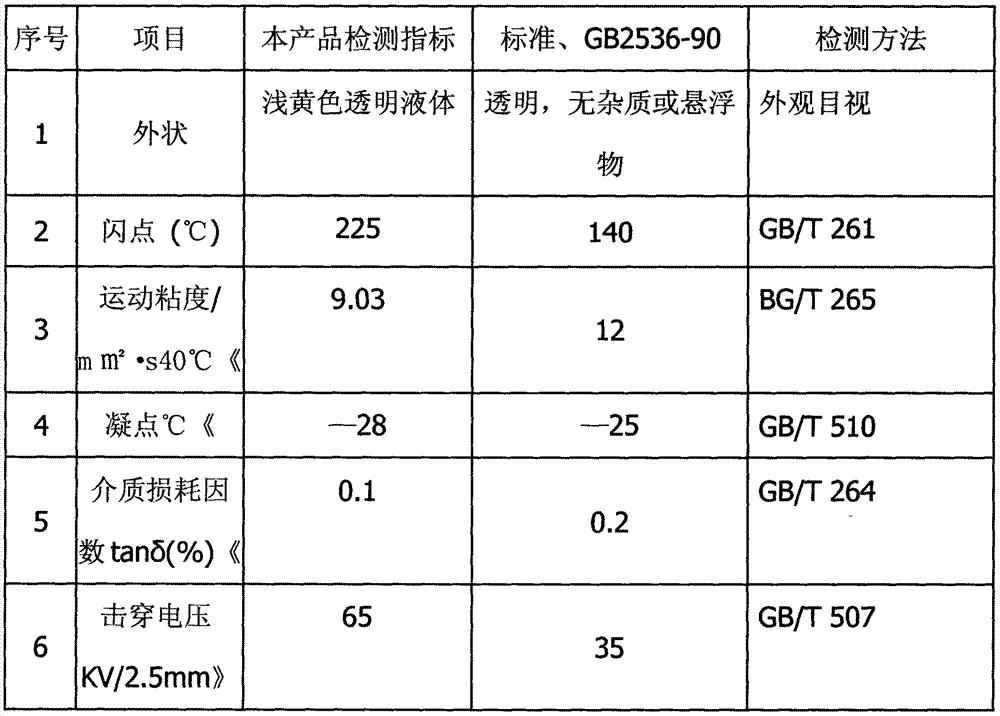

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

[0018] A transformer oil consisting of the following components by weight:

[0019] Antioxidant 0.05%

[0020] Surfactant 0.03%

[0021] BN nanoparticles 0.03%

[0022] The balance is transformer base oil.

[0023] Further, the transformer base oil is paraffin-based or naphthenic mineral oil.

[0024] Preparation method of transformer oil:

[0025] 1) Put BN nanoparticles and surfactant into an organic solvent and fully mix and stir;

[0026] 2) Add the product in step 1) into the transformer base oil, fully stir in a water bath at 40°C until the organic solvent is completely volatilized, then ultrasonically oscillate for 1 hour, and stand to obtain stable larvae with evenly dispersed BN nanoparticles;

[0027] 3) drying to remove water;

[0028] 4) Add white clay, adsorb at 120°C to 135°C for 2.5 hours at high temperature, and then finely filter;

[0029] 5) adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com