Vibration generating set and road speed bump with same

A technology of vibration power generation and speed bumps, which is applied in the direction of mechanical power generating mechanisms, roads, roads, etc., can solve the problems of large power supply line laying engineering, high construction and use costs, and non-concentrated load distribution, etc., to achieve electromechanical energy conversion High efficiency, reduced energy waste and use costs, and large output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

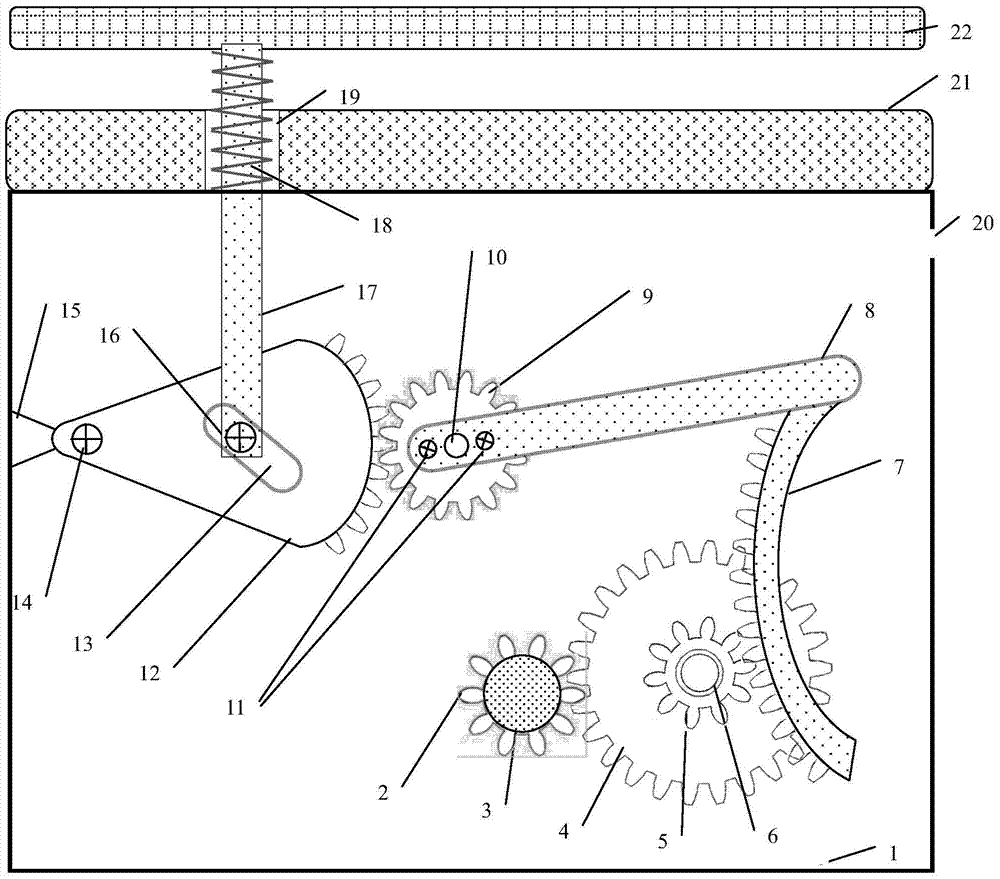

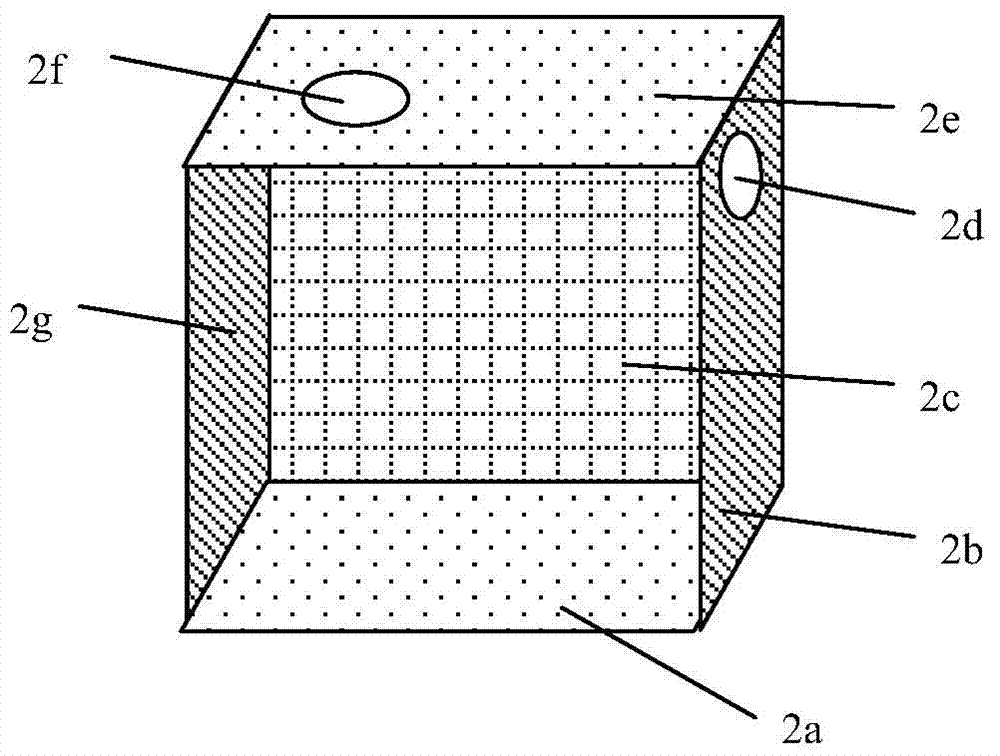

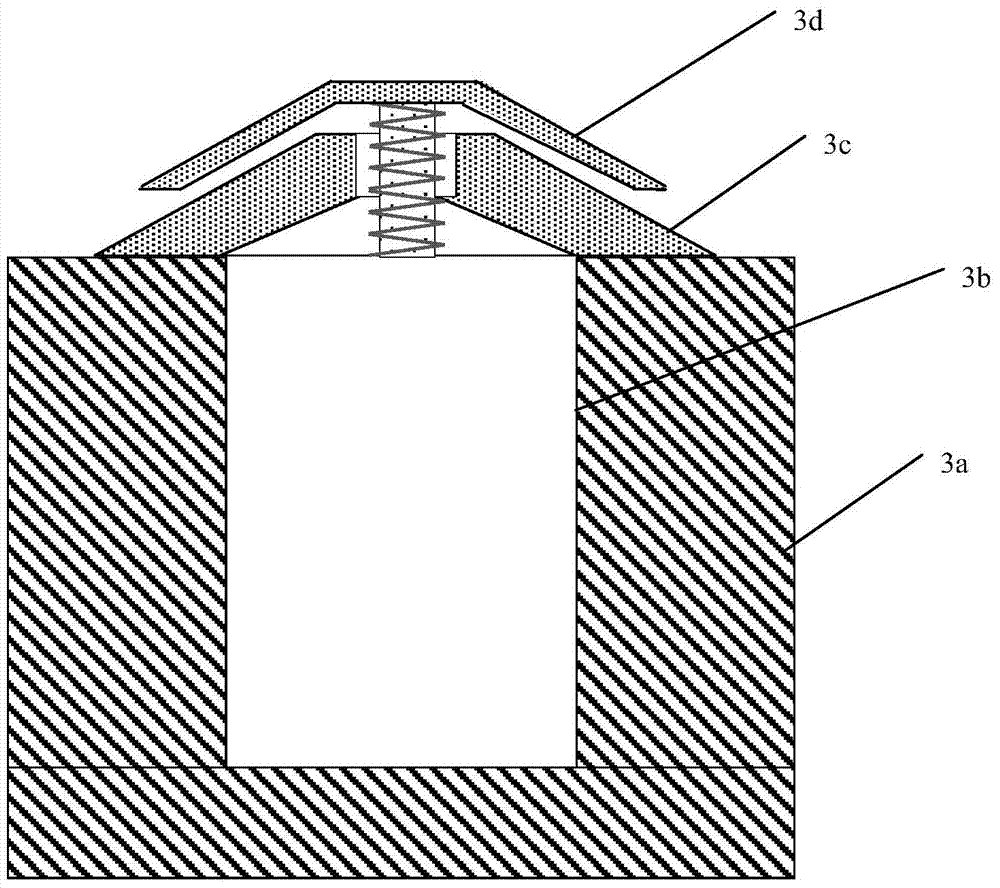

[0029] The structural diagram of the vibration power generation device according to the present invention is as follows: figure 1 As shown, the device is a box structure with a cuboid shape; inside the box, shaft two 10, shaft three 6 and permanent magnet synchronous generator 3 are all fixed on the main inner wall of the box by screws, and the bearing seat 15 is fixed on the box On the inner wall on the left side of the main inner wall, the shaft one 14 is fixed on the bearing seat 15; the one-way bearing is fixed on the shaft of the permanent magnet synchronous generator 3 through key fit, and the gear three 2 is fixed on the one-way bearing through key fit; Gear 2 4 and gear 1 5 are both fitted on shaft 3 6 through keys, gear 1 5 drives gear 2 4 to rotate synchronously, gear 2 4 is close to the inner wall; gear 3 2 meshes with gear 2 4; rack 7 is along the vertical direction Placement, the upper end of the rack 7 and the right end of the swing rod 8 are fixed together by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com