A precision integrated magnetic suspension bearing

A magnetic suspension bearing, a precise technology, applied in the field of bearings, can solve the problems of difficult precision machining, limited rotation accuracy, difficulty in machining ring grooves, etc., to achieve the effects of easy processing and installation, improved rotation accuracy, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, and the present invention is not limited to the following examples;

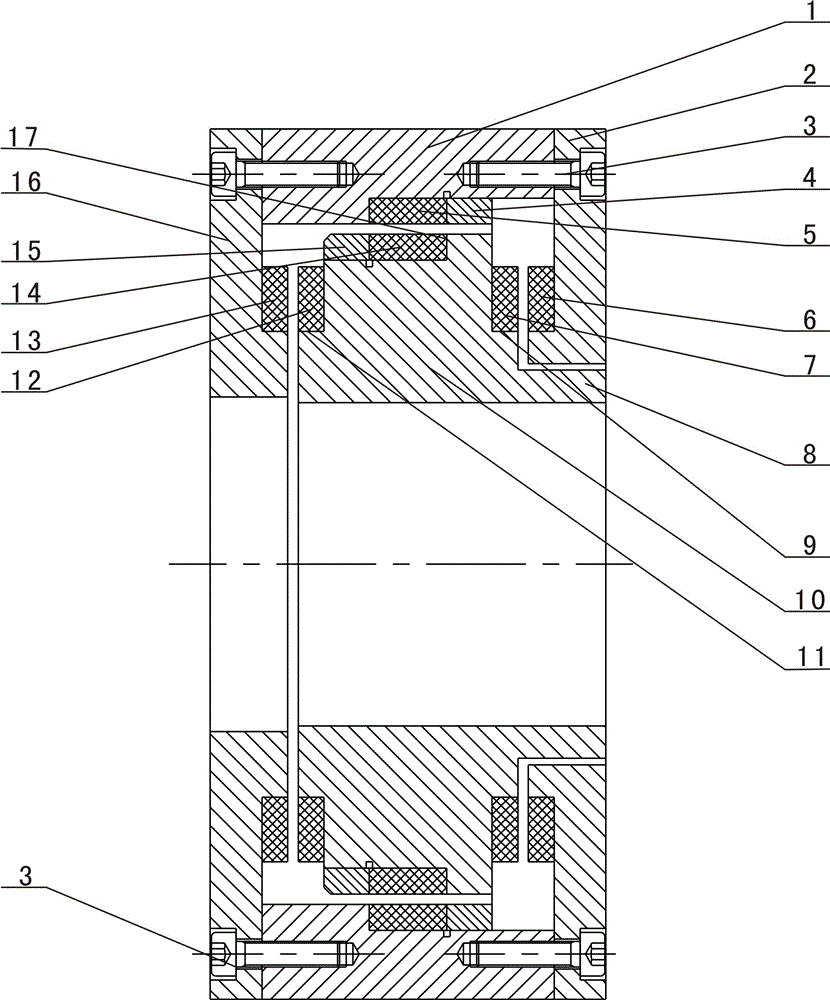

[0024] combined with figure 1 The precision integrated magnetic suspension bearing includes an outer ring 1, an inner ring 10, a ring seat A2, a ring seat B16 and a screw 3, and an outer ring 1 which is rotatably matched with the inner ring 10 is arranged on the outside of the inner ring 10. One end of the ring 10 is provided with a first step 8 and a second step 9, and the other end of the inner ring 10 is provided with a third step 11 and a fourth step 17, the diameter of the second step is greater than the diameter of the first step, The first step 8 is set in the shaft hole of the ring seat A2, and the axial magnetic ring B7 is arranged on the step surface of the second step. The diameter of the fourth step 17 is larger than the diameter of the third step 11. The step surface of the three steps 11 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com