Inter-tube-bundle high-temperature high-pressure vapor-liquid two-phase flow pattern experimental device and flow pattern identification method

A high-temperature, high-pressure, experimental device technology, applied to measuring devices, fluid dynamics tests, instruments, etc., can solve problems that do not involve boiling, heat transfer, vapor-liquid two-phase flow between high-pressure tube bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

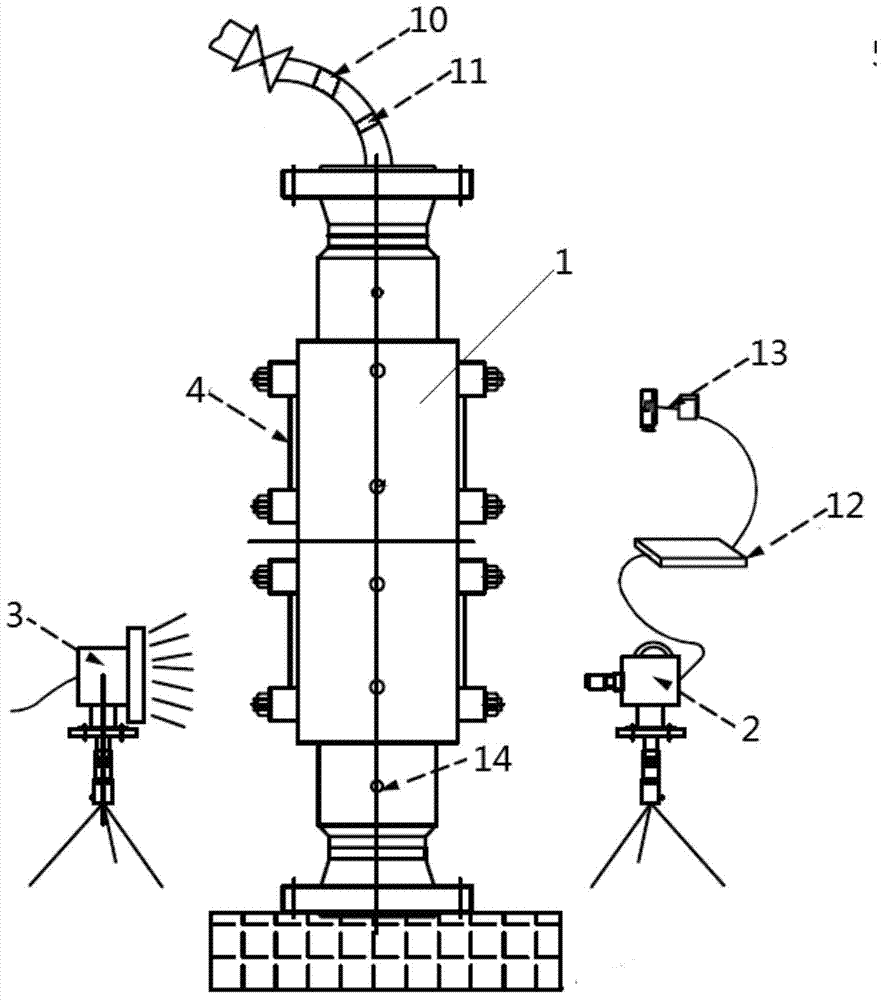

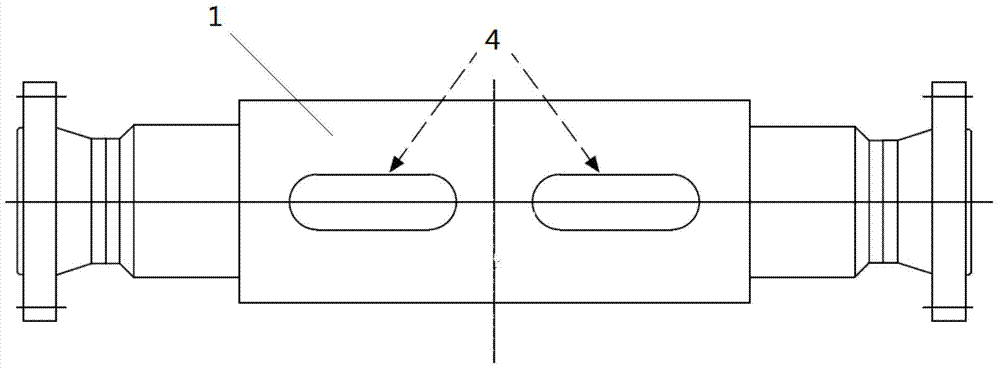

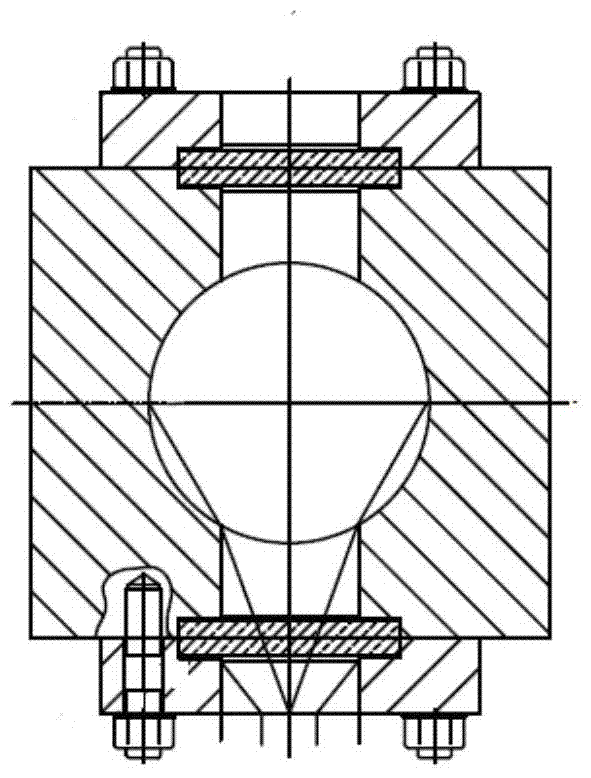

[0029] Such as figure 1 , figure 2 As shown, there are upper and lower two visualization windows 4 symmetrically opened on the front and rear sides of the pressure vessel 1, as shown in image 3 As shown, the cross section of the window is square on the outside and circular on the inside, and the window is provided with window glass. When implemented, the window is 398mm high, 100mm wide, and the upper and lower window spacing is 368mm. Such as figure 1 As shown, the laser generator 3 is located on the rear side of the pressure vessel 1, corresponding to the position of the visualization window on the rear side of the pressure vessel, and the high-speed camera 2 is located on the front side of the pressure vessel 1, corresponding to the position of the visualization window on the front side of the pressure vessel. The laser generator and high-speed camera are installed on the bracket, and the laser generator and high-speed camera can move up and down. Such as Figure 4 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com