Performance detection method and device of spray device

A technology of injection device and detection method, which is applied in the direction of measuring device, mechanical component test, machine/structural component test, etc., can solve problems such as high implementation cost, influence on coal powder diffusion, and inability to reflect the real performance of injection device, and achieve Easy operation and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

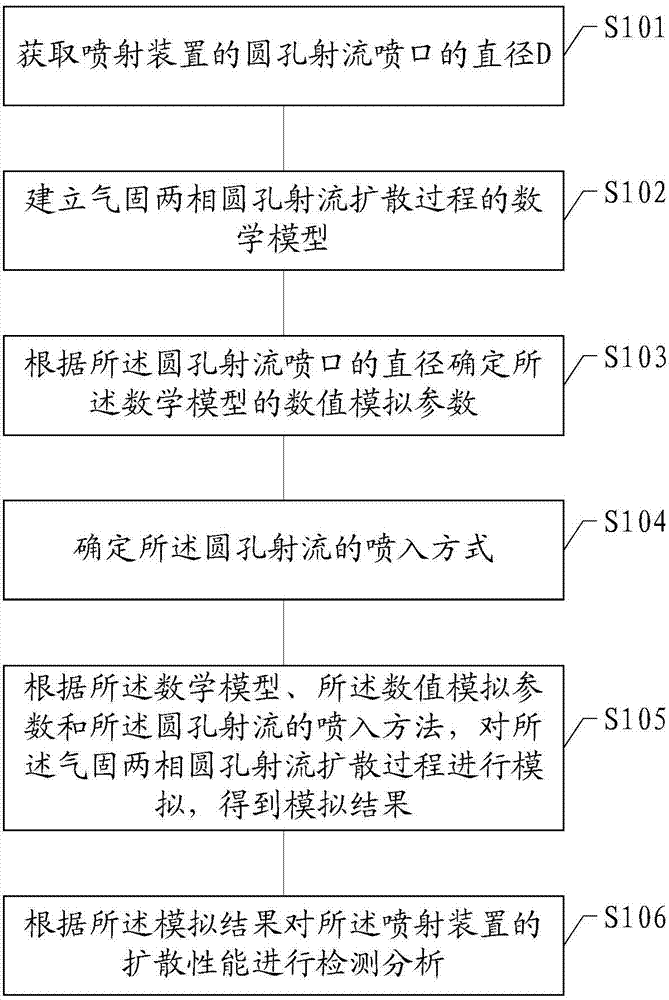

[0035] The embodiment of the present invention provides a method for testing the performance of an injection device, see figure 1 , the specific process of the method is as follows:

[0036] S101. Obtain the diameter D of the round hole jet nozzle of the injection device.

[0037] Under the extrusion of the injection device, the pulverized coal passes through the nozzle to form a circular hole jet and enters the boiler combustion chamber.

[0038] S102, establishing a mathematical model of a gas-solid two-phase circular hole jet diffusion process.

[0039] The mathematical model is a reasonable simplification and abstraction of the gas-solid two-phase circular hole jet diffusion process, enabling the original complex diffusion process to be simulated by a computer.

[0040] In the mathematical model, the gas can be considered as an ideal Newtonian fluid, the pulverized coal particles are rigid spheres with the same diameter and density, the ratio of the particle density to t...

Embodiment 2

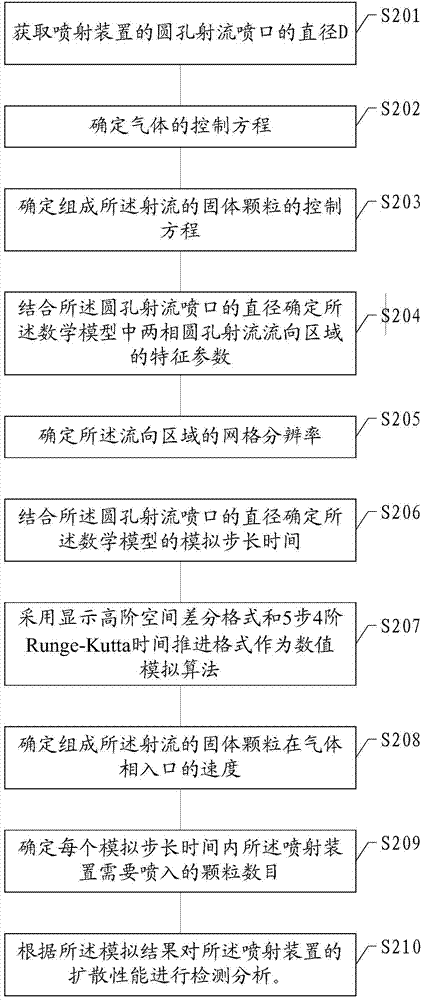

[0050] The embodiment of the present invention provides a method for testing the performance of an injection device, see figure 2 , the specific process of the method is as follows:

[0051] S201. Obtain the diameter D of the round hole jet nozzle of the injection device.

[0052] S202, determining the governing equation of the gas.

[0053] The governing equations of gas include: continuity equation, momentum equation, temperature equation, and state equation.

[0054] in particular:

[0055] The continuity equation is ∂ ρ ∂ t + ∂ ρ u i ∂ x i = 0 ,

[0056] The momentum equation is ∂ ρ u ...

Embodiment 3

[0118] An embodiment of the present invention provides a performance detection device for an injection device, see Figure 9 , the device specifically includes:

[0119] The acquisition module 301 is configured to acquire the diameter D of the round hole jet nozzle of the injection device.

[0120] The modeling module 302 is used to establish a mathematical model of the gas-solid two-phase circular hole jet diffusion process.

[0121] Specifically, the modeling module 302 is specifically used for:

[0122] determine the governing equations for the gas;

[0123] determining equations governing the solid particles making up said jet;

[0124] Wherein, the governing equation of the gas includes: continuity equation, momentum equation, temperature equation, temperature equation finishing form, state equation,

[0125] The continuity equation is ∂ ρ ∂ t + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com