Diesel engine test method

A test method and diesel engine technology, applied in the field of diesel engine testing, can solve the problems of long test cycle, many harmful emissions from diesel engines, and long test time, and achieve the effects of optimizing the test sequence, optimizing the grinding sequence, and reducing the test cost.

Active Publication Date: 2014-04-02

DEUTZ DALIAN ENGINE

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]1. Serious energy waste, mainly including fuel and electricity consumption

[0006]2. There are many harmful emissions from diesel engines, mainly including nitrogen oxides, carbon monoxide, hydrocarbons, particles

[0007]3. There is no unified standard for test methods

[0008]4. The test cycle is too long to meet the production demand

[0014] (2) Diesel engine has many test steps and long test time;

Due to the many steps in the diesel engine test and the long test time, the energy waste is serious

[0018] (3) There is no verification method in the diesel engine test process, resulting in insufficient power of the whole vehicle;

[0022] (4) There is no database established for the diesel engine governor, and there is no unified standard for the position o

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

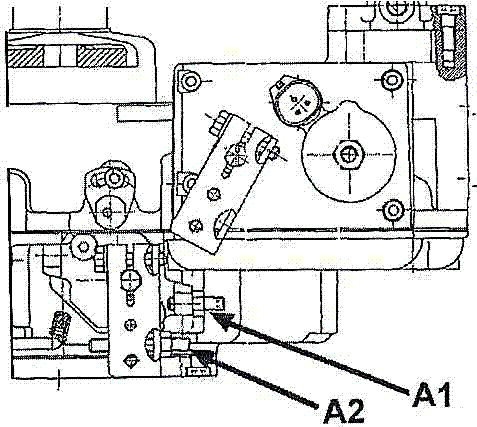

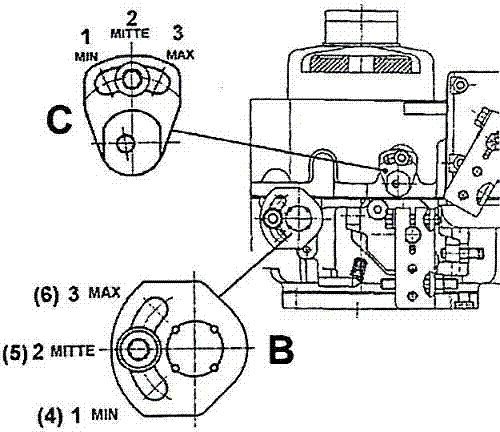

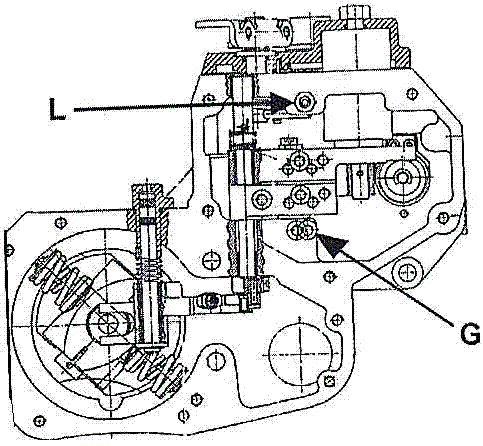

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

A diesel engine test method comprises the following steps: (A) program-controlled running-in of the diesel engine; (B) program-controlled test of the diesel engine. The running-in sequence of the diesel engine is optimized to avoid operation stop of the diesel engine in the test process; the test sequence and the test time of the diesel engine are optimized to reduce the test cost and improve the work efficiency. The diesel engine is pre-adjusted in the test process to reduce the test steps; the diesel engine performance is pre-adjusted in the program-controlled running-in stage and the program-controlled test stage of the diesel engine to save energy, reduce emission and improve productivity. A diesel engine test process verification means is established to simulate the running state of a whole vehicle to solve the problem of poor power performance of the whole vehicle, and can realize 100% timely verification of the test quality of Deutz diesel engines while lowering the maintenance cost. A diesel engine speed controller database is established to unify the position of diesel speed controller function limit screws; the speed controller is simplified from a complex trail state to a standardized table lookup, thereby solving the technical difficulty in adjusting the diesel engine performance.

Description

technical field [0001] The invention relates to the technical field of diesel engines, in particular to a test method for diesel engines. Background technique [0002] The process of running-in test with the power generated by the diesel engine itself is usually called hot test. It is to check whether the diesel engine has reached the proper assembly performance, and at the same time, it is used for the engine to run and close before the car runs, so as to ensure the normal use of the engine. Large diesel engines have high requirements on parameters and performance. Hot test has become the last key process in the production process, which plays a very important role in the quality of diesel engine manufacturing. The main content is to record and Analyze and judge whether it is qualified or not, and can detect and eliminate faults in time. [0003] At present, the gradually warming global climate and the increasingly depleted oil resources are directly related to the emissi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M15/04

Inventor 鹿新弟

Owner DEUTZ DALIAN ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com