Pipeline type LCD (Liquid Crystal Display) mounting equipment

An assembly equipment, assembly line technology, applied in nonlinear optics, transportation and packaging, optics, etc., can solve problems such as reducing work efficiency, affecting product quality, increasing production costs, etc., to achieve fully automated production, reduce labor, improve The effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

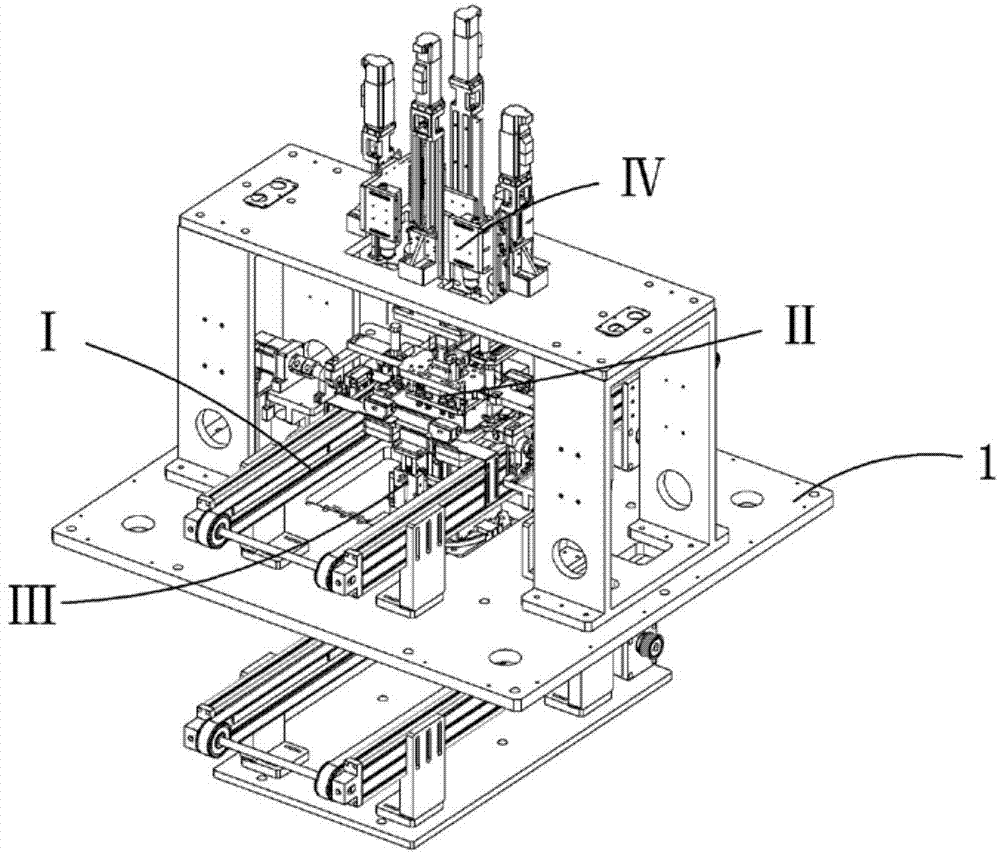

[0040] Examples, see attached figure 1 , a line-type LCD assembly equipment, which includes a base plate 1, a double-layer assembly line mechanism I, an overturning mechanism II, a jacking correction mechanism III, an alignment pressing mechanism IV, and a carrier 2, and the double-layer assembly line mechanism includes an upper assembly line mechanism and the lower assembly line mechanism, the jacking correction mechanism is installed on the lower assembly line mechanism; the upper assembly line mechanism is installed on the bottom plate; There is a square slot; and the overturning mechanism and the alignment pressing mechanism are located above the square slot.

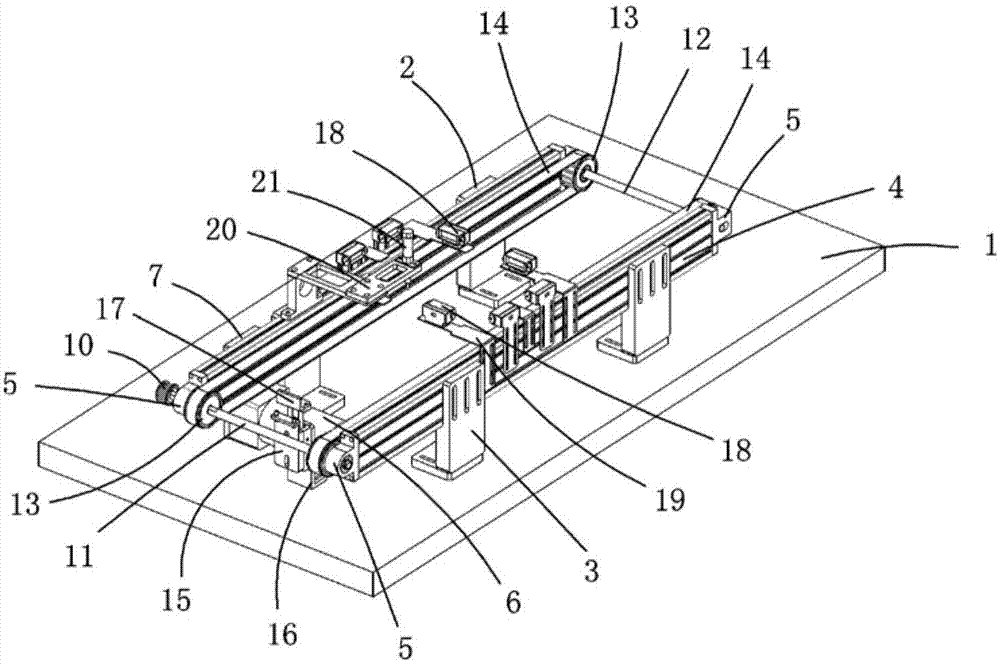

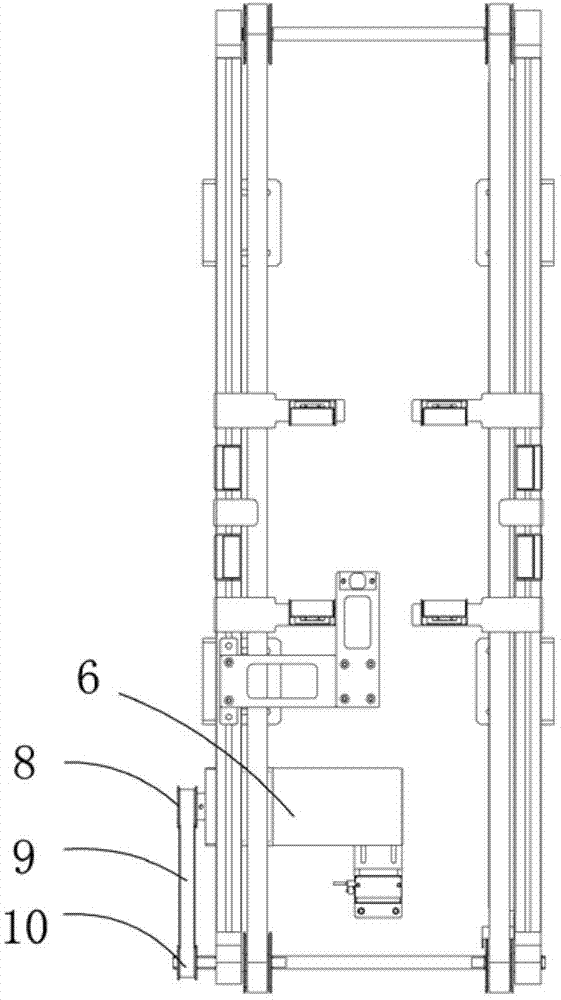

[0041] See attached figure 2 and 3 , the upper assembly line mechanism includes a left support block 2, a right support block 3, a pulley mounting plate 4, a transmission wheel fixing block 5, a driving motor 6, a motor fixing plate 7, a driving wheel 8, a pulley 9, a driven wheel 10, and a connecting shaft 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com