Low-voltage switch cabinet body

A technology for low-voltage switch cabinets and cabinets, which is applied in the directions of busbar/line layout, substation/power distribution device shell, etc., which can solve the problems of difficult processing of column thread holes and easy damage of columns, and achieve easier alignment and production The effect of short time and variable production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

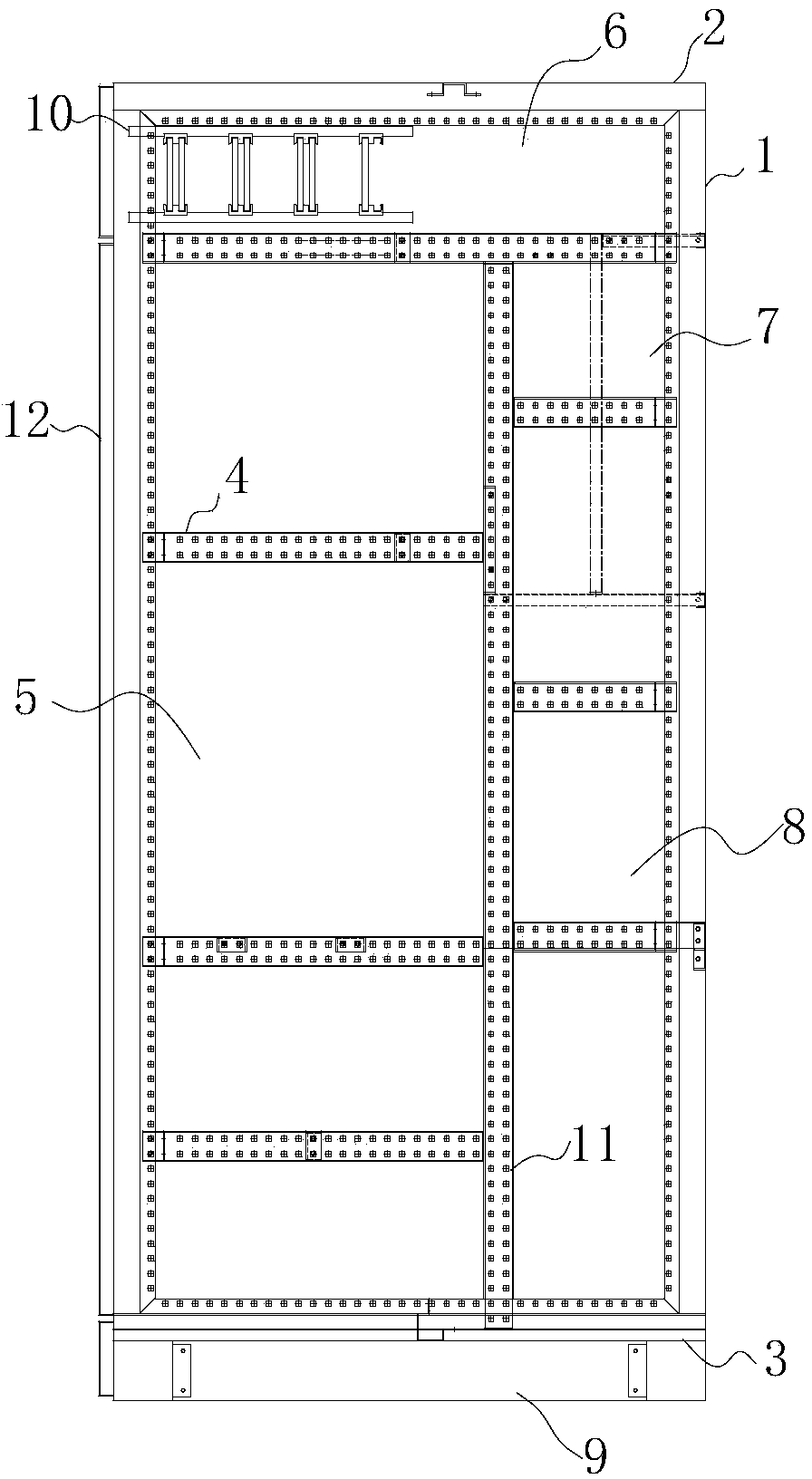

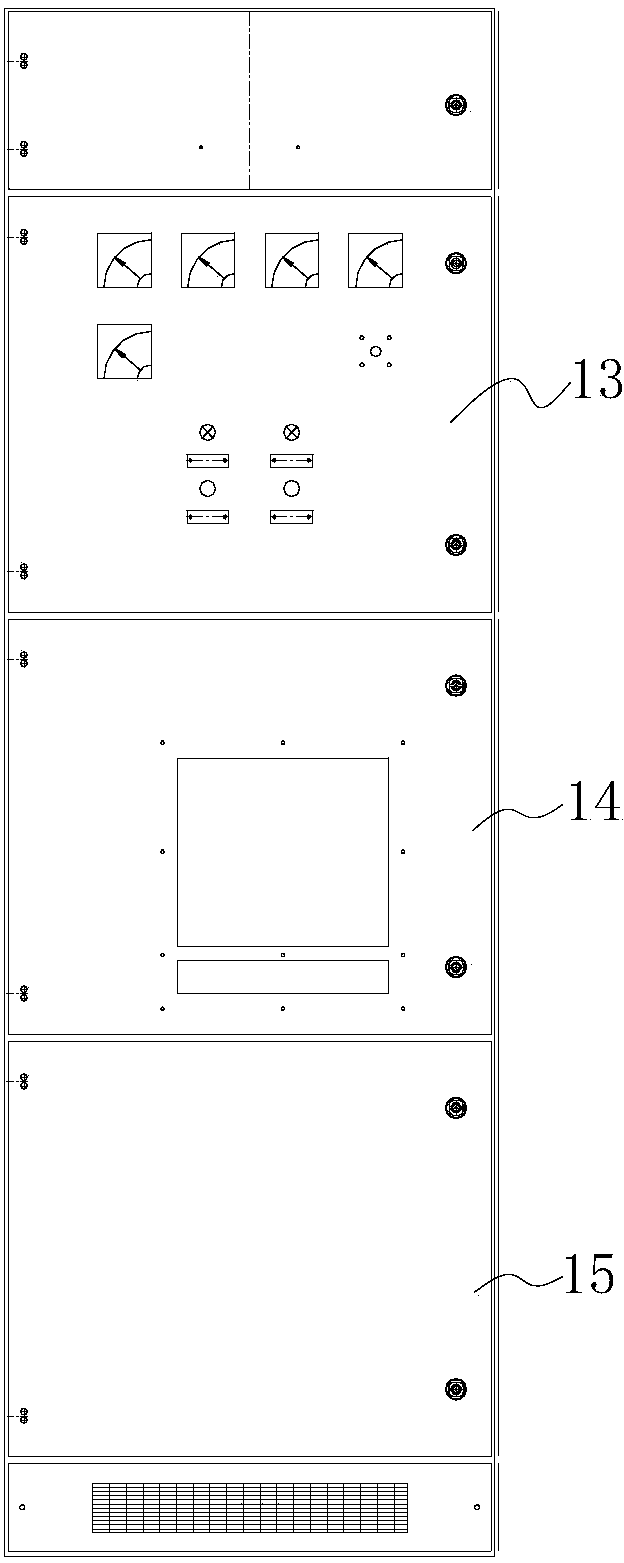

[0032] Such as figure 1 , 2 As shown, the low-voltage switchgear cabinet body of the present invention includes a frame, three side panels 12, a door panel and a cabinet top panel, and the frame includes a column 1, an upper beam 2 and a lower beam 3 arranged at the upper and lower ends of the column 1, connected with the column 1 and The middle beam 4 arranged horizontally and the supporting beam 11 arranged vertically between the two columns 1, three side panels 12, the cabinet top panel and the door panel enclose the inner space of the cabinet body, and the inner space of the cabinet body has a busbar room 6, instrument Room 7, cable room 5 and circuit breaker room 8, a plurality of square modulus holes that can be clamped with floating nuts are arranged on the column 1 along the height directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com