Motor driven equipment

A technology of motor drive and equipment, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of platform controller complexity and cost rise, and achieve the effects of decoupling, drive capacity growth, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

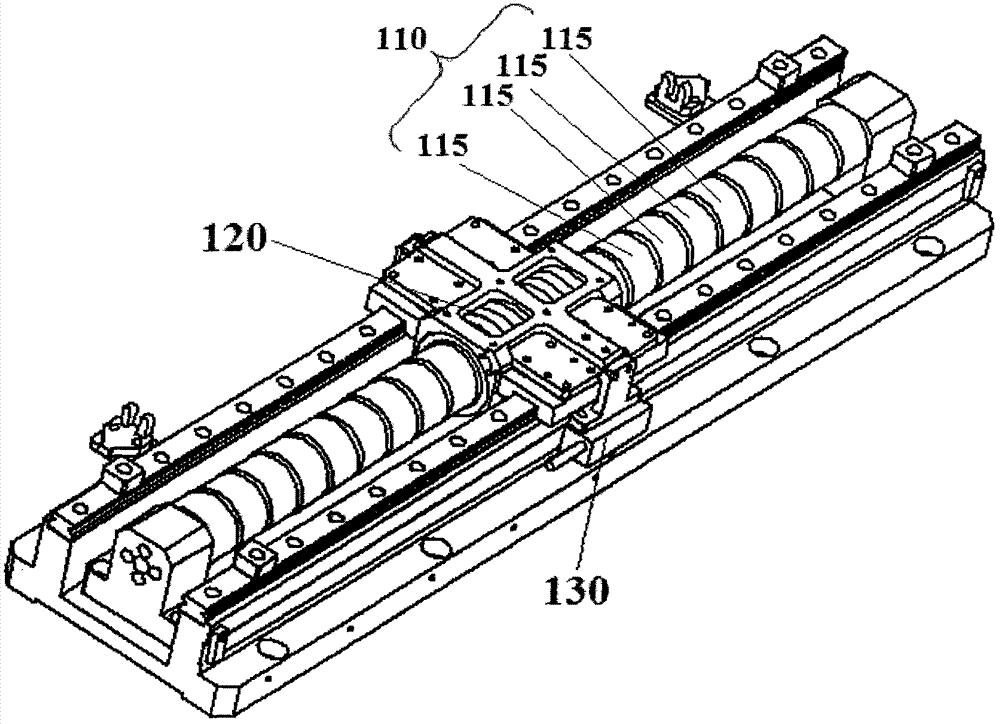

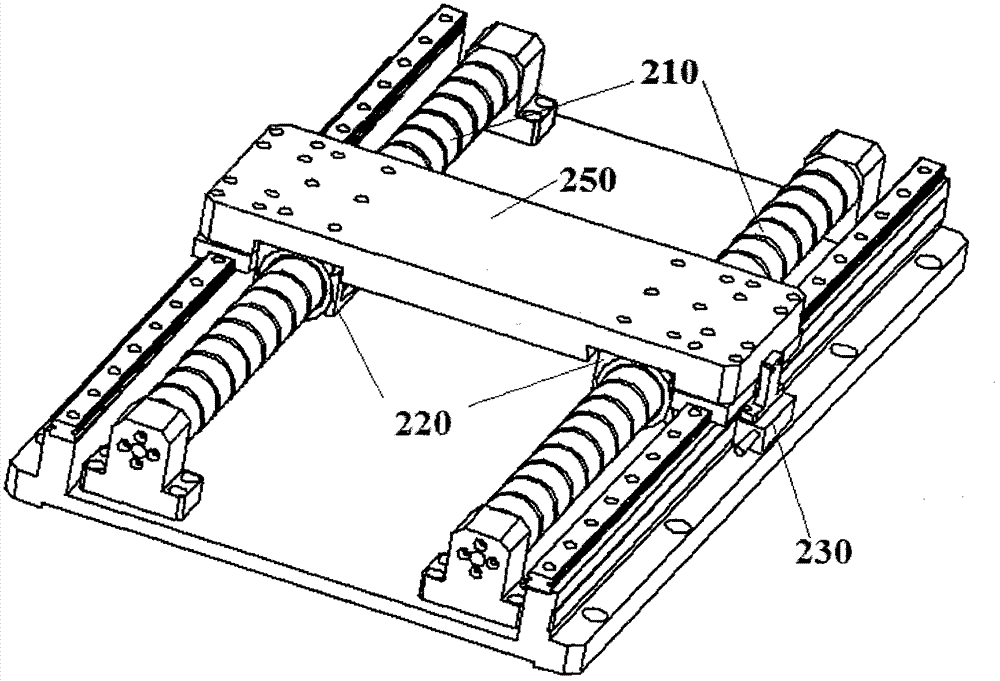

[0047] Refer to the attached figure 2 , 4 , 5. Describe in detail the embodiment of the motor-driven device according to the present invention.

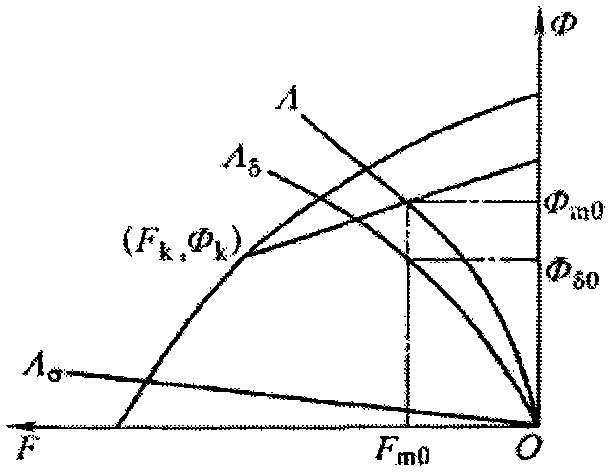

[0048] The multi-motor working platform proposed by the present invention can be compared with figure 2 are basically the same, but in motor design, the present invention adopts the design method of saturated magnetic field, specifically, the operating point of the motor is selected in the saturation region of the permanent magnet, such as Figure 5 Point B shown.

[0049] Since the motor works in the saturation region, even if there is a relatively large change and deviation in the operating point, it will not have a significant impact on the performance of the motor, so that it can well solve the interference of motor assembly, installation errors, work, and environmental temperature changes. Factors affect the performance of each motor. When multiple motors working at the same time are connected in series, their working perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com