A method for improving the heat transfer of the heat exchanger of the automobile box-type thermoelectric system

A technology of heat exchangers and thermoelectric systems, applied in current collectors, electric vehicles, electrical components, etc., can solve problems such as no increase in output power and rise in temperature at the hot end of heat exchangers, so as to increase output power and avoid overheating , the effect of saving automobile fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

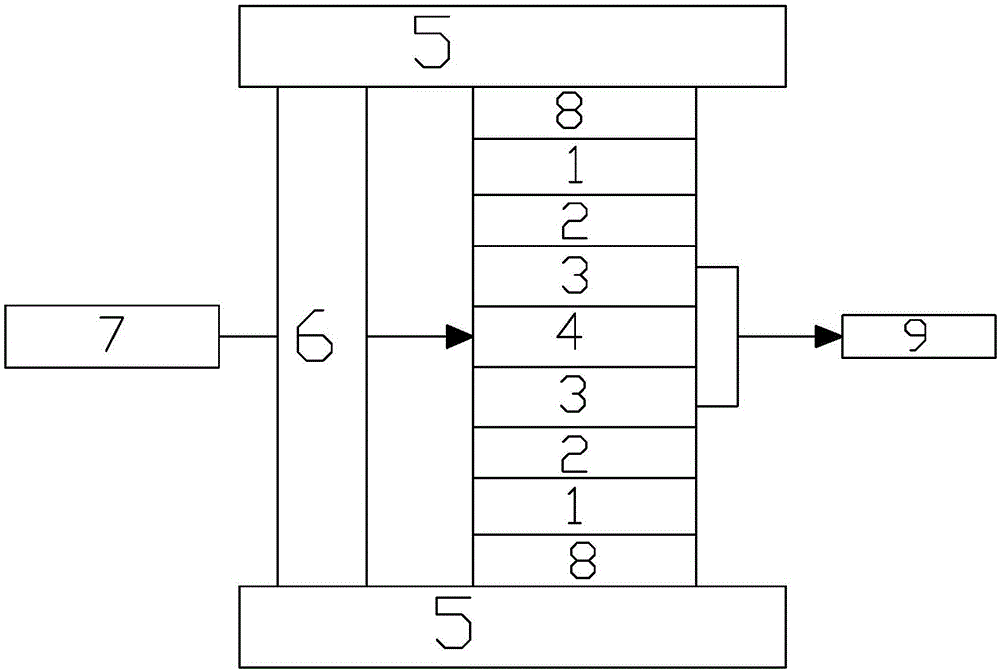

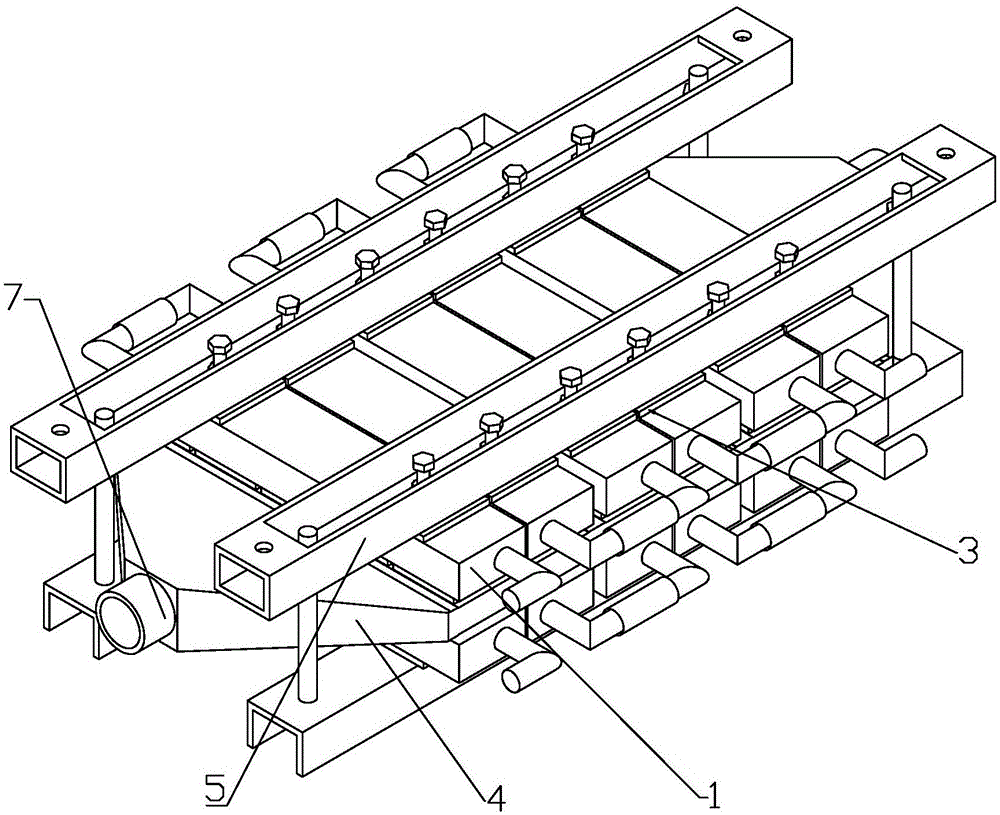

[0025] Attached below Figure 1-3 The principles and specific implementation methods of the present invention are further described.

[0026] Figure 1-3 As shown, the exhaust air temperature difference power generation heat exchanger of the present invention is suitable for the setting of the automobile box-type thermoelectric system, and the connection with the automobile-related devices is as follows: Figure 1-2 As shown, the automobile engine exhaust pipe 7 is communicated with the air inlet of the heat exchanger, and the tailpipe of the automobile rear exhaust pipe is communicated with the air outlet of the heat exchanger; the heat exchanger 4 is connected with the automobile battery 9; The π-shaped steel 5 compresses the entire heat exchanger system from top to bottom, and a support plate 6 is set between the upper and lower π-shaped steel 5 .

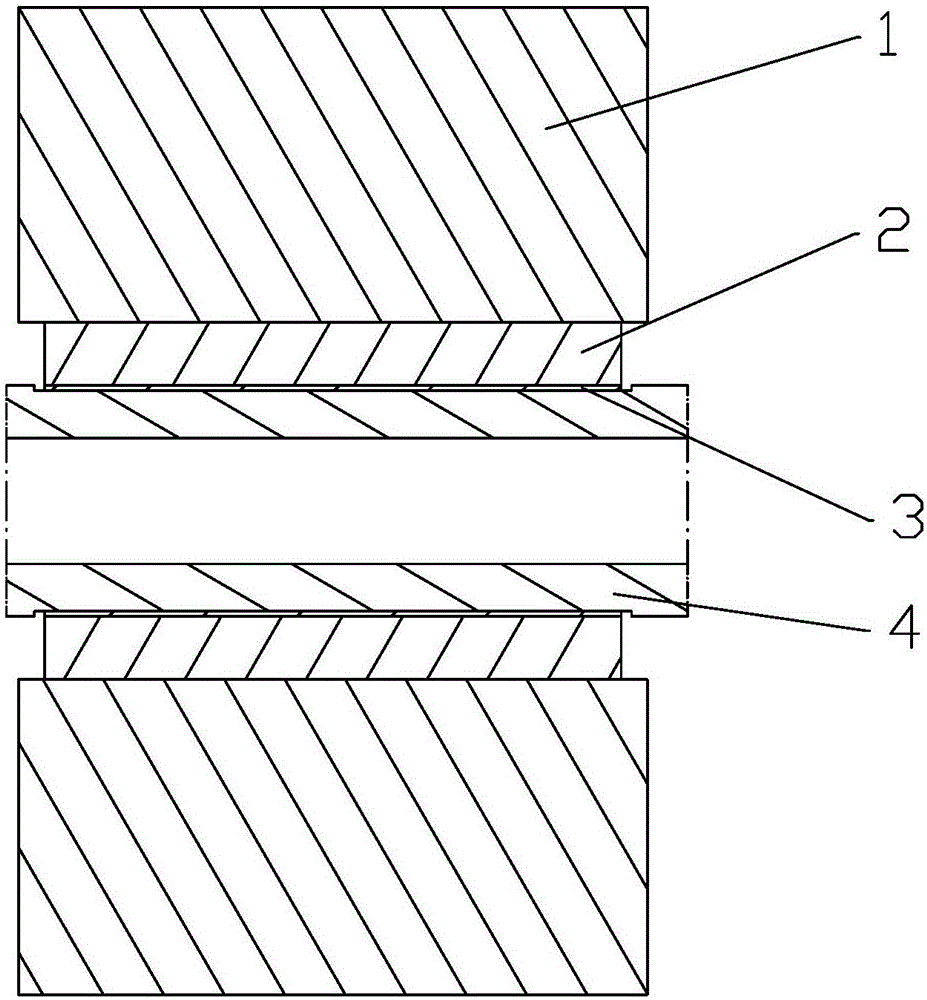

[0027] Figure 1-3 Among them, a layer of quartz cloth 3 with a certain thickness is placed between the heat exchanger 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com