Rear left-side type ditcher

A ditching machine and frame technology, applied in the direction of digging/covering ditches, agricultural machinery, agricultural machinery and implements, etc., can solve the problems of increased energy consumption, easy to cause injuries, easy entry of soil, etc., and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

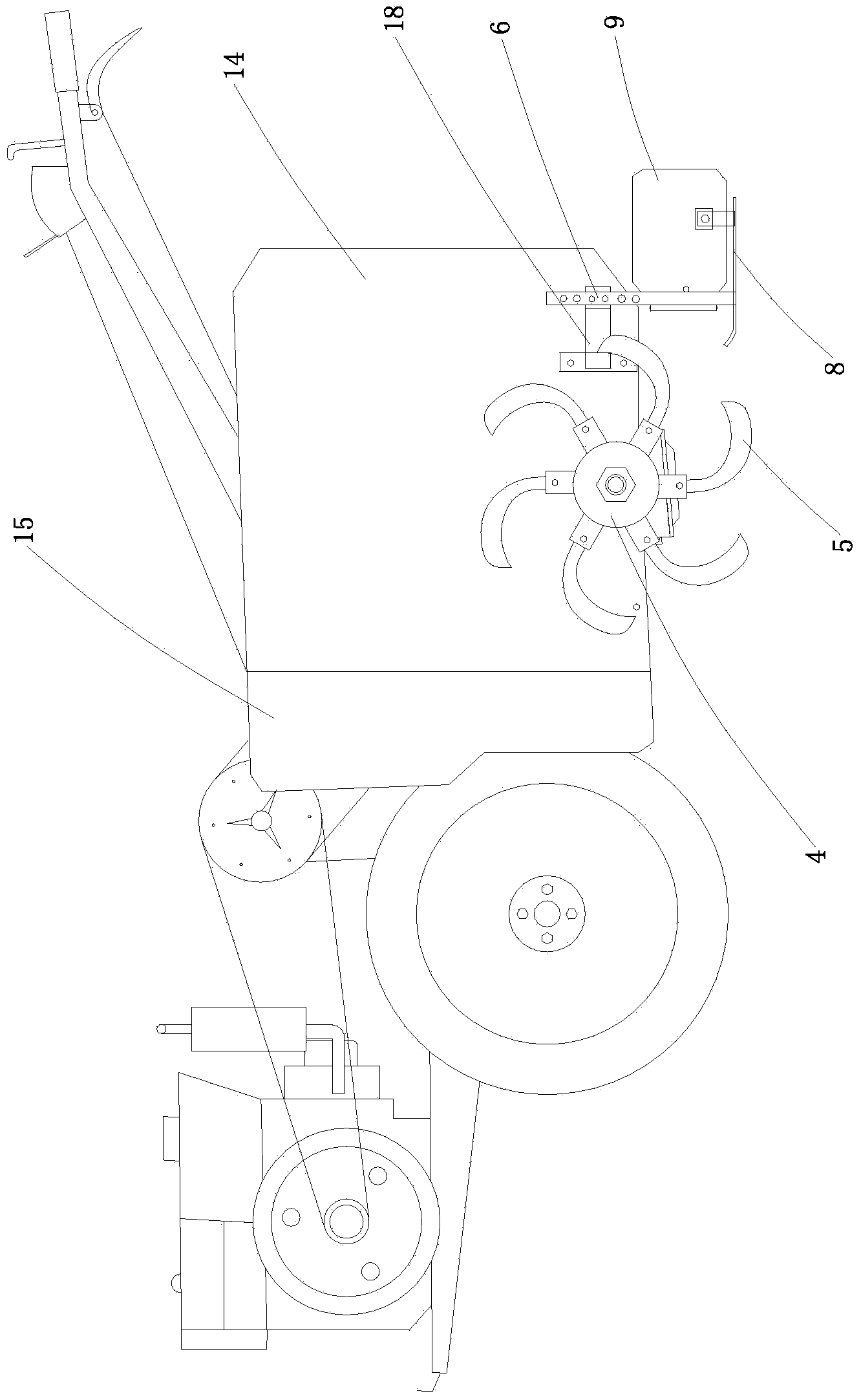

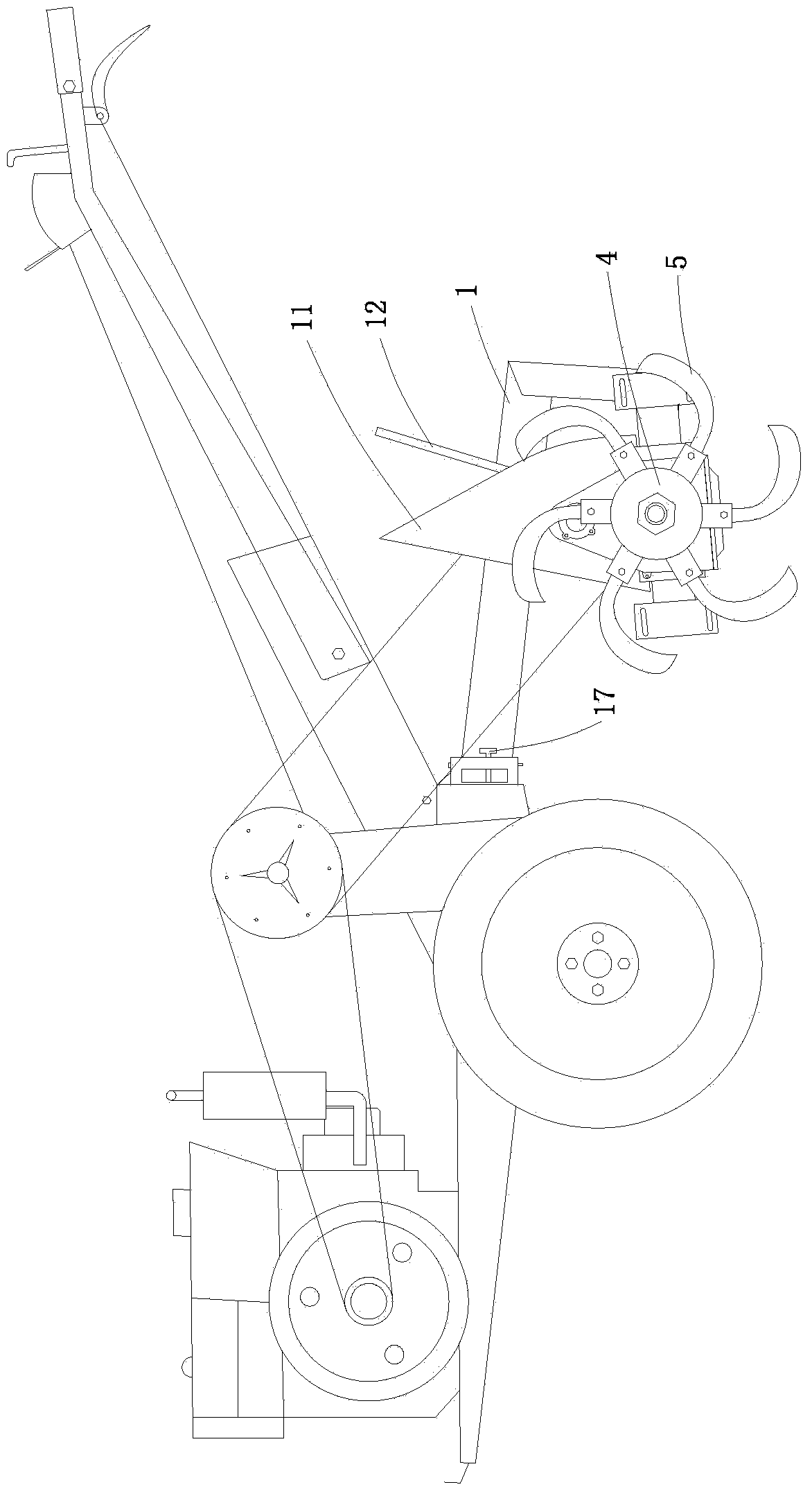

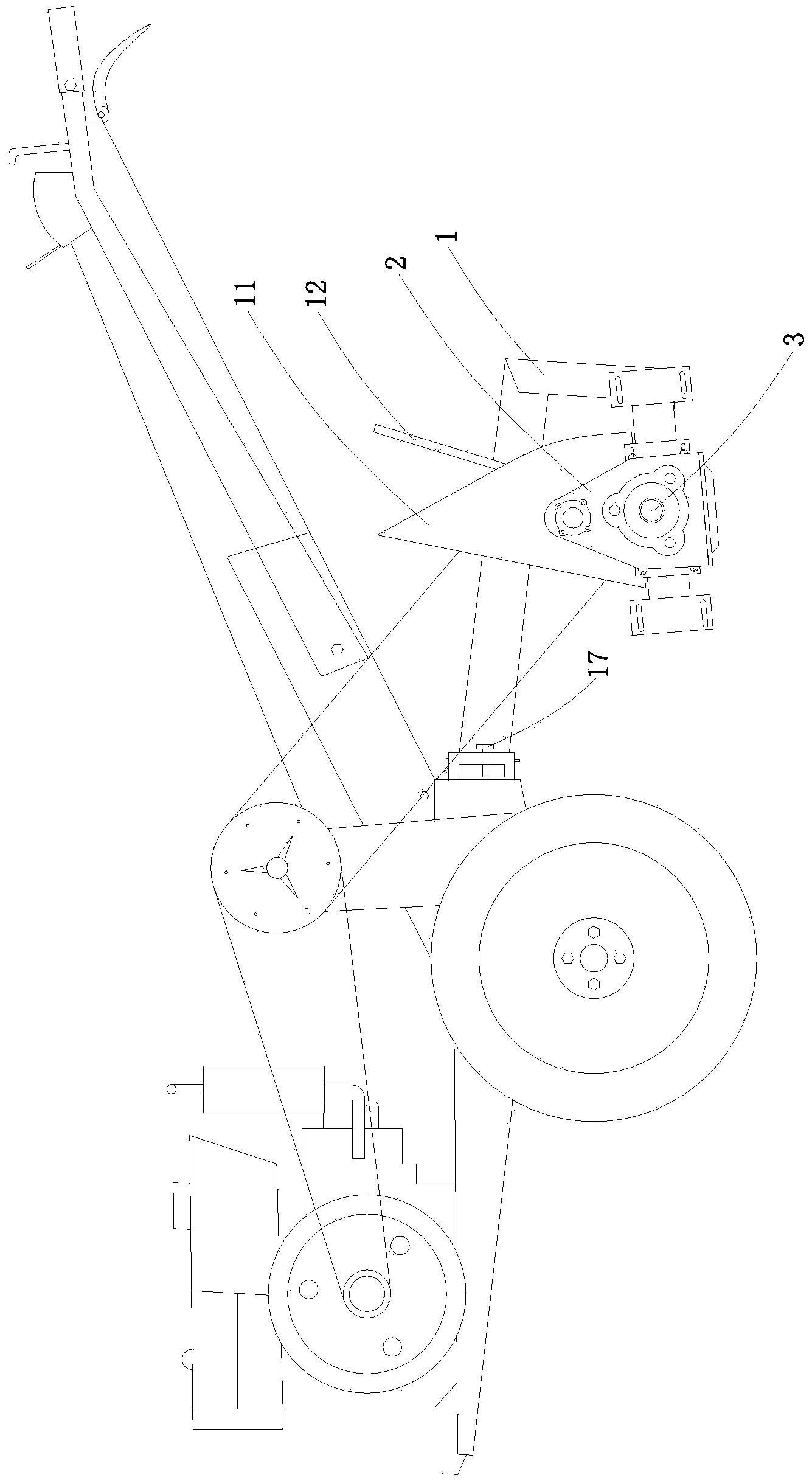

[0024] Example: Combined Figure 1-5 , the ditching machine in this embodiment is suitable for 80-12 small tractors, and the ditching machine is a rear-mounted left side type, because the transmission system of the tractor is located on the left side of the car body, and the ditching machine is placed on the left side to facilitate integration with the tractor. The transmission system is connected, while the engine intake of the tractor is on the right, and the trencher is placed on the left to prevent splashed mud from entering the engine intake and damaging the engine. The ditching machine of the present embodiment comprises:

[0025] An L-shaped frame 1 connected to the hitch frame at the rear of the tractor (that is, the rear section of the frame is bent toward the left side of the tractor), and a gearbox 2 on the left side of the rear of the tractor is arranged on the frame. The input shaft disc of the gearbox is connected with the belt pulley of the tractor through a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com