Atomizing pump device

A technology of spray pumps and pump rods, which is applied in the direction of injection devices, liquid injection devices, and parts of pumping devices for elastic fluids, etc. It can solve the problems of slow pumping, complex structure, high production cost, etc. Stable, easy to use, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

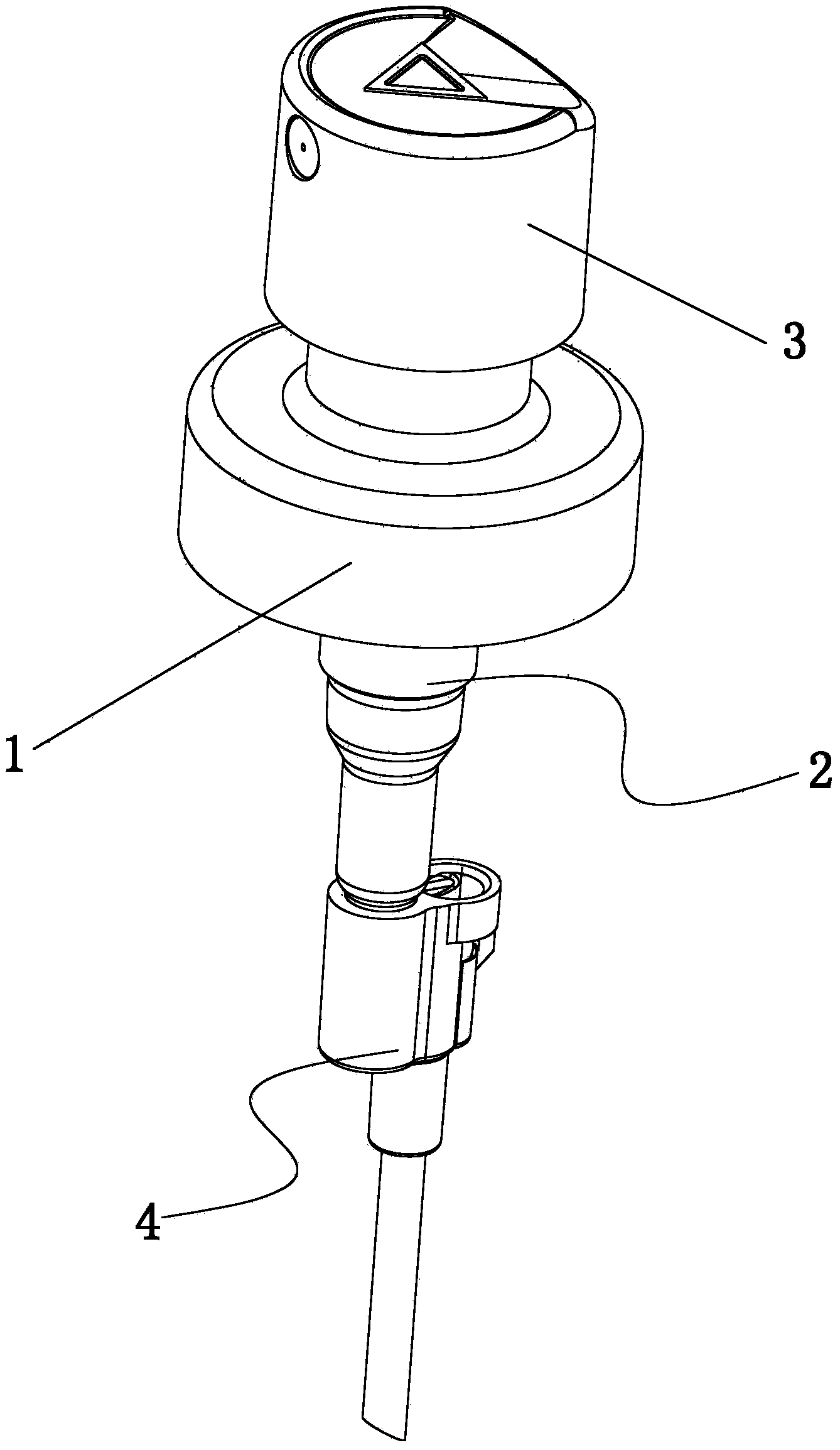

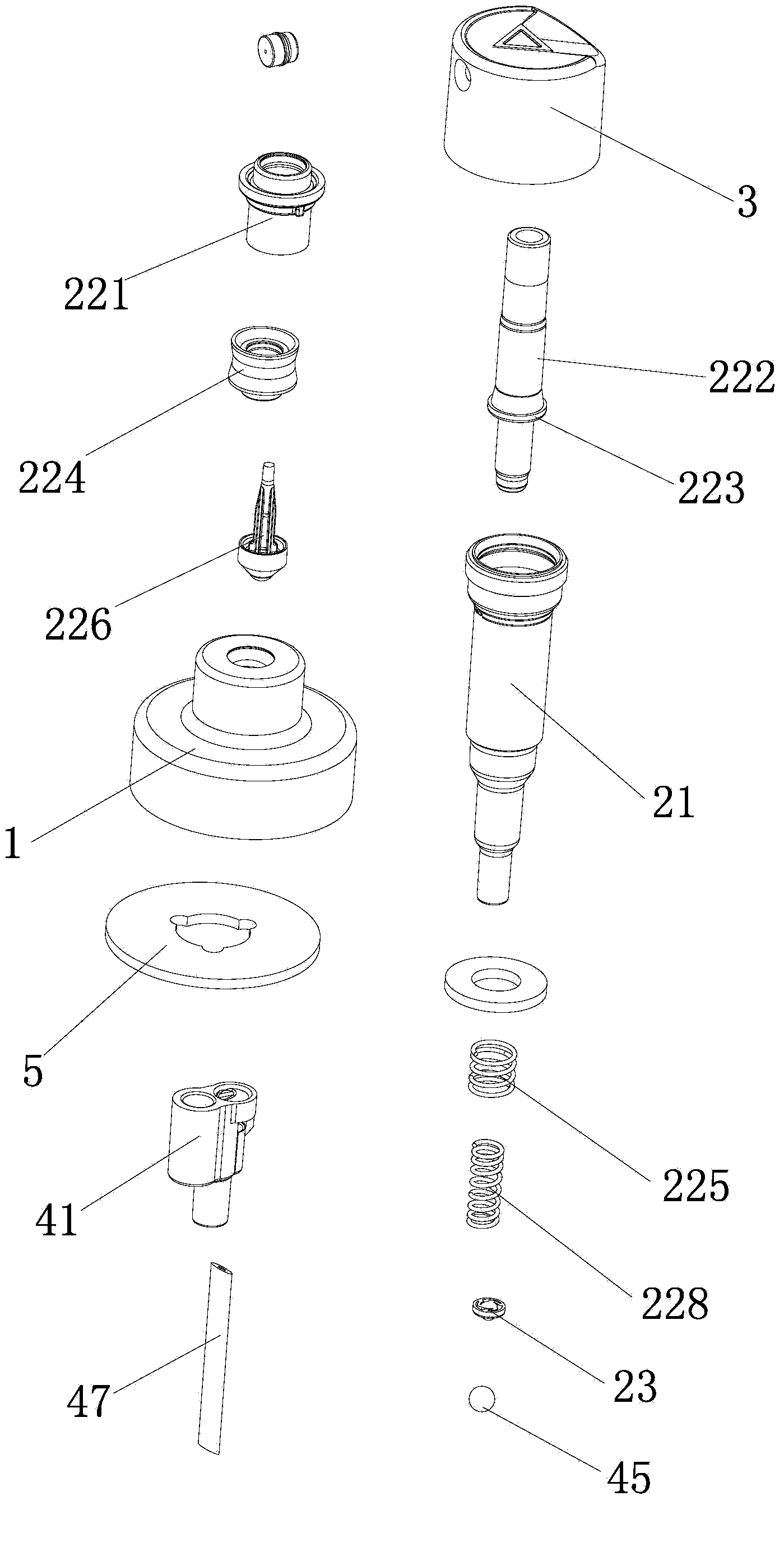

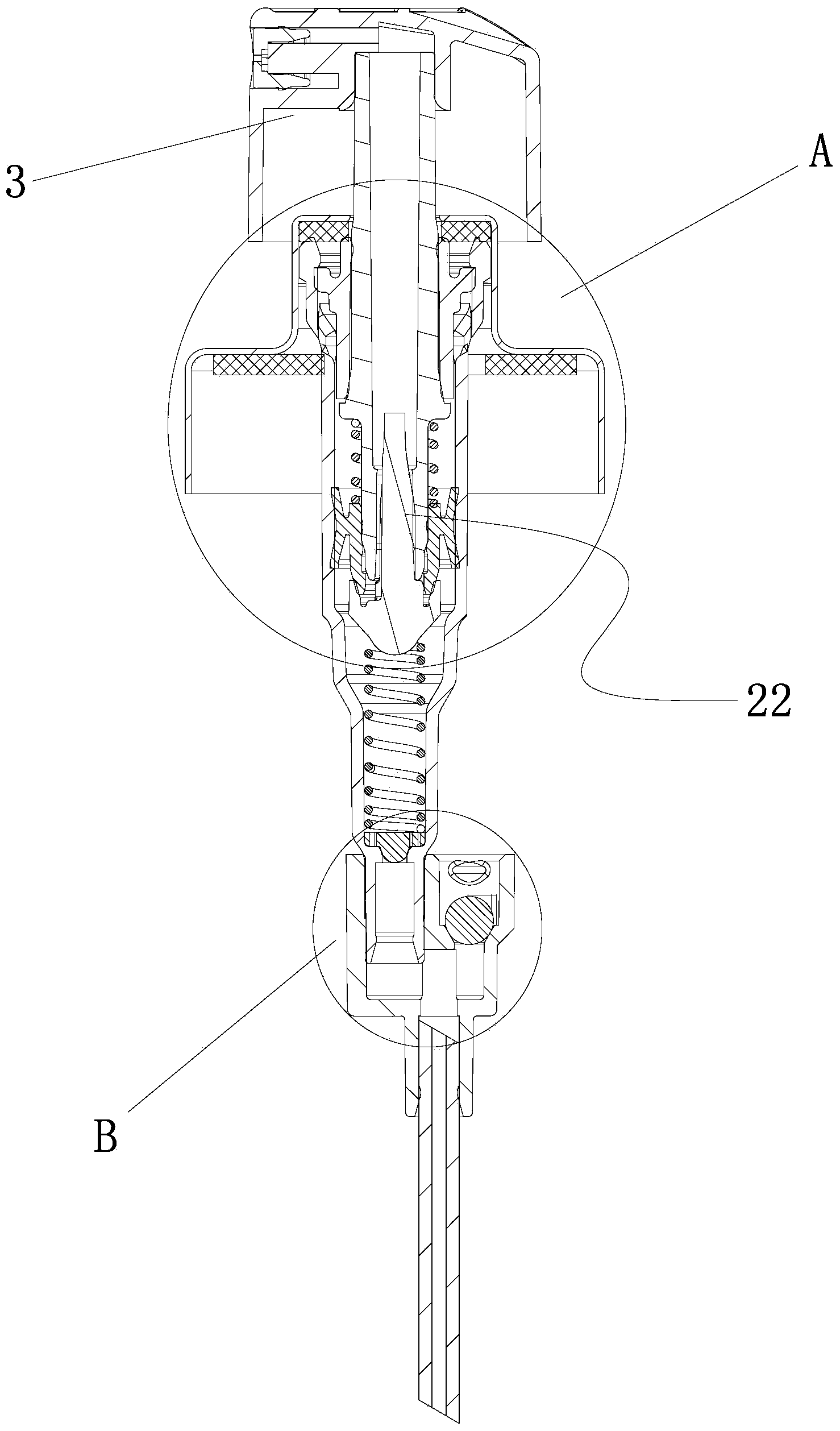

[0031] like Figures 1 to 10 The shown spray pump device includes a sealing cup 1, a pump body assembly 2 is arranged in the sealing cup 1, and a button 3 capable of driving the pump body assembly 2 is arranged on the upper part of the pump body assembly 2, The pump body assembly 2 includes a pump chamber 21, a pump rod assembly 22 is arranged in the pump chamber 21, a check valve 23 is arranged at the lower end of the pump chamber 21, and the pump at the lower end of the check valve 23 The chamber 21 is connected with a gimbal mechanism 4 capable of 360 ° of liquid introduction. The present invention can be used at any angle in a 360-degree direction during use, and is convenient to use.

[0032] like figure 1 , 2 , 3, 5 and 7, the universal seat liquid introduction mechanism 4 described in the present invention includes a universal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com