Intelligent Young modulus measuring instrument

A Young's modulus and measuring instrument technology, applied in the field of intelligent Young's modulus measuring instruments, can solve the problems of easily hurting the operator, inadvertent operation, increasing measurement error, etc., to avoid the calculation process and improve the accuracy , the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

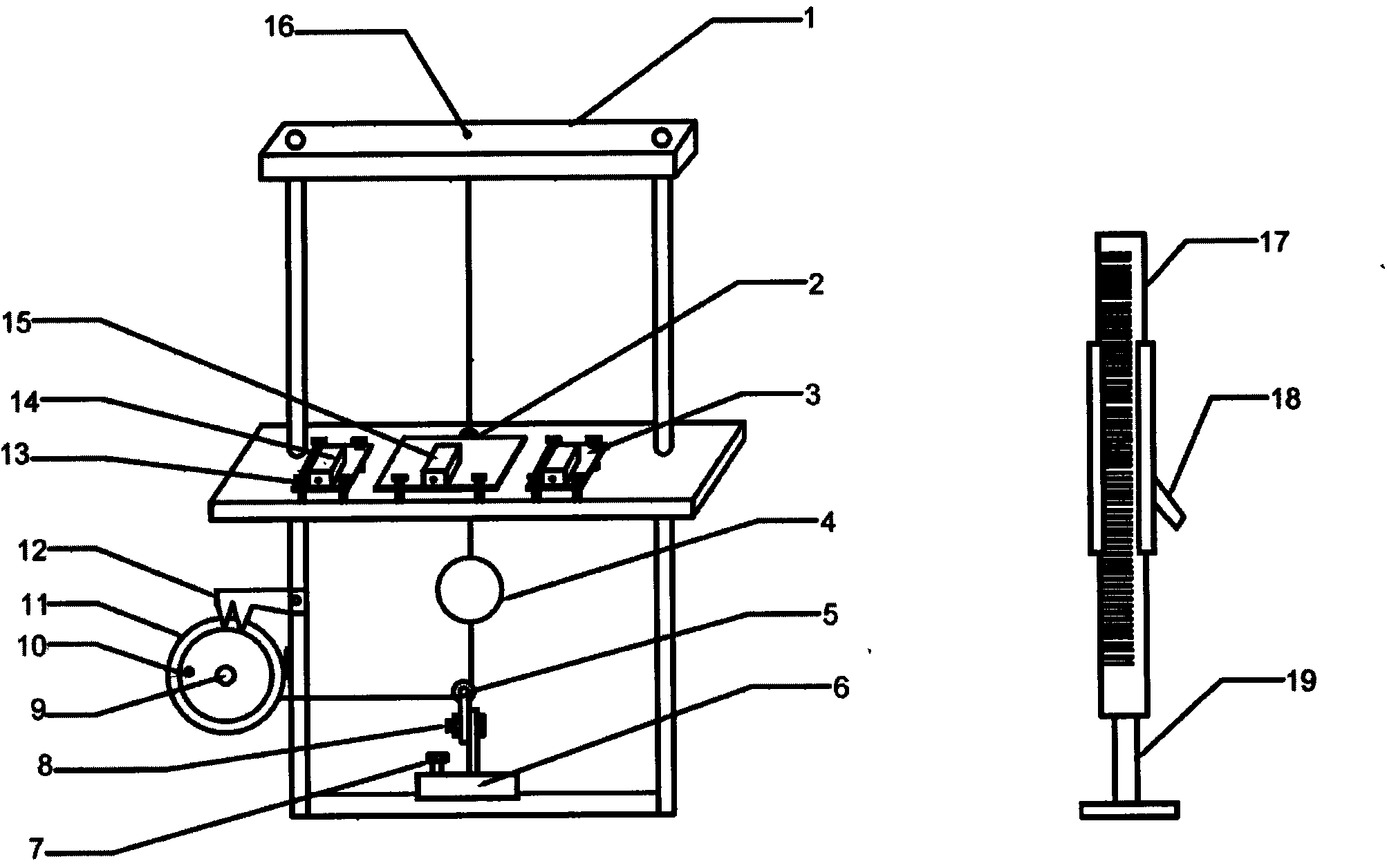

[0013] Present embodiment Young's modulus measuring instrument has following several parts to form:

[0014] 1. Intelligent Young's modulus bracket:

[0015] The intelligent Young's modulus adopts a vertical support, which consists of two vertical steel bars and three horizontal steel plates. The steel plate on the top has a groove, which is used to place the wire head fixing plate; the middle steel plate is used to place the CCD lens and the light lever device, and a hole is opened in the middle of the steel plate, so that the steel wire to be tested and the small platform of the light lever pass through the middle; The steel plate at the bottom has a slideway, and the pulley bracket can slide freely on the slideway, and the pulley bracket is locked by a locking nut.

[0016] 2. Wire head fixing plate

[0017] The steel wire head fixing plate is used for fixing the steel wire to be tested.

[0018] 3. Optical lever device

[0019] A horizontally placed laser generator is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com