Calibration unit and method for critical dimension testing

A technology of key size and correction device, which is applied to the exposure device of the photoengraving process, the photoengraving process of the pattern surface, and the originals used for photomechanical processing, etc. and other problems, to achieve the effect of simplifying the calibration work and ensuring the calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

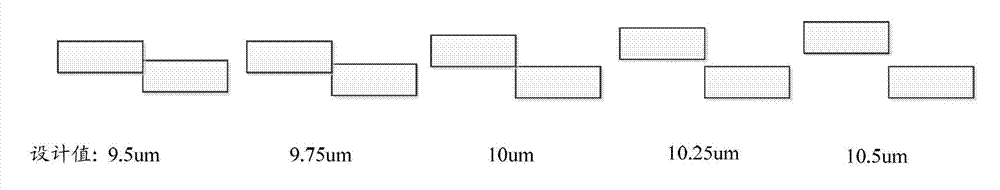

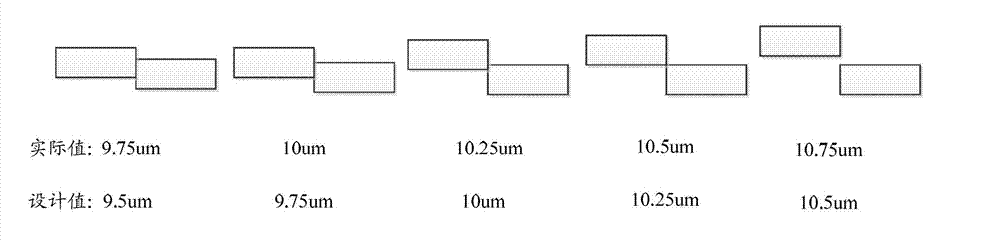

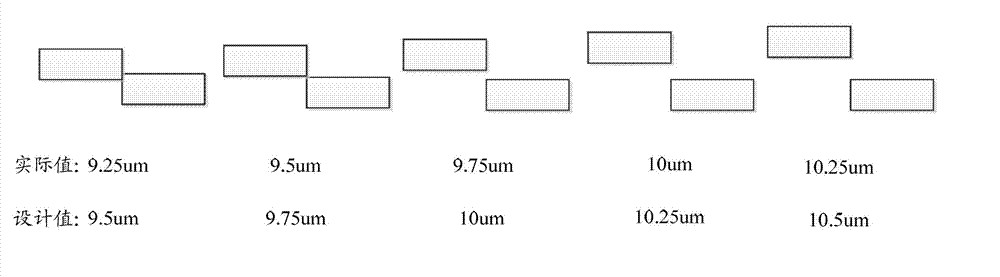

[0028] When performing the test of the graphic critical dimension DICD and the test value correction, or the test of the final critical dimension (Final Inspection Critical Dimension, FICD) after etching and stripping, or the determination of the CD bias (Bias), it can be used in the mask Set a group of Marks on the plate, and this group of Marks will form a group of patterns with photoresist on the glass substrate after the photolithography process. The actual value of DICD can be obtained from this group of patterns, and the actual value of this group of Marks can be obtained. The value is used as the benchmark for DICD test brightness adjustment, thus solving the calibration problem of DICD test value. For example: the actual value of DICD is obtained from a microscopic image acquisition device such as a microscope or an automatic camera with a magnification function, the value is compared with the DICD value detected by the test equipment, and the CD test result is correcte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com