Method for preparing terminal structure by proton irradiation

A technology of proton irradiation and termination structure, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of implantation damage and serious lateral diffusion of N-type wells, achieve small implantation damage, reduce chip terminal area, The effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

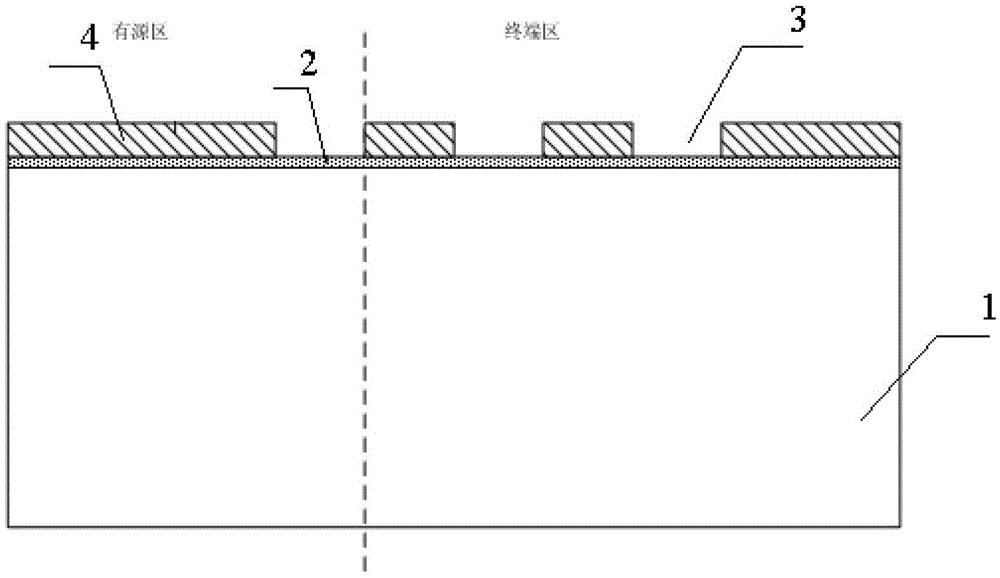

[0043] A method for preparing a terminal structure by proton irradiation provided by an embodiment of the present invention includes the following steps:

[0044] Step SA1: preparing the main junction and P-type field limiting ring of the chip on the substrate;

[0045] Step SA2: preparing a meta-packet structure on the chip forming the main junction and the P-type field limiting ring;

[0046] Step SA3: Combine Figure 8 As shown, after depositing metal electrodes on the chip forming the meta-packet structure, the cathode 18 is formed by etching;

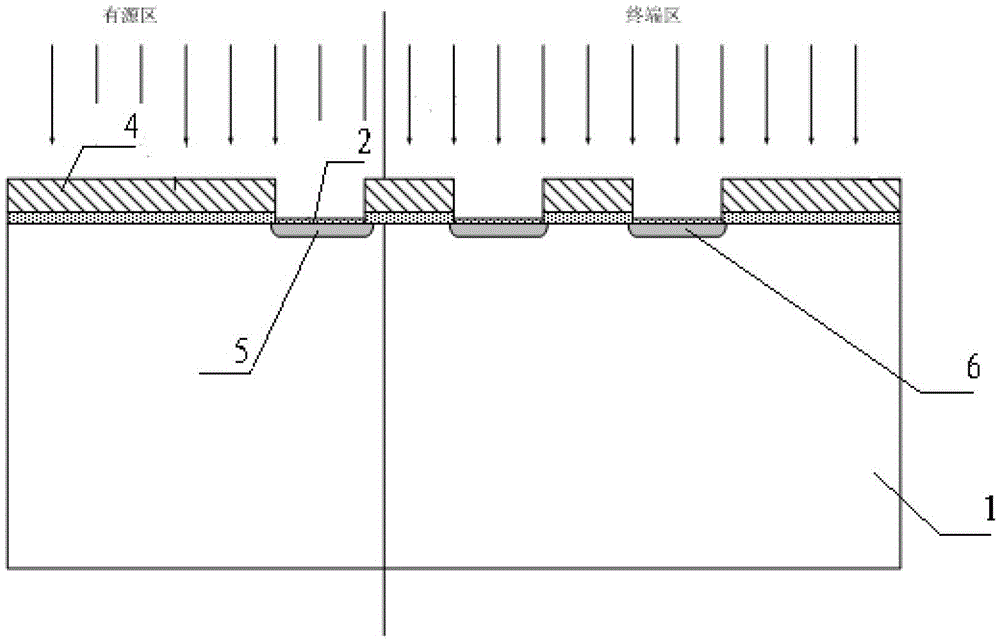

[0047] Step SA4: forming an N-type well by annealing after proton implantation on the chip where the cathode is formed, and completing the front-side process of the chip.

[0048] Step SA5: Combine Figure 11 As shown, after the P-type ion implantation is performed on the back of the chip that has completed the front-side process to form the P-collector 21, a metal electrode is deposited to form the anode 22, and the finished pr...

Embodiment 2

[0057] Step SB1: preparing the main junction and P-type field limiting ring of the chip on the substrate;

[0058] Step SB2: preparing a meta-packet structure on the chip forming the main junction and the P-type field limiting ring;

[0059] Step SB3: Combine Figure 8 As shown, after depositing metal electrodes on the chip forming the meta-packet structure, the cathode 18 is formed by etching;

[0060] Step SB4: forming an N-type well on the chip forming the cathode by annealing after proton implantation, and completing the front-side process of the chip;

[0061] Step SB5: Combine Figure 12 As shown, after the P-type ion implantation is performed on the back of the chip that has completed the front-side process to form the P-collector 21, a metal electrode is deposited to form the anode 22, and the finished product is obtained.

[0062] Wherein, step SA1 prepares the main junction and the P-type field limiting ring of the chip on the substrate including:

[0063] SB11: ...

Embodiment 3

[0070] The difference between this embodiment and Embodiment 1 is that the preparation of the main junction and P-type field limiting ring of the chip on the substrate in step SC2 includes:

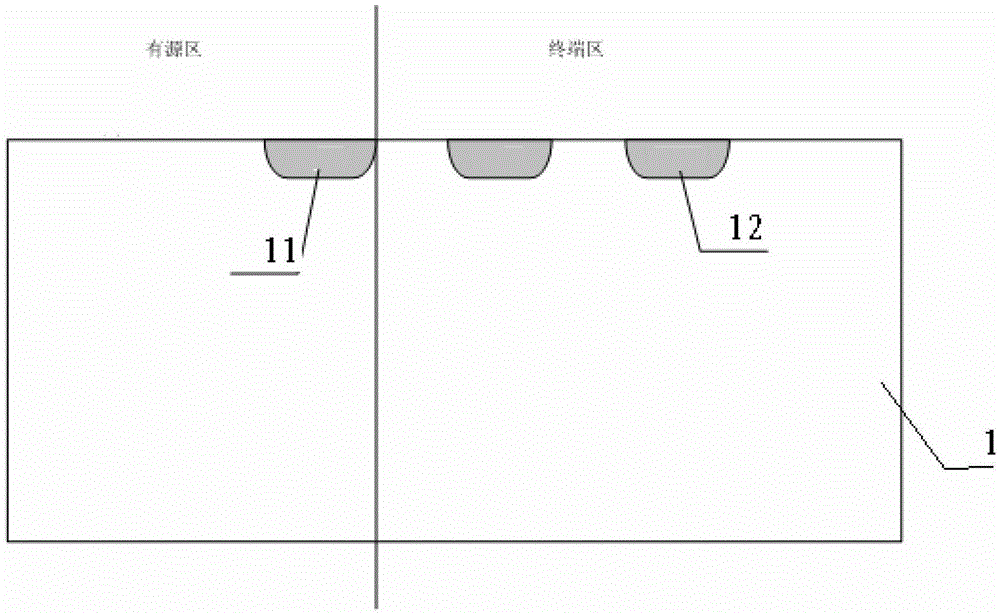

[0071] Step SC21: After the oxide layer on the substrate is etched to obtain an oxide layer window, the substrate is first implanted with low-doped P-type impurities through the oxide layer window to form a low-doped P-type well at the main junction position and The low-doped P-type well in the terminal region is then implanted with highly doped P-type impurities to form a highly doped P-type well at the main junction position and a highly doped P-type well in the terminal region;

[0072] Step SC22: Remove the photoresist from the chip forming the highly doped P-type well at the main junction position and the highly doped P-type well at the terminal region, and perform heat treatment to form a low-doped P-type main junction and a highly doped P-type main junction. Junction, and low-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com