A kind of igbt terminal structure and manufacturing method thereof

A terminal structure, N-type technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large reverse leakage current and junction capacitance, complex thick insulating layer process, and low device current capacity. , to achieve the effect of reduced electric field strength, no increase in process steps, and improved efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

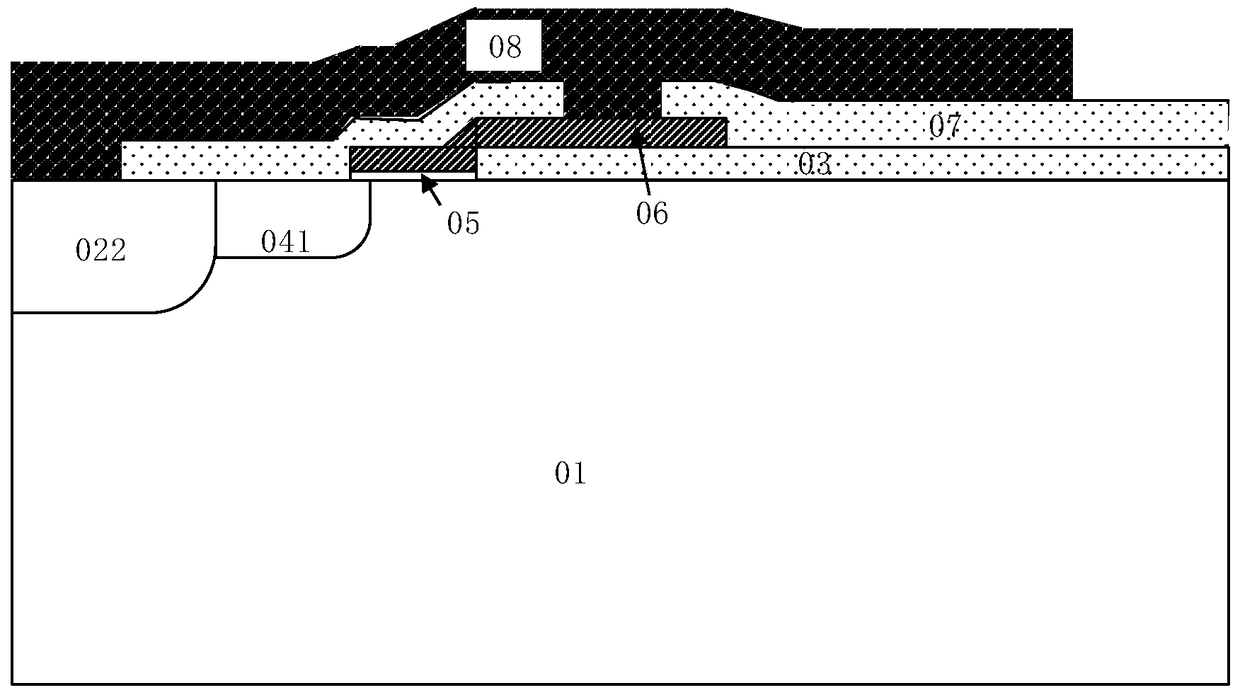

[0036] The schematic diagram of the IGBT terminal structure provided by the present invention is as figure 1 As shown, the IGBT terminal structure is connected to the IGBT active area, and the IGBT terminal structure includes N-type single crystal silicon chip 01, P-type field limiting ring 022, field oxide layer 03, gate oxide layer 05, polysilicon layer 06, boron phosphorus silicon Glass 07 and metal layer 08, the P-type field limiting ring 022 is located in the N-type single crystal silicon wafer 01, and the field oxide layer 03 and the gate oxide layer 05 are arranged in parallel, both located on the surface of the N-type single crystal silicon wafer 01 , the polysilicon layer 06 is located on the surface of the field oxide layer 03, the borophosphosilicate glass 07 is located on the surface of the field oxide layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com