Ultralow forward-voltage-drop Trench Schottky device and manufacturing method

A forward voltage drop, device technology, applied in semiconductor/solid state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing forward voltage drop, low temperature change, etc., to reduce forward voltage drop, terminal length, etc. The effect of reducing and increasing the effective cell area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0043] The present invention is not limited to the following embodiments, and the figures referred to in the following descriptions are provided for understanding the content of the present invention, that is, the present invention is not limited to the device structures illustrated in the figures.

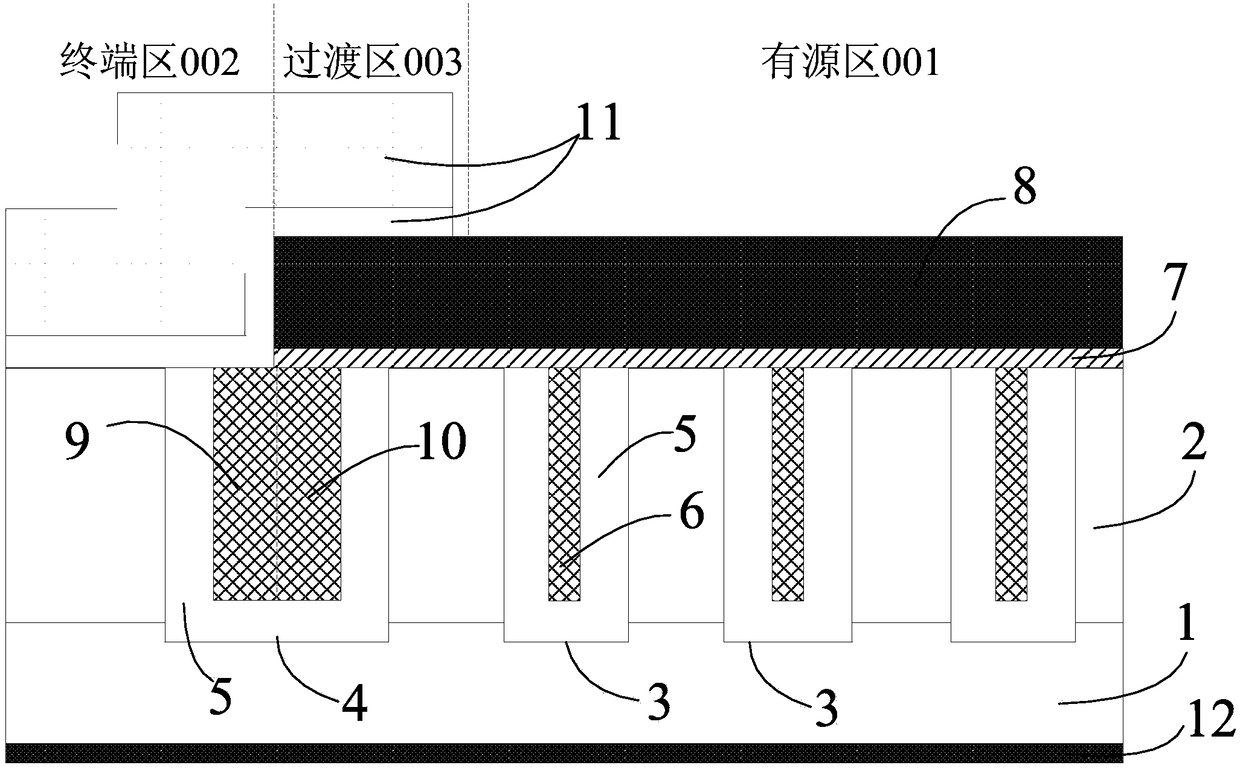

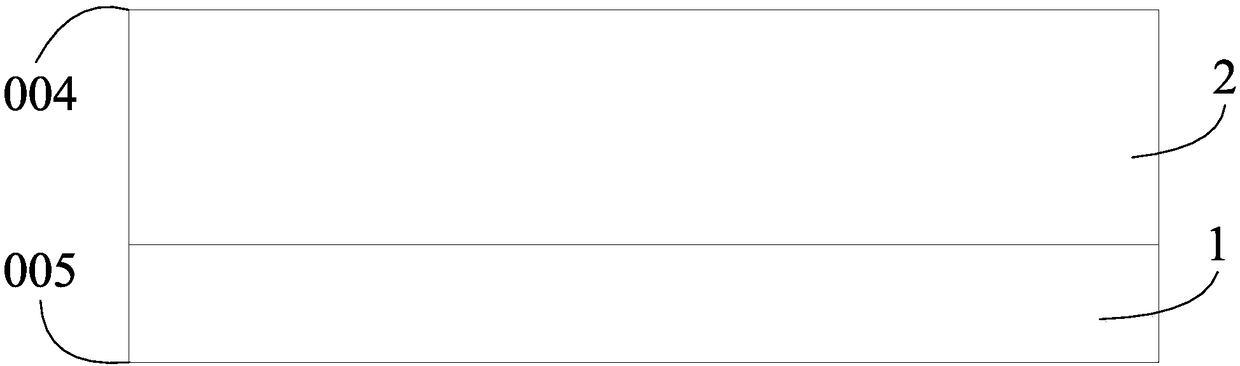

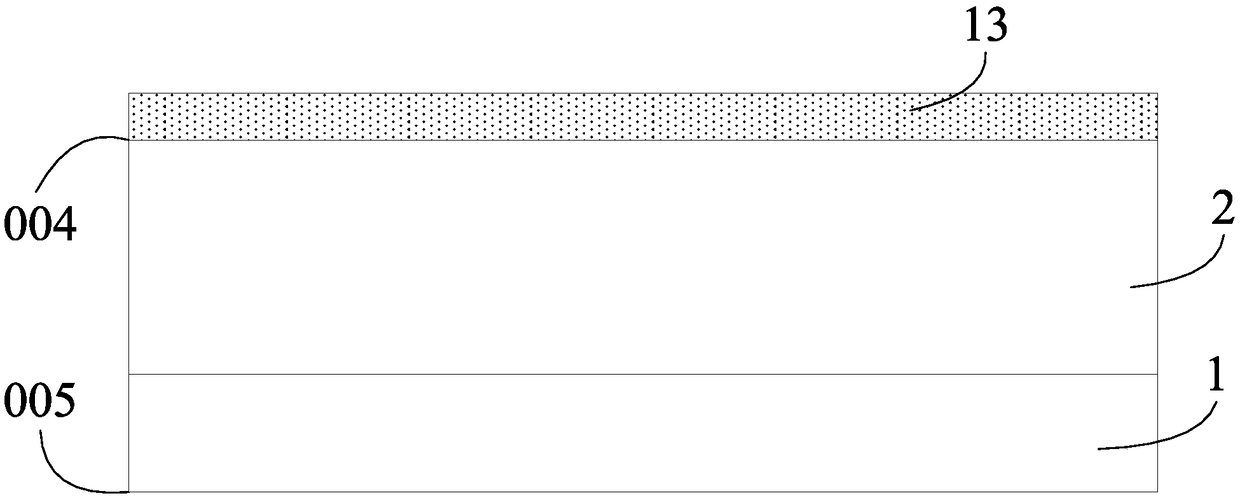

[0044] Such as figure 1As shown, Embodiment 1 takes a 100V Trench Schottky device as an example, a Trench Schottky device with an ultra-low forward voltage drop, including an active region 001 and a terminal region 002 located on a semiconductor substrate, in the Schottky On the top view plane of the base device, the active region 001 is located in the central region of the semiconductor substrate, and the terminal region 002 is located at the outer ring of the active region 001 and surrounds the active region 001; in the cross-section of the Schottky device Above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com