Flexible circuit board and chip package structure

A flexible circuit board and chip technology, applied in circuits, printed circuit components, electrical components, etc., can solve the problems of large impact on circuit board quality, poor pad rigidity, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The flexible circuit board and chip packaging structure provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and four embodiments.

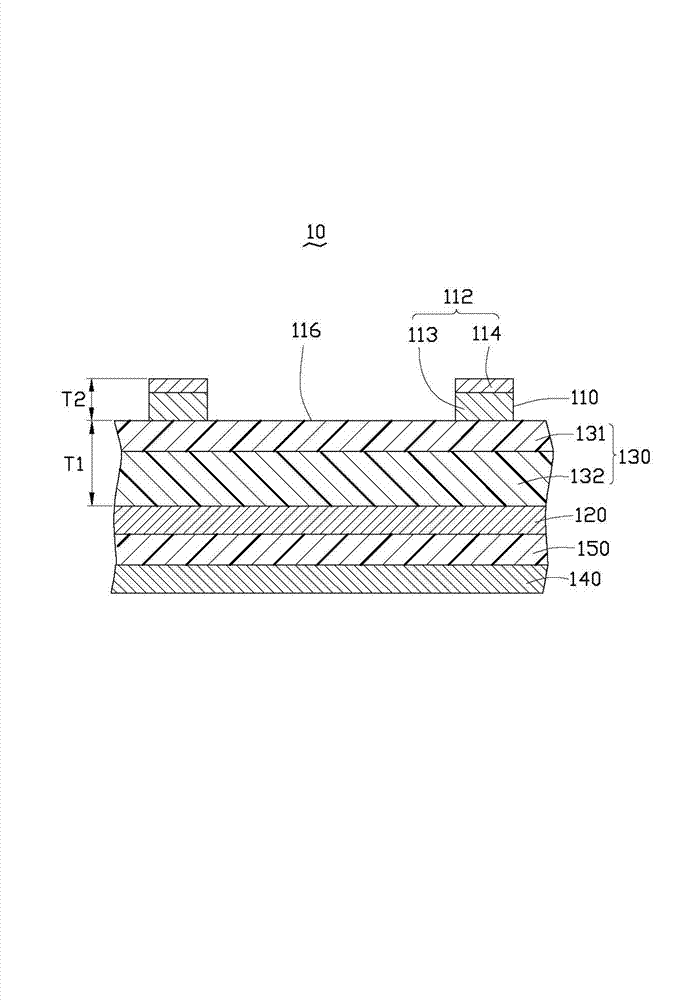

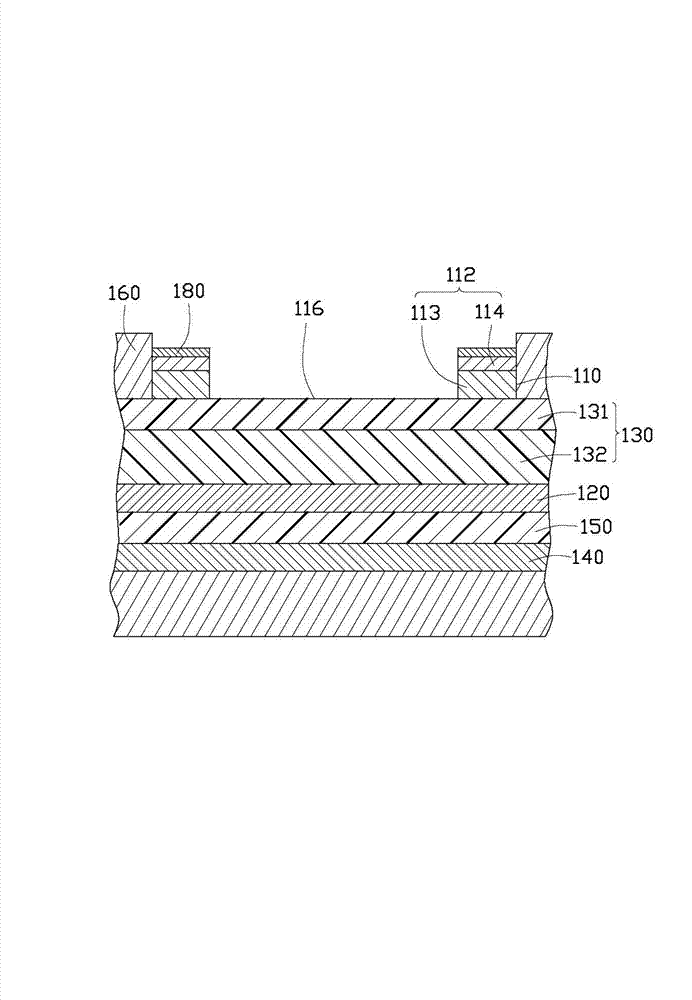

[0018] see figure 1 and figure 2 , the first embodiment of the technical solution provides a flexible circuit board 10, the flexible circuit board 10 includes a first conductive layer 110, a first insulating layer 130, a second conductive layer 120, a second insulating layer 150 and a third conductive Layer 140.

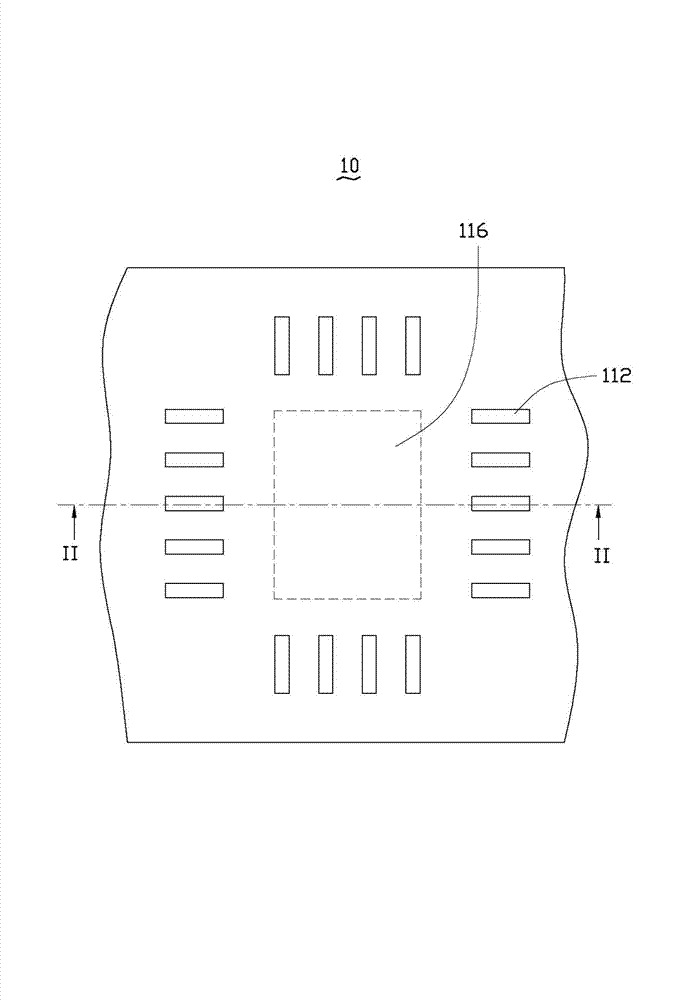

[0019] The first conductive layer 110 includes at least one conductive circuit pattern (not shown in the figure) and a plurality of welding pads 112 . The plurality of pads 112 are used to electrically connect with the semiconductor chip through wires. The area surrounded by the plurality of bonding pads 112 forms a chip bonding area 116 , and the chip bonding area 116 is used for bonding chips. In this embodiment, the die bonding area 116 is a part of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com