Stator double-armature lap winding unit of three-phase brushless synchronous generator

A synchronous generator and three-phase winding technology, applied in the field of motor windings, can solve the problems of high harmonic content and reduce the precision electronic load capacity of induction motors, and achieve the effect of easy implementation and traditional technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

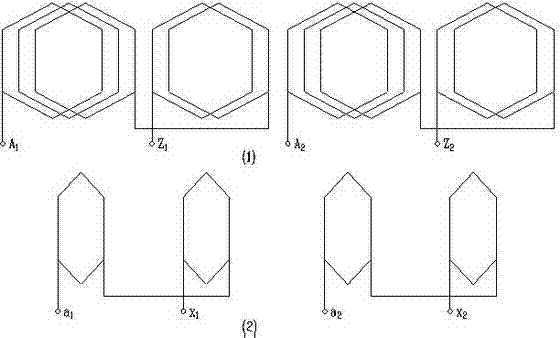

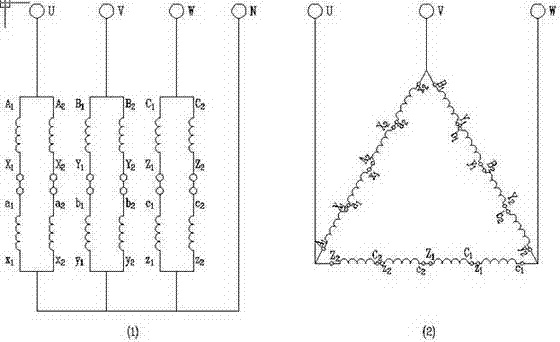

[0012] The present invention is implemented in a stator armature winding of a brushless synchronous generator, the number of stator core slots is 36 slots, the number of poles is 4 poles, the number of phases is 3 phases, the power is 30 kW, the speed is 1500 rpm, and the stator core is inclined by one Slot pitch, two sets of three-phase symmetrical armature windings are arranged in the 36 slots of the stator core, and the corresponding phases of the first set of windings and the second set of windings are the same. Such as figure 1 As shown in (1), the first set of windings has 2 sets of coils per phase, and the first set has 5 coils to form the winding A1X1, including 3 coils 1-8, 2-9, 3-10, and the coil pitch is 7. In addition, there are 2 coils 11-17, 12-18, and the coil pitch is 6. This group of 5 coils has the same number of turns of each coil, which is 11 turns; the second group also has 5 coils to form the winding A2X2 , there are 3 coils 19-26, 20-27, 21-28, the coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com