Water-proof coating system for reflecting solar radiation and water-borne coating for forming decorative and reflective layer in coating system

A technology of waterproof coating and water-based coating, which is applied in the direction of reflection/signal coating, coating, transportation and packaging, etc. It can solve the problem of not being able to effectively meet the needs of consumers, not being able to reflect solar radiation at the same time, and not being able to effectively prevent water infiltration for a long time etc. to achieve good weather resistance, convenient application and strong pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

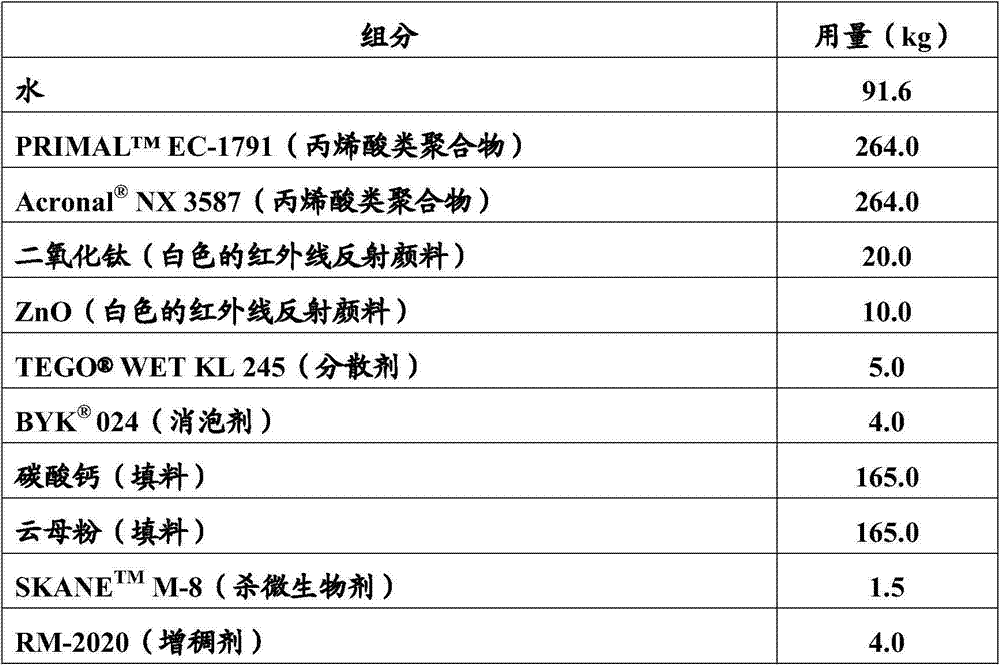

[0099] The formulation of the water-based paint used to form the white reflective waterproof layer in the coating system is shown in Table 1 below, and the pH value of the water-based paint is 9.5.

[0100] Table 1 is used to form the water-based paint 1 of white reflective waterproof layer

[0101]

[0102]

[0103] The formulation of the waterborne paint used to form the gray decorative reflective layer in the coating system is shown in Table 2 below.

[0104] Table 2 is used to form the water-based paint 2 of the gray decorative reflective layer

[0105]

[0106] At a temperature of 32°C and a relative humidity of 20%, the water-based paint 1 was applied at a rate of 0.82kg / m 2 The amount of is sprayed onto colored steel plate (coated with polyester), and cured by self-crosslinking under ambient conditions to obtain a white reflective waterproof layer with a dry film thickness of 400 μm; at a temperature of 32°C and a relative humidity of 20 %, water-based paint ...

Embodiment 2

[0108] The formulation of the water-based paint used to form the white reflective waterproof layer in the coating system is shown in Table 3 below, and the pH value of the water-based paint is 9.5.

[0109] Table 3 is used to form the water-based paint 3 of white reflective waterproof layer

[0110]

[0111] The formulation of the waterborne paint used to form the dark green decorative reflective layer in the coating system is shown in Table 4 below.

[0112] Table 4 is used to form the water-based paint 4 of dark green decorative reflective layer

[0113]

[0114]

[0115] a Purchased from BASF, the same below.

[0116] At a temperature of 23°C and a relative humidity of 50%, the water-based paint 3 was applied at a rate of 0.82kg / m 2 The amount of is sprayed onto colored steel plate (coated with polyester), and cured by self-crosslinking under ambient conditions to obtain a white reflective waterproof layer with a dry film thickness of 400 μm; at a temperature of...

Embodiment 3

[0118] The formulation of the waterborne paint used to form the white reflective waterproof layer in the coating system is shown in Table 5 below, and the pH value of the waterborne paint is 9.5.

[0119] Table 5 is used to form the water-based paint 5 of white reflective waterproof layer

[0120]

[0121]

[0122] The waterborne paints used to form the dark green decorative reflective layer in the coating system are shown in Table 4 above.

[0123] At a temperature of 32°C and a relative humidity of 20%, the water-based paint 5 was applied at a rate of 1kg / m 2 The amount of is sprayed onto colored steel plates (coated with polyester), and cured by self-crosslinking under ambient conditions to obtain a white reflective waterproof layer with a dry film thickness of 500 μm; at a temperature of 32°C and a relative humidity of 20 %, water-based paint 4 at 0.56kg / m 2 The amount of is sprayed onto the white reflective waterproof layer, and UV cured under ambient conditions to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com