Electric motor

A technology of electric motors and motor shafts, applied in the direction of electric components, electromechanical devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

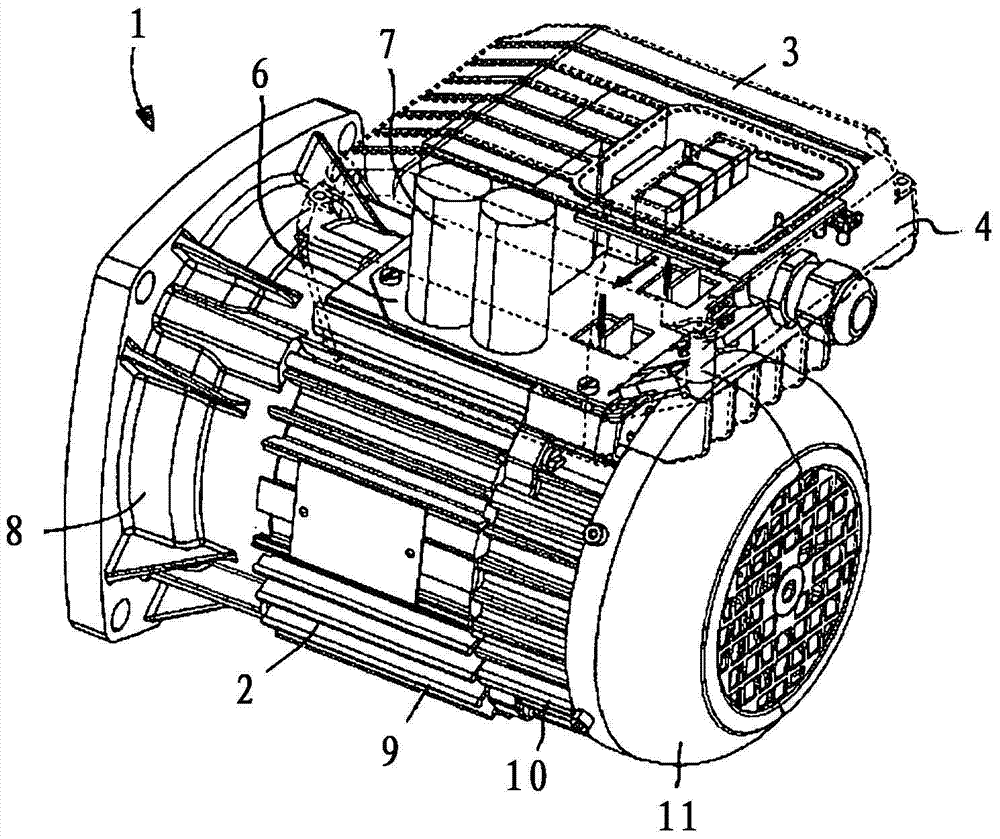

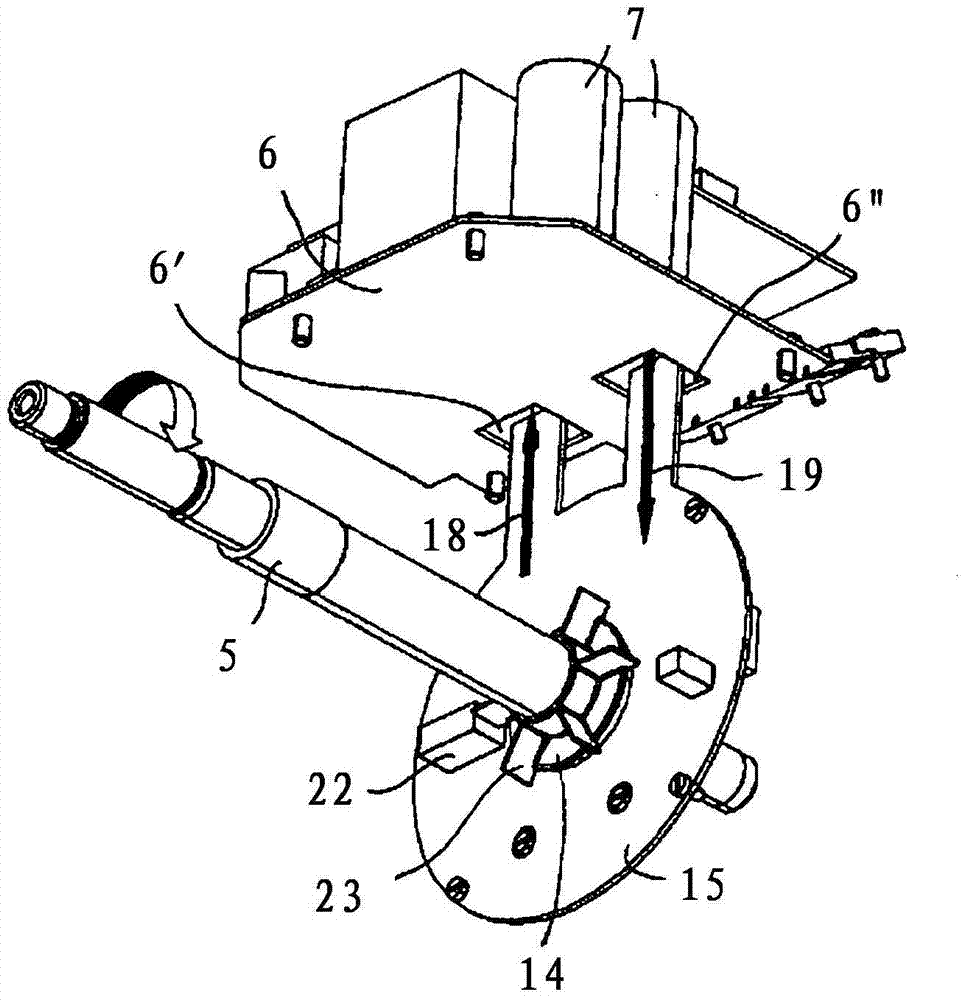

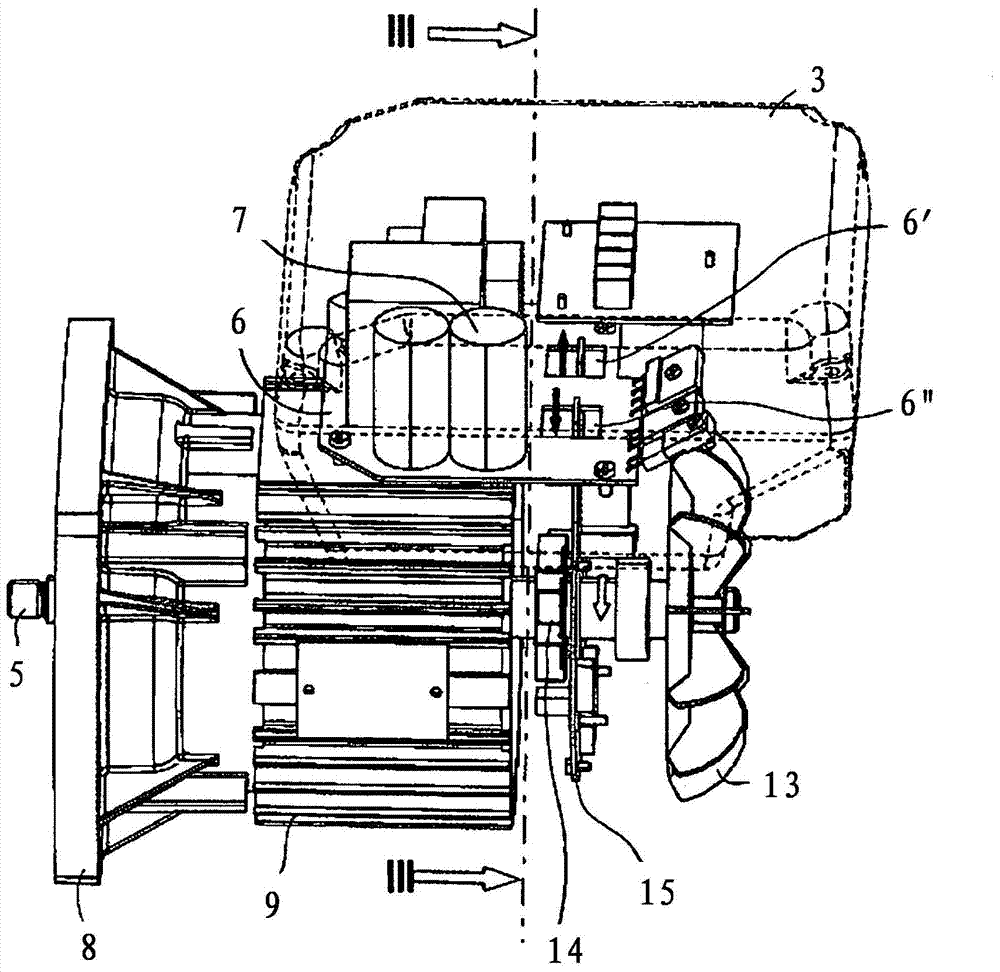

[0022] The electric motor 1 can be designed, for example, as a synchronous motor and comprises a housing 2 and a terminal box 3 which is fastened to the upper side of the circumferential wall of the housing 2 in a non-positive or form-fitting manner.

[0023] The terminal box 3 has a pot-shaped wall profile 4 , inside which extends a circuit board 6 extending parallel to the motor shaft 5 , said circuit board being equipped with electronic components 7 . The electronic components 7 arranged on the printed circuit board 6 can form a supply voltage input circuit structure and / or a rectifier.

[0024] The housing 2 of the electric motor 1 has an A-bearing end shield 8 , a housing central part 9 , a B-bearing end shield 10 and a fan housing 11 , which are arranged coaxially one behind the other in the axial direction. The motor shaft 5 is arranged in the housing 2 constructed in this way, the stator and the rotor are arranged in the area of the housing central part 9 , the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com