Mandrel of pressing type dental high-speed turbine handpiece

A pressing, dental technology, applied in dentistry, dental drilling, medical science and other directions, can solve the problems of short service life, easy wear of the chuck, unreasonable structure of the mandrel, etc. Strong holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

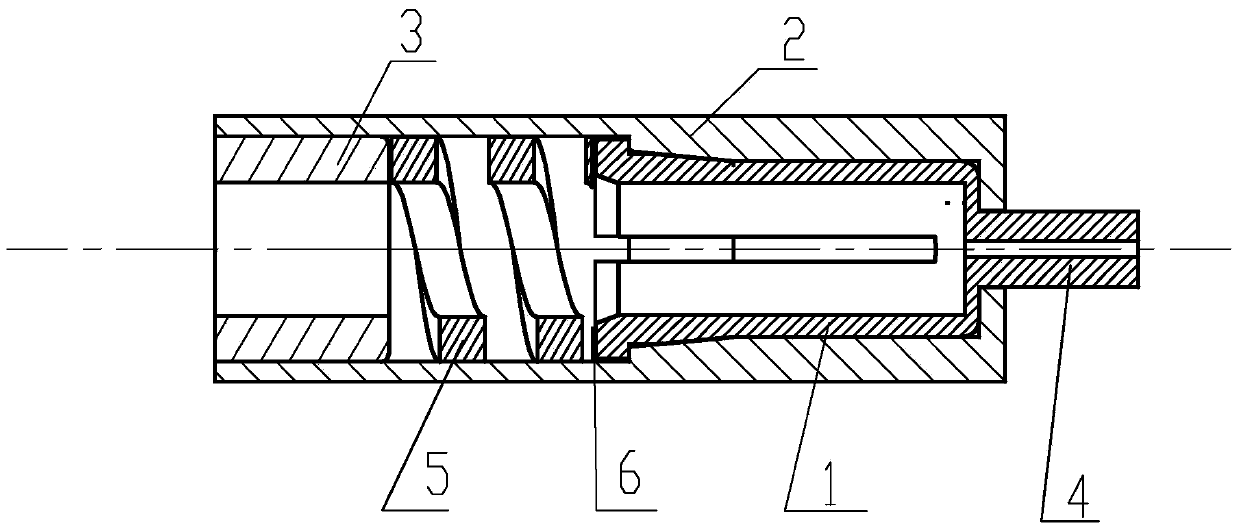

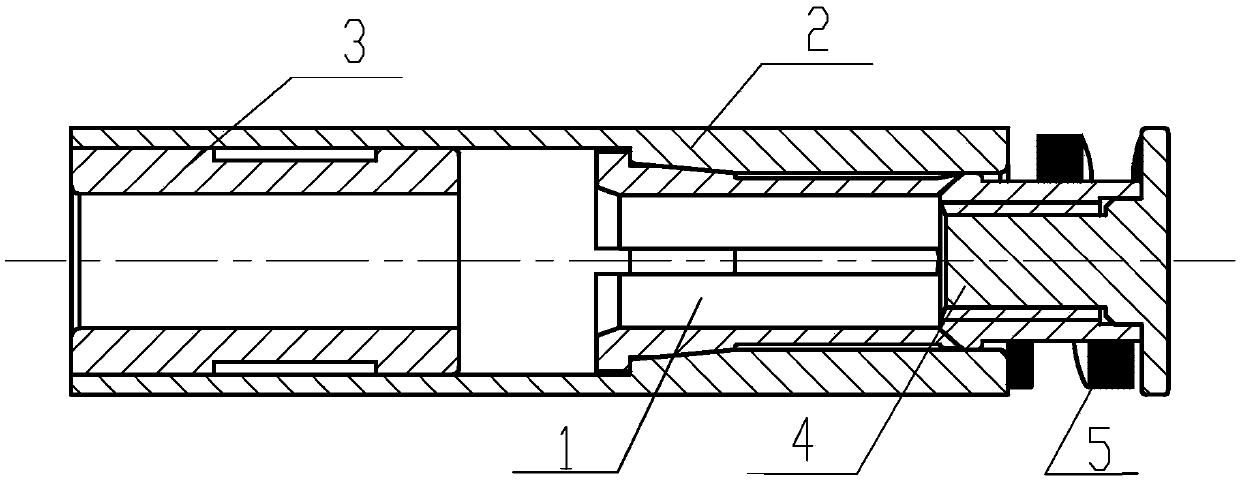

[0017] Such as figure 1 As shown, the mandrel of a press-type dental high-speed turbine handpiece of the present invention includes a hollow cylindrical bushing 2 with openings at both ends and a four-leaf spring 1 nested in the bushing 2, and the front part of the bushing 2 is embedded A hollow cylindrical core shaft meson 3 with open ends is sleeved, and the four-lobed spring 1 is nested at the rear of the sleeve 2 . The four-leaf spring 1 is connected with a rebound device that controls its forward and backward movement to realize the disassembly and assembly of the bur. The rebound device includes a spring 5 and a pressing member 4, and the spring 5 is a rectangular spring. Described spring 5 is arranged between mandrel meson 3 and four-lobe spring 1, and one end of spring 5 is stuck on the rear end of mandrel meson 3, and the other end is stuck on the front end of four-lobe spring 1, and described pressing piece 4 and The rear end of four leaf spring 1 is connected. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com