Resist stripper regeneration methods and devices

A regeneration device and resist technology, applied in the direction of separation methods, chemical instruments and methods, evaporator accessories, etc., can solve the problems of not being practical, not cheap, costly, etc., and achieve the effect of preventing temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The method and apparatus for regenerating the resist stripping solution of the present invention will be described below using the drawings. In addition, the following description is just description of one embodiment of this invention, It is not limited to the following description, It can change in the range which does not deviate from the summary of this invention.

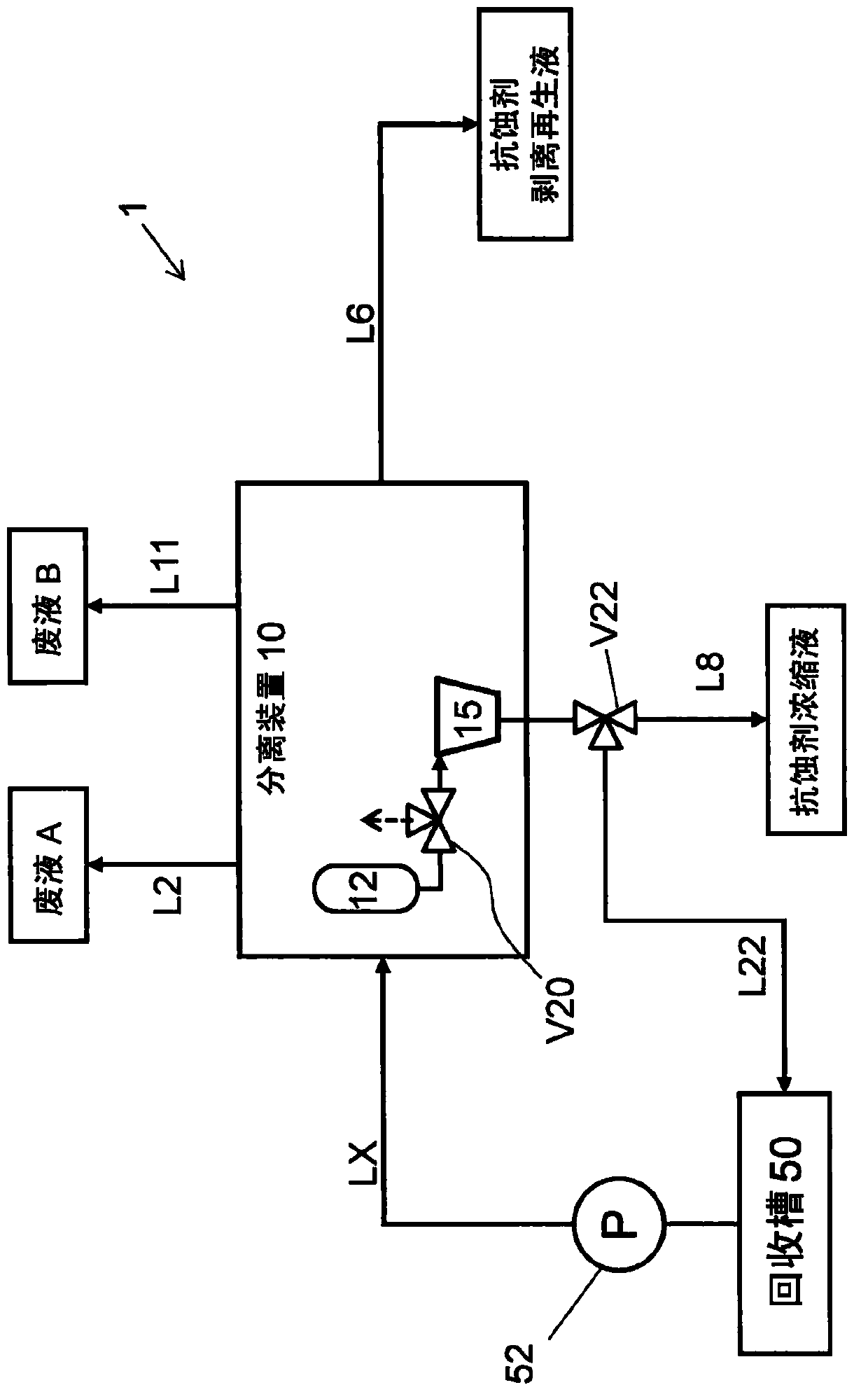

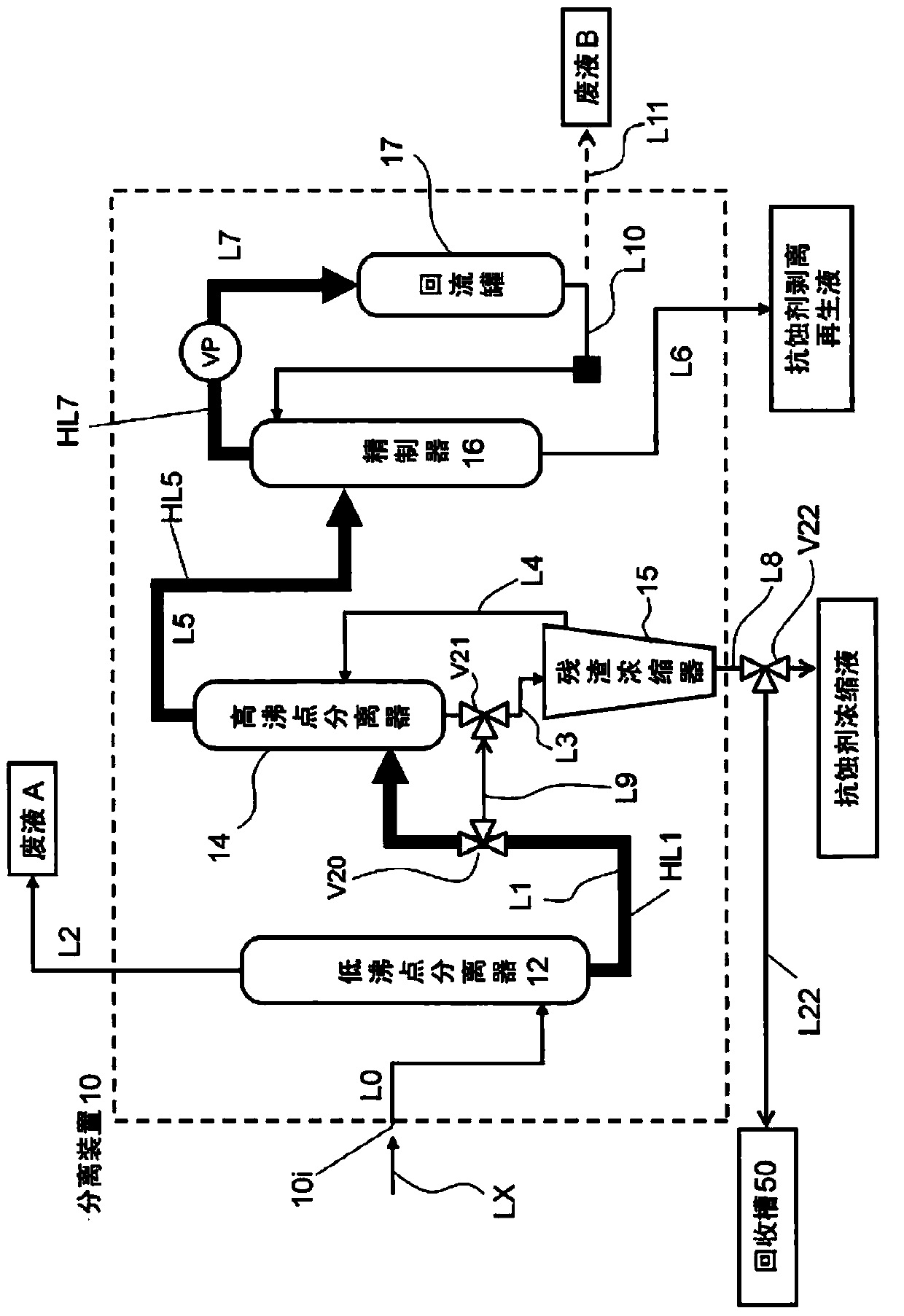

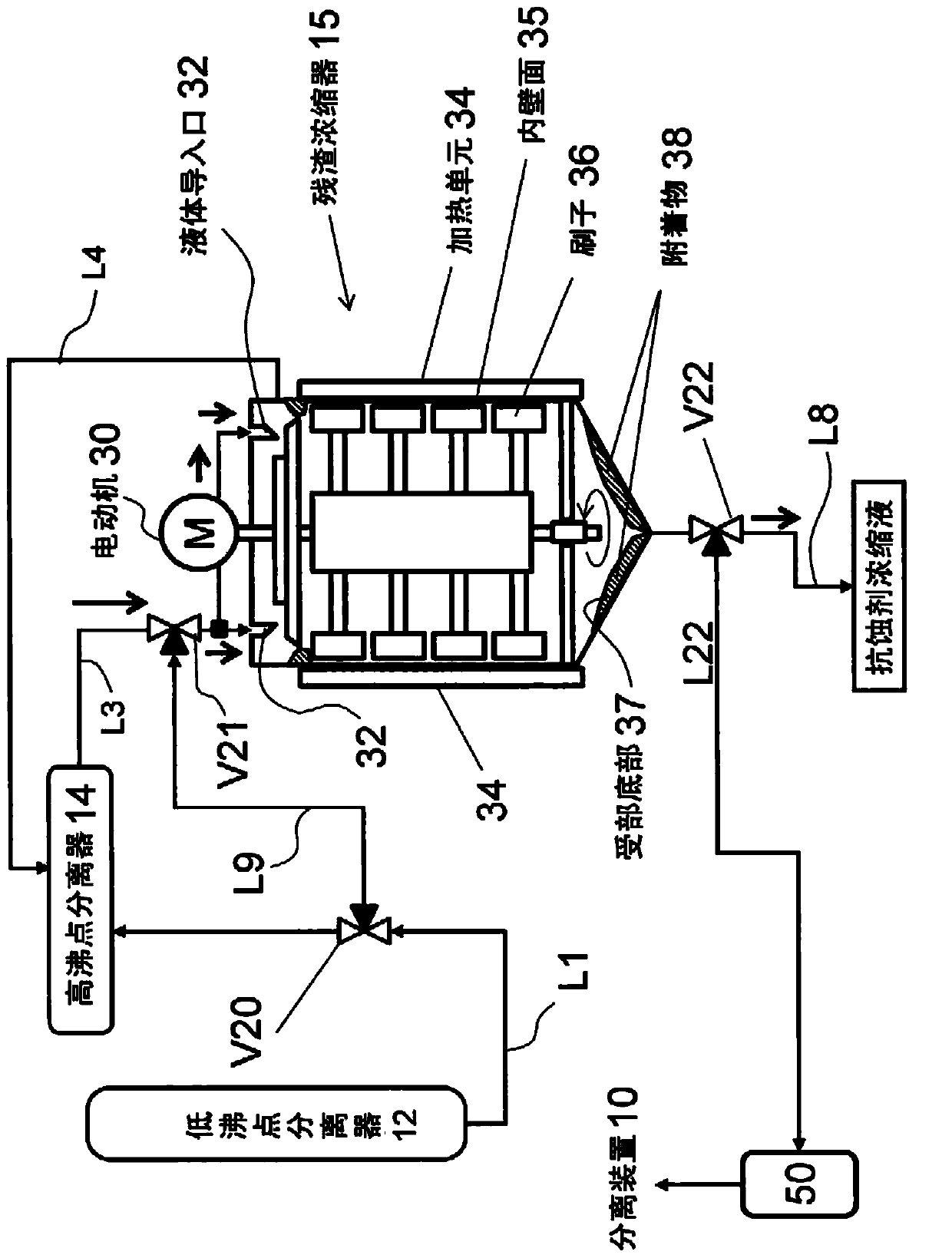

[0057] first, figure 1The outline of the regeneration apparatus 1 of the resist stripping solution of the present invention is shown in . The regenerating device 1 of the present invention includes: a pipe LX that transfers the used resist stripping solution from a recovery tank 50 that stores the used resist stripping solution; a separation device 10 that discharges the used resist stripping solution Resist concentrated liquid, resist stripping regeneration liquid, waste liquid A mainly composed of water, and waste liquid B. In addition, the separation device 10 includes a low-boiling point separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com