Electric demisting method and device for capturing and collecting fine particulate matters in flue gas generated after wet desulphurization

A fine particulate matter and wet desulfurization technology, applied in the field of electrostatic demisting, can solve the problems of limited ability of electrostatic precipitators to capture PM2.5, easy corrosion of chemical fibers, shortened service life of equipment, etc. Equipment height and floor area, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

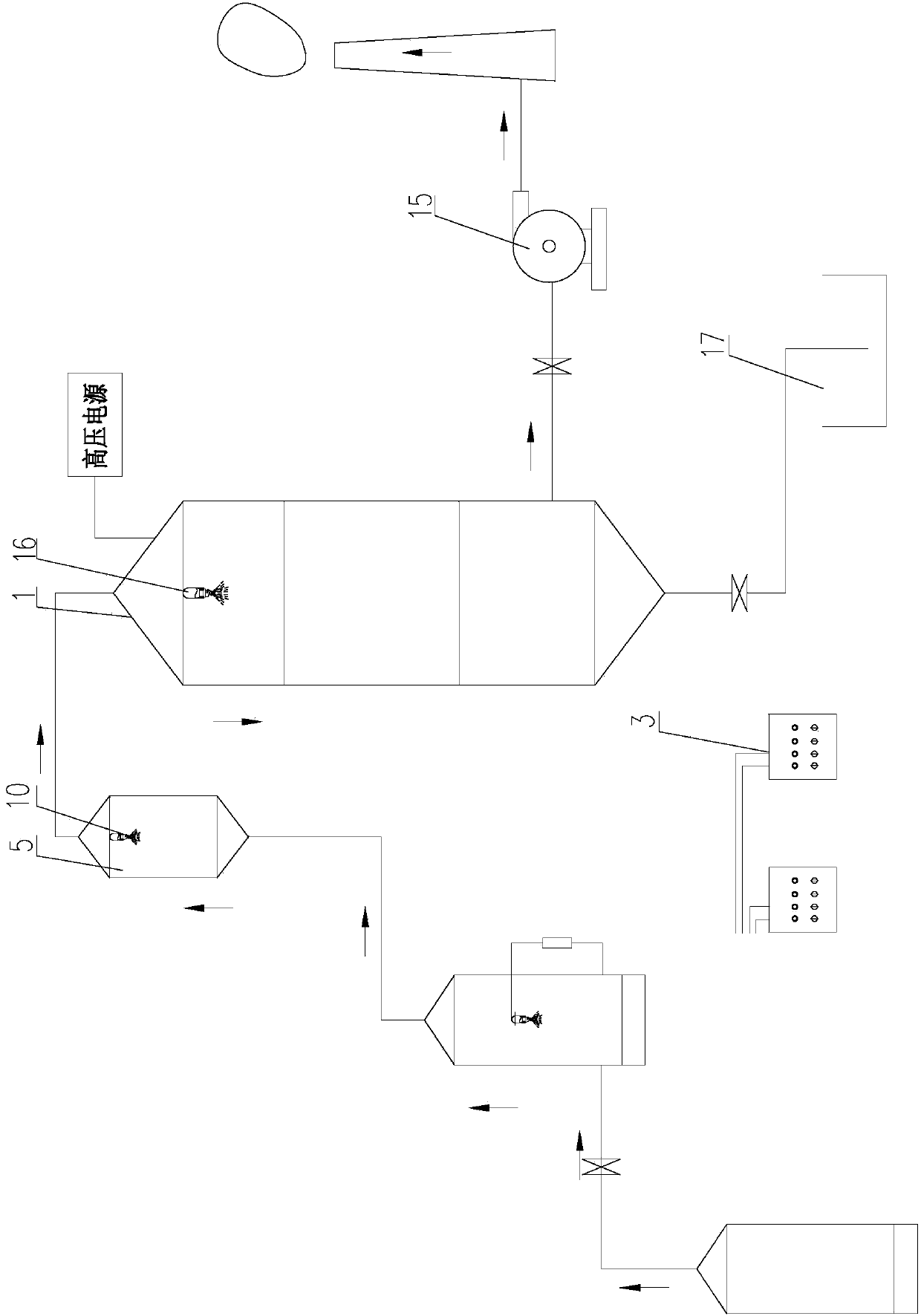

[0025] Embodiment 1 of the present invention: a method for trapping fine particles in flue gas after wet desulfurization, the flue gas produced by burning coal enters the desulfurization tower through the pipeline, and the flue gas reacts with the limestone slurry sprayed from the desulfurization tower, Saturated wet flue gas is produced, and the flue gas carries smaller particles of slurry droplets and evaporated water mist along the pipe into the flue gas activation chamber, where surfactants are sprayed in the flue gas activation chamber, and the water mist can be enhanced by surfactants. The surface tension of the fog and the wettability of the surface of the fine particles are improved. The fine particles collide with the surfactant to agglomerate and become larger and enter the electrostatic demist device. The electric field formed in the electrostatic demist device charges the agglomerated fine particles and moves to The direction of the dust collector moves, and the sus...

Embodiment 2

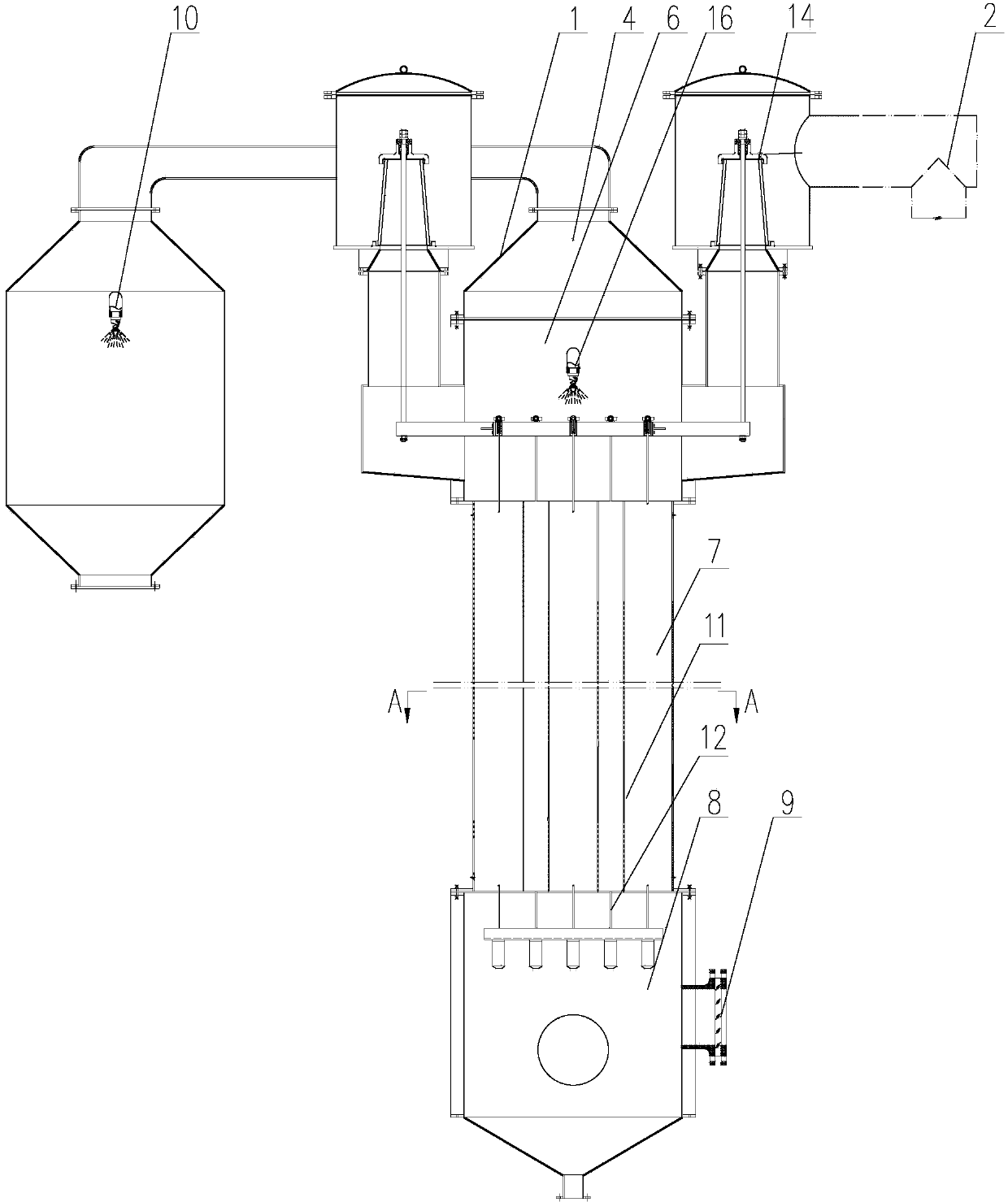

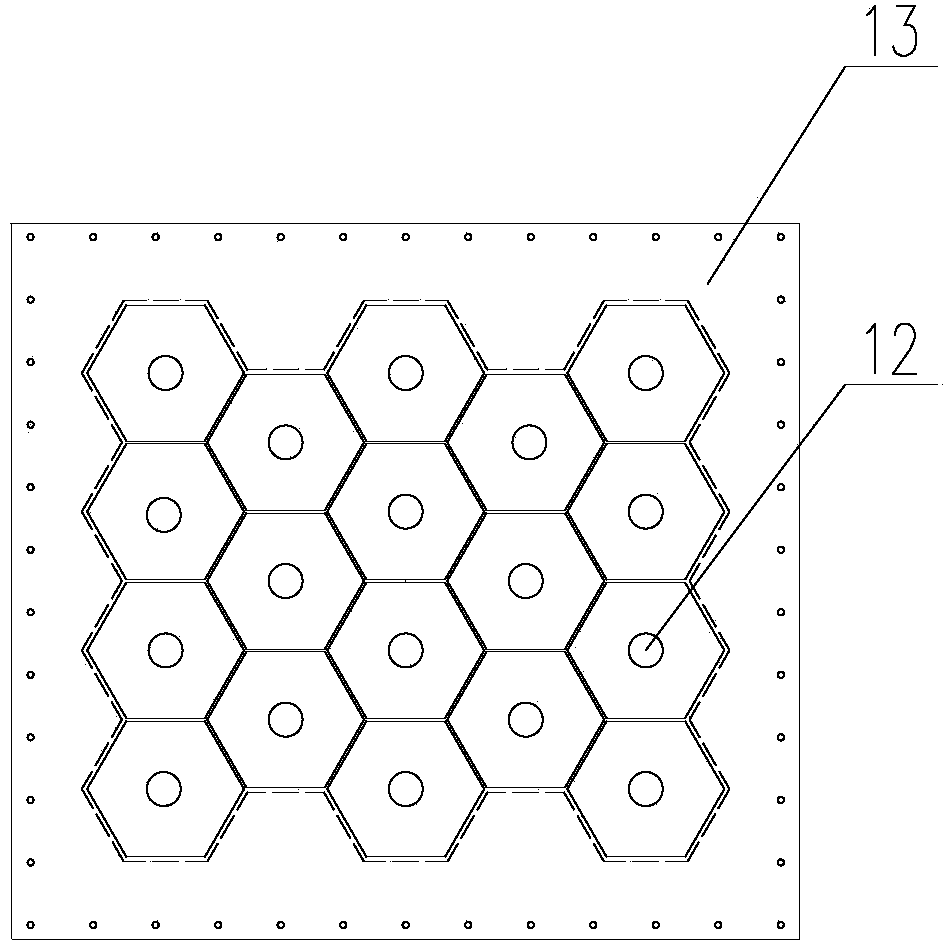

[0027] Embodiment 2 of the present invention: as Figure 4A system using an electric defogging device is shown, including an electric defogging device body 1, a power supply system 2, and a control system 3, including an electric defogging device body 1, a power supply system 2, and a control system 3, wherein the electric defogging device The main body 1 is provided with an airflow distribution device 4, an air intake chamber 6, a defogging chamber 7 and an exhaust chamber 8 in order from top to bottom. In the channel and connected with the air distribution device 4. A spraying device 10 is arranged in the flue gas activation chamber 5 . An electric demister 11 is provided in the demister chamber 7 . The electrostatic demister 11 includes a discharge electrode 12 and a dust collection electrode 13, the discharge electrode 12 is connected with a high voltage power supply 14, the discharge electrode 12 adopts a rigid structure, and the dust collection electrode 13 adopts cond...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap