Self-cooling technology and machining method of metal plate spiral stepped blade twist drill

A processing method, twist drill technology, applied in twist drills, metal processing equipment, parts of boring machines/drilling machines, etc., can solve problems such as inability to achieve cooling effect, twist drills are not durable, and the hardness of the cutter head is reduced, so as to improve heat dissipation Effect, efficiency improvement, and effect of reducing cutting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

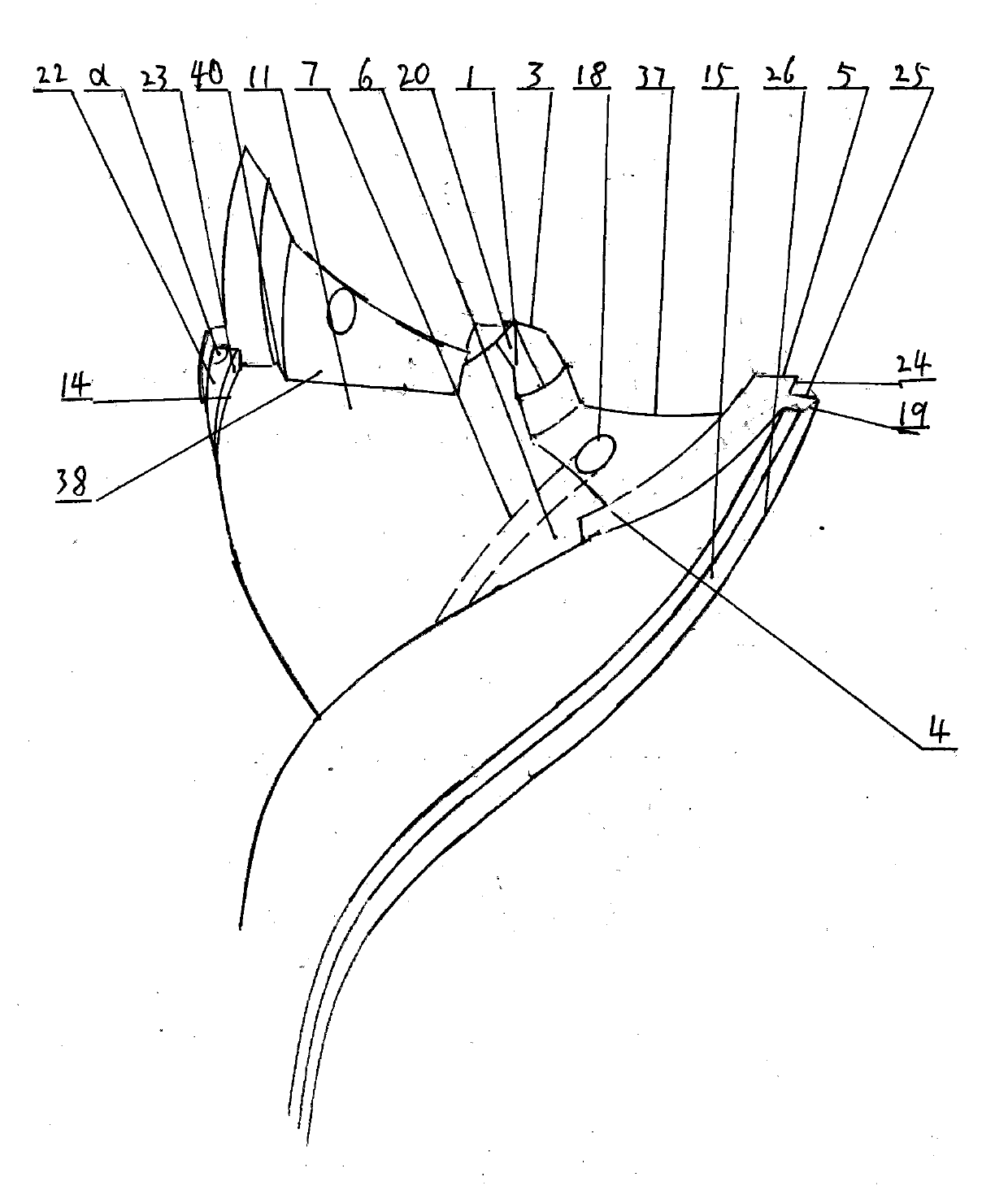

[0034] Such as figure 1 , Figure 7-Figure 10 , Figure 11-Figure 14 As shown, the self-cooling technology and processing method of the sheet metal spiral stepped edge twist drill of the first embodiment of the present invention mainly relate to the sheet metal twist drill used in mechanical processing, wherein, Figure 7 The drill point in the axial center is not chamfered, so the chisel edge is larger and the cutting resistance is also larger. Figure 8 Although the drill point in the axial center is chamfered, there is still a reduced chisel edge, and the cutting resistance is relatively Figure 7 reduced a lot, Figure 9-Figure 10 After chamfering, the drill point in the axial center has become a sharp edge without a chisel edge, and the cutting resistance is the smallest. Figure 11-Figure 12 A cooling hole 16 is set on the tapered shank 12 and straight shank 12 of the twist drill, and the other end of the cooling hole 16 is integrated with the tapered shank 12 and th...

Embodiment approach 2

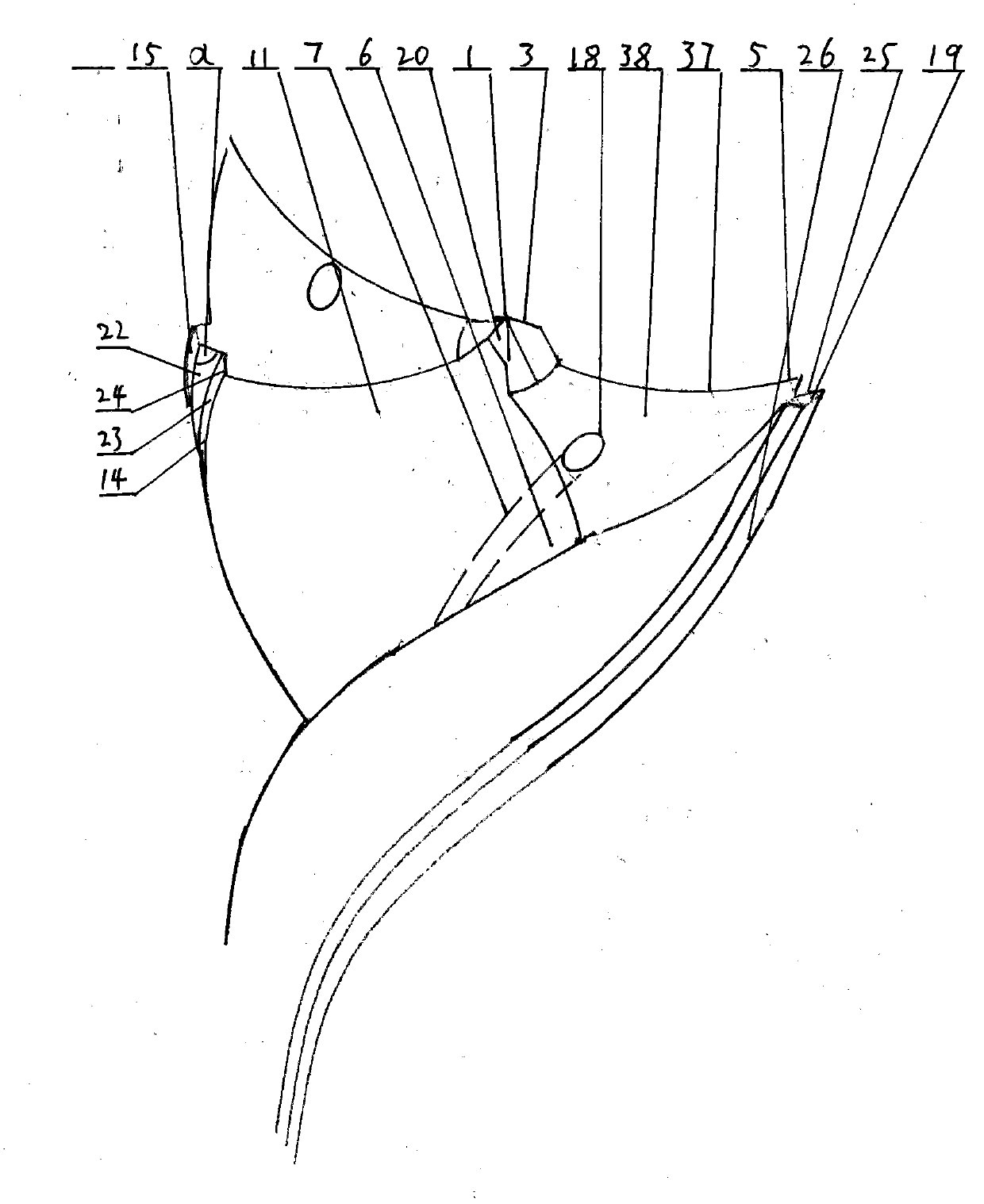

[0039] Such as figure 2 , Figure 7-Figure 10 , Figure 11-Figure 14 As shown in Embodiment 2, the self-cooling technology and processing method of the sheet metal spiral stepped edge twist drill of the second embodiment of the present invention and its processing method, on the basis of the first embodiment, the secondary cutting edge 37 of the present invention mainly functions To stabilize the cutting, the secondary cutting edge 37 and the main cutting edge 5 form an arc-shaped secondary cutting edge 37, that is, an arc-shaped edge or a curved edge, and extend to the rear cutting surface 4 to form a structure with an arc-shaped groove or groove , the angle between the main cutting edge 5 and the helical minor cutting edge 14 is less than 90°.

[0040] By setting the arc-shaped groove or groove on the rear cutting surface 4, the cutting stability and efficiency of the twist drill are improved, the cost is reduced, and resources are saved.

[0041] According to the above ...

Embodiment approach 3

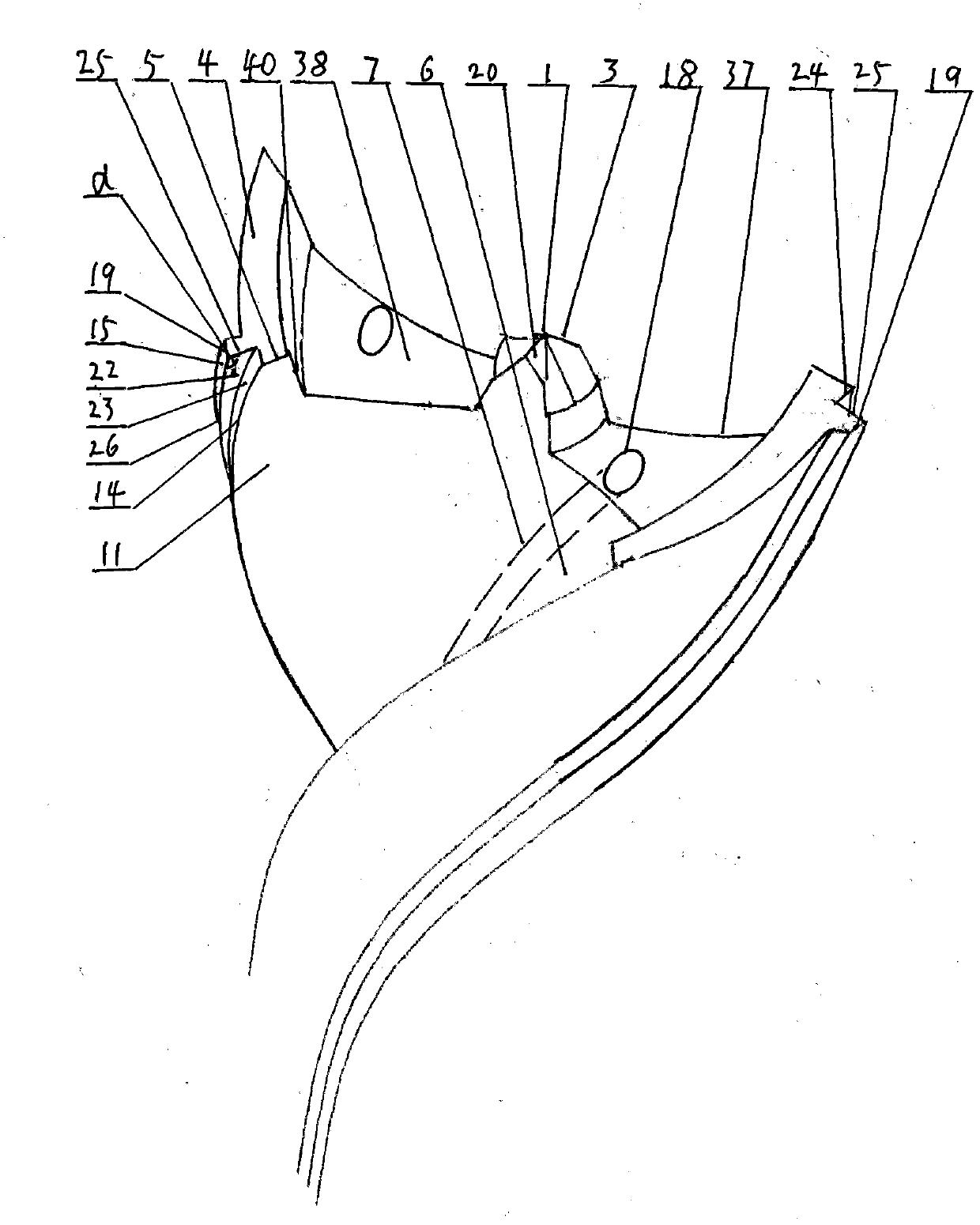

[0043] Such as image 3 , Figure 7-Figure 10 , Figure 11-Figure 14 As shown, the self-cooling technology and processing method of the sheet metal spiral stepped edge twist drill of the third embodiment of the present invention, on the basis of the first and second embodiments, the minor cutting edge 37 of the present invention mainly plays a role in stabilizing cutting The minor cutting edge 37 and the major cutting edge 5 form an arc-shaped minor cutting edge 37, that is, a trapezoidal edge, and extend to the rear cutting surface 4 to form a trapezoidal groove structure. The major cutting edge 5 and the helical minor cutting edge 14 The included angle is greater than 90°.

[0044] The cutting efficiency of the main cutting edge 5 is ensured by the included angle between the main cutting edge 5 and the helical minor cutting edge 14 being greater than 90°, and the setting of the trapezoidal groove 38 on the minor cutting edge 37 effectively prevents cutting obstruction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com