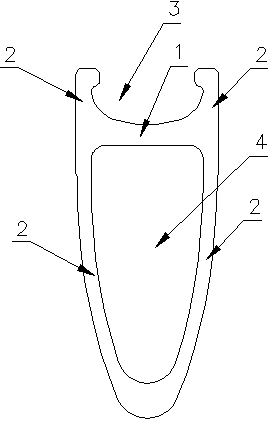

Multi-TG (glass transition temperature) carbon fiber wheel rim as well as manufacturing method thereof

A technology of carbon fiber and carbon fiber materials, applied to wheels, rims, wheels made of non-metallic materials, etc., can solve the problems of low impact resistance, low output, and restrictions on large-scale promotion, achieve good rigidity and toughness, and improve impact resistance strength and reduce the risk of burning the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

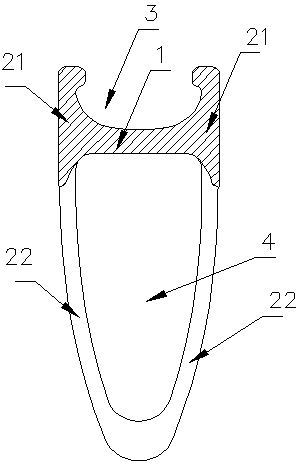

Embodiment 1

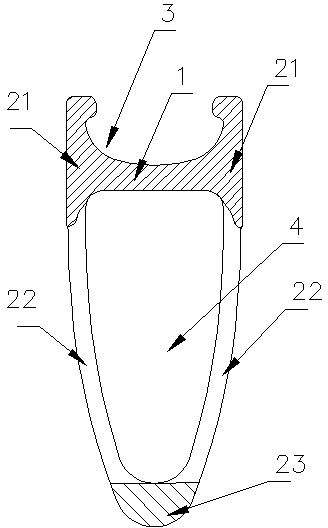

[0040] Embodiment two

Embodiment 2

[0042] The preparation method of embodiment one, comprises the following steps:

[0043] Step 1. Forming of "H"-shaped structure carbon ring: Make a forming mold 5 of "H"-shaped groove, and lay carbon fiber resin prepreg cloth with a TG range of 190°C to 220°C in the "H"-shaped groove of the mold 53, lock the mold and put it into a high-temperature oven for molding. The molding temperature in the oven is 200°C, and the heating time is 6 hours, or the molding temperature in the oven is 220°C, and the heating time is 4 hours; then demould and set aside ;

[0044] Step 2, "V" shaped inner cavity carbon ring molding: as Figure 6 As shown, the carbon fiber resin prepreg with a TG range of 100°C to 180°C is laminated according to the shape of the inner cavity of the rim to form a "V"-shaped inner cavity carbon ring, and the V-shaped inner cavity carbon ring At the opening of the ring, there is reserved a carbon fiber prepreg sheet combined with the "H"-shaped carbon ring, which a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com