A self-lubricating cable guide wheel

A technology of guide wheels and steel cables, applied in elevators, transportation and packaging, etc., can solve safety hazards, inconvenience and other problems, and achieve the effects of prolonging the use time, facilitating cleaning and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a further explanation in conjunction with the drawings:

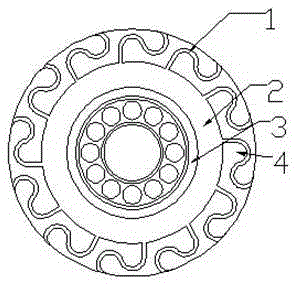

[0020] A self-lubricating steel cable guide wheel. The guide wheel includes a rolling outer frame for pulling the steel cable and a rotating shaft installation hole 3 arranged in the middle of the guide wheel. The guide wheel also includes an oil storage cavity 2 and an oil leakage groove 1 The oil storage cavity 2 is provided between the rolling outer frame and the rotating shaft mounting hole 3, and the oil seepage groove 1 is a groove-like gap provided inside the rolling outer frame for communicating the oil storage groove and the outer wall of the rolling outer frame, The number of the oil seepage grooves 1 is 12, and the oil seepage grooves are arranged in an annular array relative to the center of the guide wheel.

[0021] The oil permeation path of the groove-shaped gap of the oil seepage groove 1 is S-shaped, one of the arcs 4 of the S shape refers to the center of the guide wheel, and the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com