Method for rapid mutagenesis of autotrophic nitrosation sludge from complete nitrifying sludge

A technology of nitrifying sludge and full nitrification, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the secondary pollution of the environment, consume a lot of energy, and the cost of sewage treatment is high No inferior problems, to achieve simple operation, stable nitrosation process, easy to control the effect

Active Publication Date: 2014-04-16

BEIJING UNIV OF TECH

View PDF4 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, for urban domestic sewage with a low carbon-to-nitrogen ratio, most sewage treatment plants adopt the traditional process based on the principle of nitrification and denitrification for biological denitrification. In order to meet the requirements of denitrification, it is necessary to add an organic carbon source, which consumes a huge amoun

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

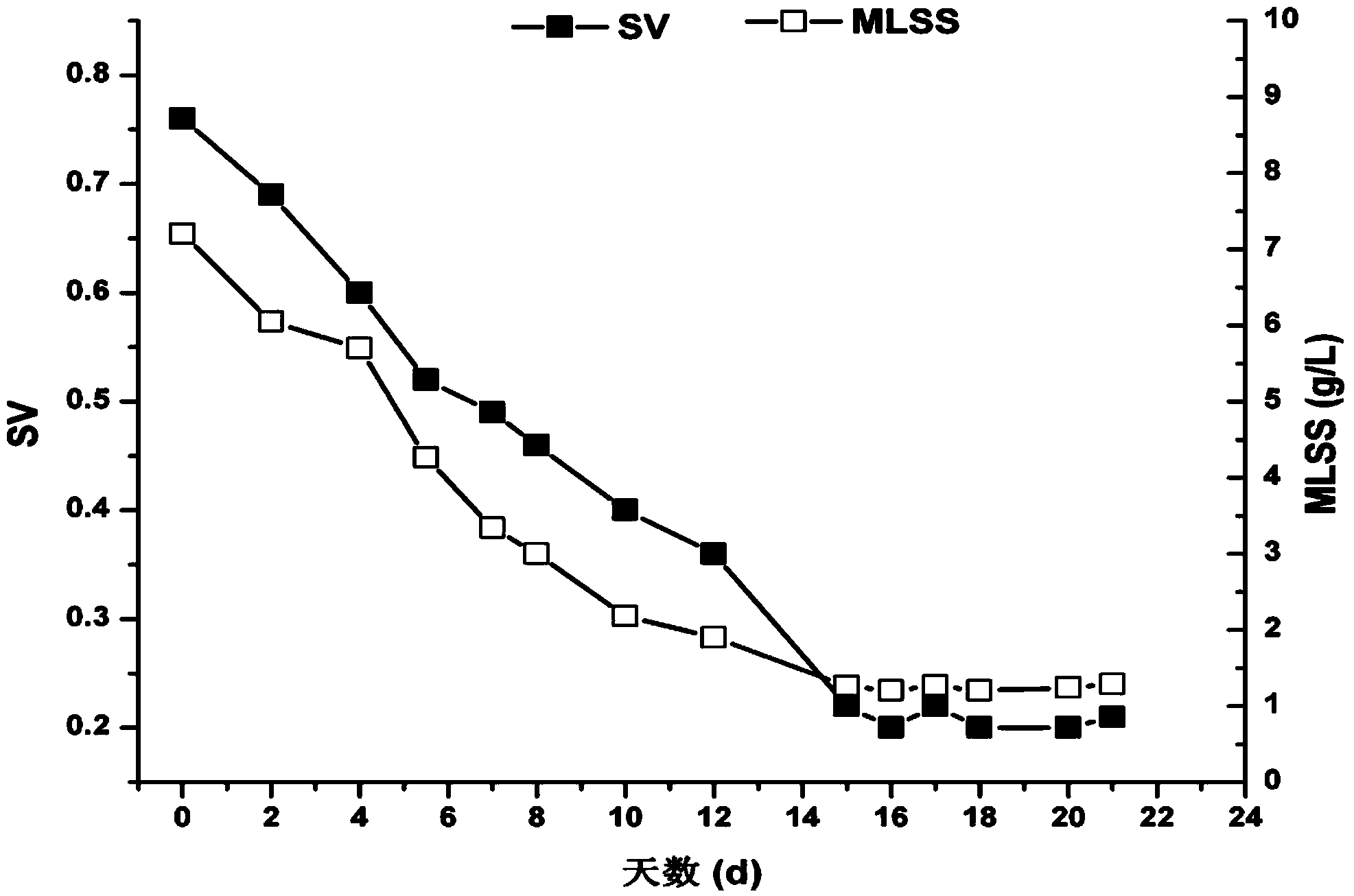

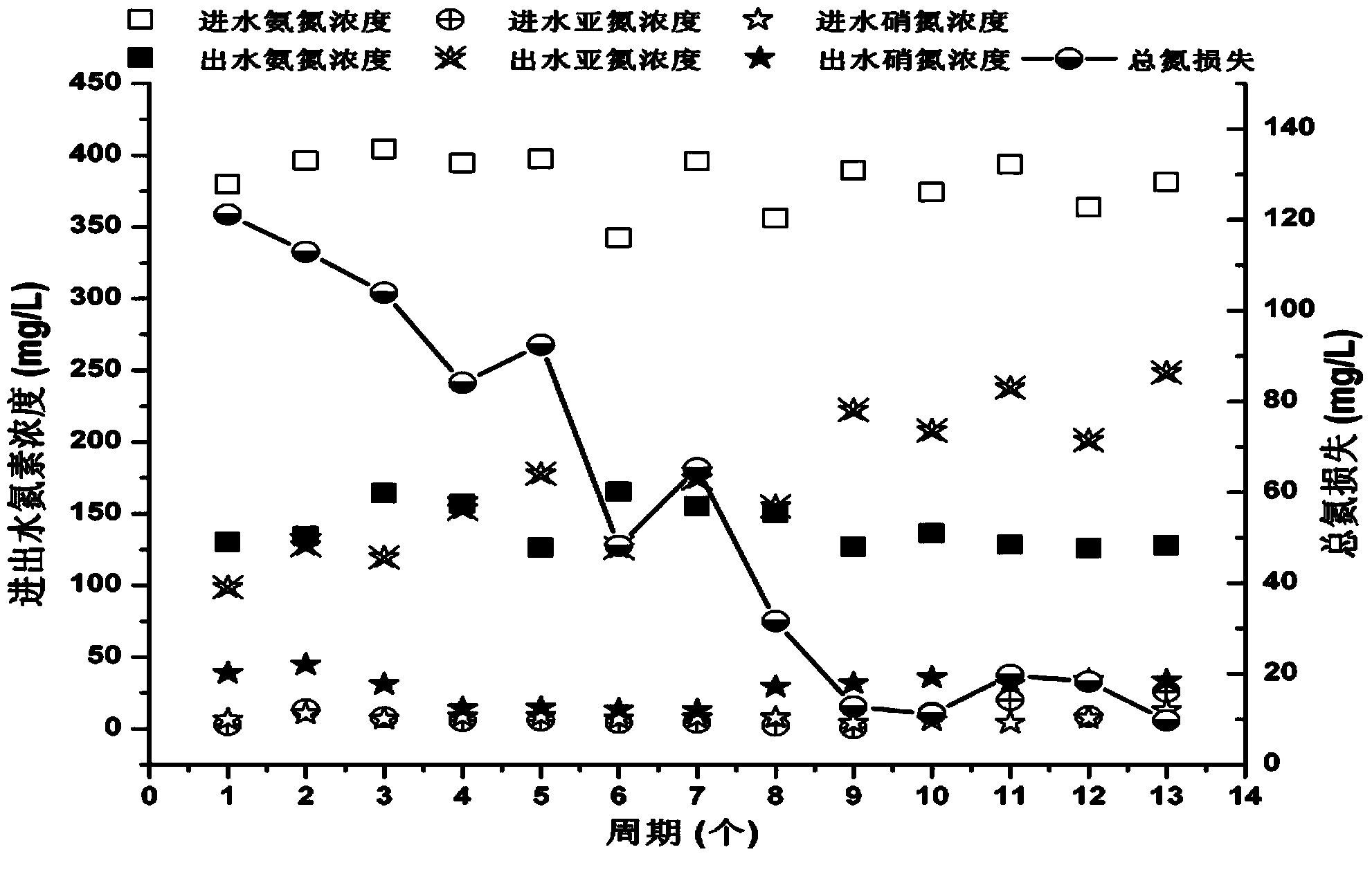

[0027] The present invention is a method for rapidly mutagenizing whole-process nitrification sludge into autotrophic nitrosation sludge. The idea is: inhibit sludge expansion, adapt to SBR reactor—eliminate heterotrophic microorganisms—purify semi-nitrosative sludge to cultivate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for rapid mutagenesis of autotrophic nitrosation sludge from complete nitrifying sludge employing a sequencing batch reactor (SBR) mode, and belongs to the fields of water environment restoration and regeneration and the field of autotrophic nitrogen removal of a sewage treatment plant. The method comprises the following steps: firstly, inoculating nitrifying sludge of a sewage plant; controlling high ammonia-nitrogen concentration, high free ammonia and high aeration condition to prevent sludge from bulking, so as to rapidly adapt to an SBR reactor; then gradually eliminating heterotrophic microorganisms under the water condition with high ammonia-nitrogen and absence of an organic carbon source; finally, inhibiting growth of autotrophic bacteria such as nitrite oxidizing bacteria (NOB) under the condition of low dissolved oxygen; purifying nitrosation sludge, so as to successfully achieve transformation from heterotrophic nitrification sludge to autotrophic nitrosation sludge. By adopting the method, the heterotrophic bacteria are eliminated, and the autotrophic nitrosification technology is developed. Compared with the traditional nitrogen removal process, the method is small in oxygen demand, low in energy consumption and free of a lot of organic carbon sources.

Description

technical field [0001] The invention belongs to the field of water environment restoration and regeneration and the field of autotrophic denitrification of sewage treatment plants. Specifically, it relates to a method specially used for normal temperature, SBR mode operation, and rapid mutagenesis of whole-process nitrification sludge into nitrosation sludge. Background technique [0002] Since the Eleventh Five-Year Plan, the state has stepped up efforts to control environmental pollution, especially in the restoration of the water environment, and implemented a major national science and technology project - Water Pollution Control and Treatment, with an investment of 11.266 billion yuan. This figure will further increase to more than 14 billion yuan. This move is to solve the problem of water eutrophication caused by excessive discharge of nitrogen and phosphorus in recent years. According to the 2012 Environmental Status Bulletin, the surface water in the country is ge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/12

CPCY02W10/10

Inventor 李冬吴青苏庆岭梁瑜海曾辉平张杰

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com