Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "The scope of protection is not limited" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

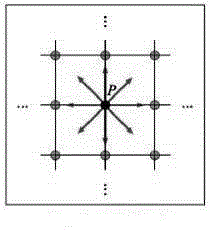

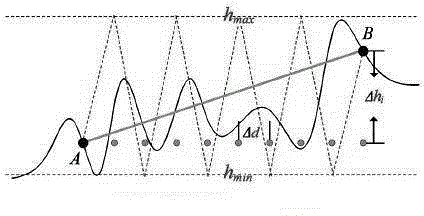

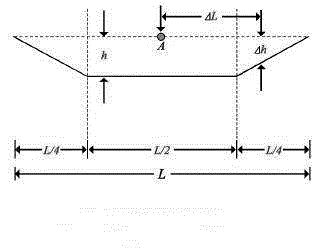

Unmanned plane airline routing algorithm based on improved A* algorithm

InactiveCN104075717AImprove computing efficiencyMeet planning requirementsNavigational calculation instrumentsForecastingAlgorithmThree-dimensional space

The invention relates to an airline routing algorithm of an unmanned plane in a large-range complicated three-dimensional space. The algorithm comprises the following steps: first dividing a three-dimensional space on the basis of a 2.5-dimensional grid (each grid point includes longitude, altitude and elevation information); improving the A* cost function by comprehensively considering the influence factors such as airline height, detected probability, airline distance under the constraint conditions of radar, disaster weather and forbidden areas, and determining an initial airline on the basis of an algorithm search flow; serially processing the initial airline to obtain a final flying airline for meeting the performance constraint of the unmanned plane (such as minimal step length, turning radius, climbing rate, safety height). The algorithm is good in stability and astringency, high in efficiency, capable of meeting the wide-range low-altitude airline routing requirement and applicable to relevant fields such as military, national defense, emergency relief.

Owner:WUHAN JI JIA WEI YE TECH DEV CO LTD

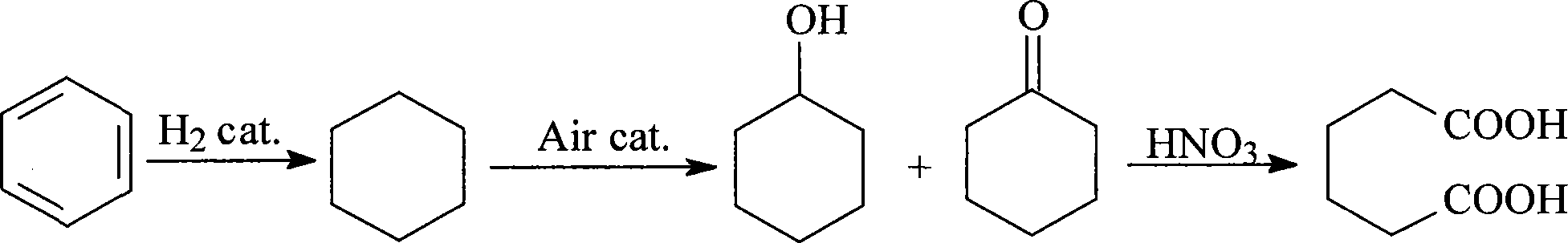

Method for preparing adipic acid by using cyclohexane catalytic oxidation one-step method

InactiveCN101239899ALow reaction temperatureReduce pressureOrganic compound preparationChemical recyclingCatalytic oxidationAdipic acid

The invention discloses a method for preparing adipic acid by one step of catalysis and oxidation of cyclohexane. The method comprises: firstly adding cyclohexane, a solvent, an initiator and a solid catalyst into a reactor to mix, forming a mixing suspension; rising the temperature of the formed mixing suspension to 50-250 DEG C, insufflating abundant oxygen or air as the oxidant, setting the pressure of the reactor is 0.1-5 MPa, the reaction time is 0.1-20h; separating the reaction mixture to obtain the solid catalyst, and a liquid mixture contained reacted products, un-reacted products and the solvent; and finally separating adipic acid from the separated liquid phase mixture. The invention avoids environmental pollution due to use of nitric acid, and device corrosion; solves the problem that the homogeneous catalyst is difficult to recovery during cyclohexane oxidation; has high reaction selectivity and good activity. The catalyst used in the invention can be recoveried and recycled.

Owner:SOUTH CHINA UNIV OF TECH

Method for repeatedly extracting natural hirudin from live vampire leech

ActiveCN102964446ANon-toxic ingredientsNot corrosiveLeech-based protease inhibitorsBiotechnologyBiochemical engineering

The invention provides a method for repeatedly extracting natural hirudin from live vampire leech. The method comprises the steps of: firstly extracting crude natural hirudin from the live vampire leech, then carrying out separation and purification to obtain natural hirudin, wherein the extraction of the crude natural hirudin comprises the steps of: firstly preparing specific induction liquid and then pouring into intestinal canal to obtain specific induction liquid-containing intestinal canal; then feeding the specific inducing liquid-containing intestinal canal to the vampire leech, and extracting the spit of the vampire leech or grinding the vampire leech into slurry, thereby obtaining the crude natural hirudin; and the crude natural hirudin is separated and purified to obtain natural hirudin powder according to a conventional biochemical separation method. The method is simple in process, and high in extraction rate, the death rate of the vampire leeches can be obviously reduced after the crude natural hirudin is extracted, and biological resource utilization rate can be effectively improved, so that the production cost can be obviously lowered; therefore, the method is a convenient approach for extracting the main effective active substance (such as natural hirudin) from the leech body.

Owner:周维官

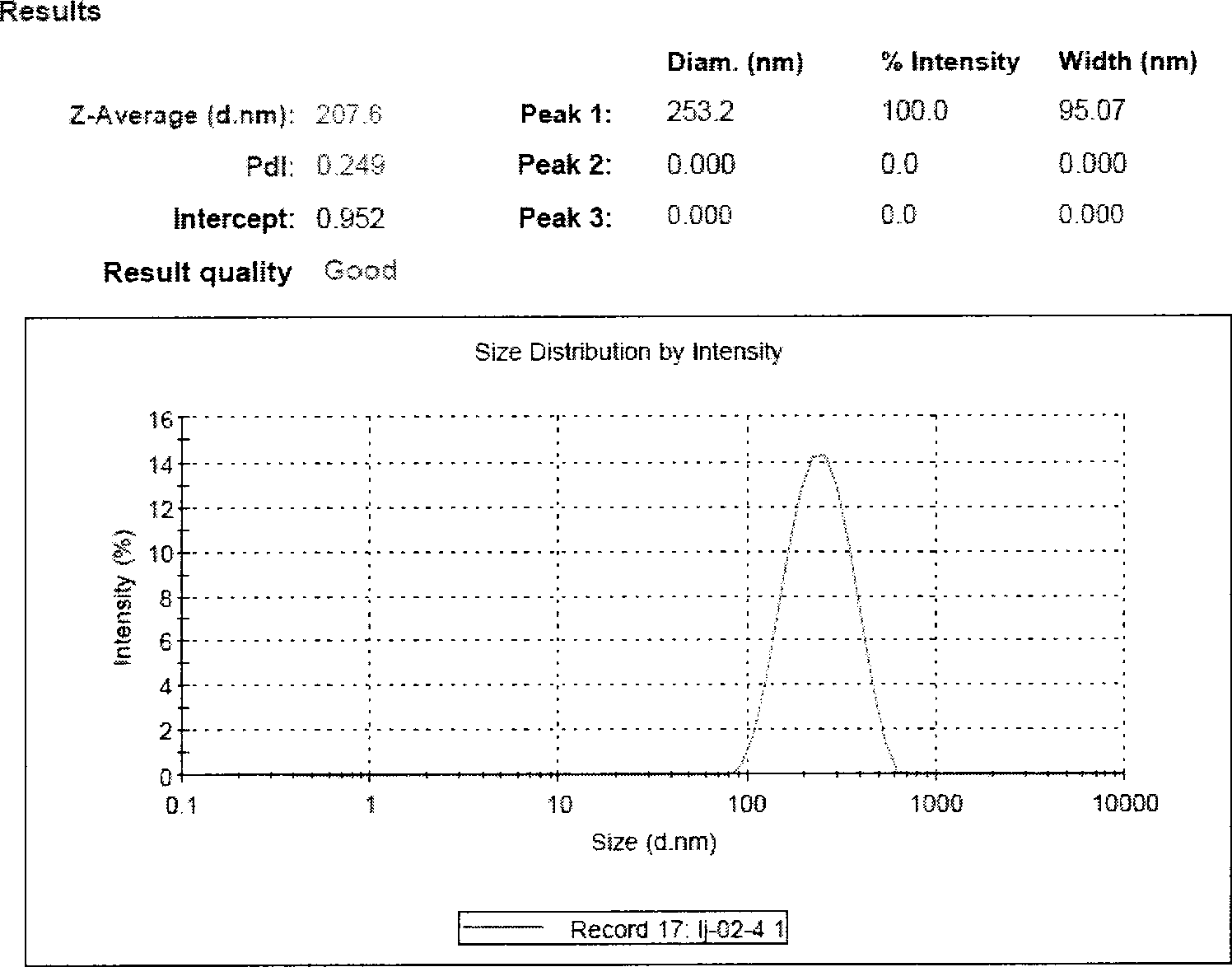

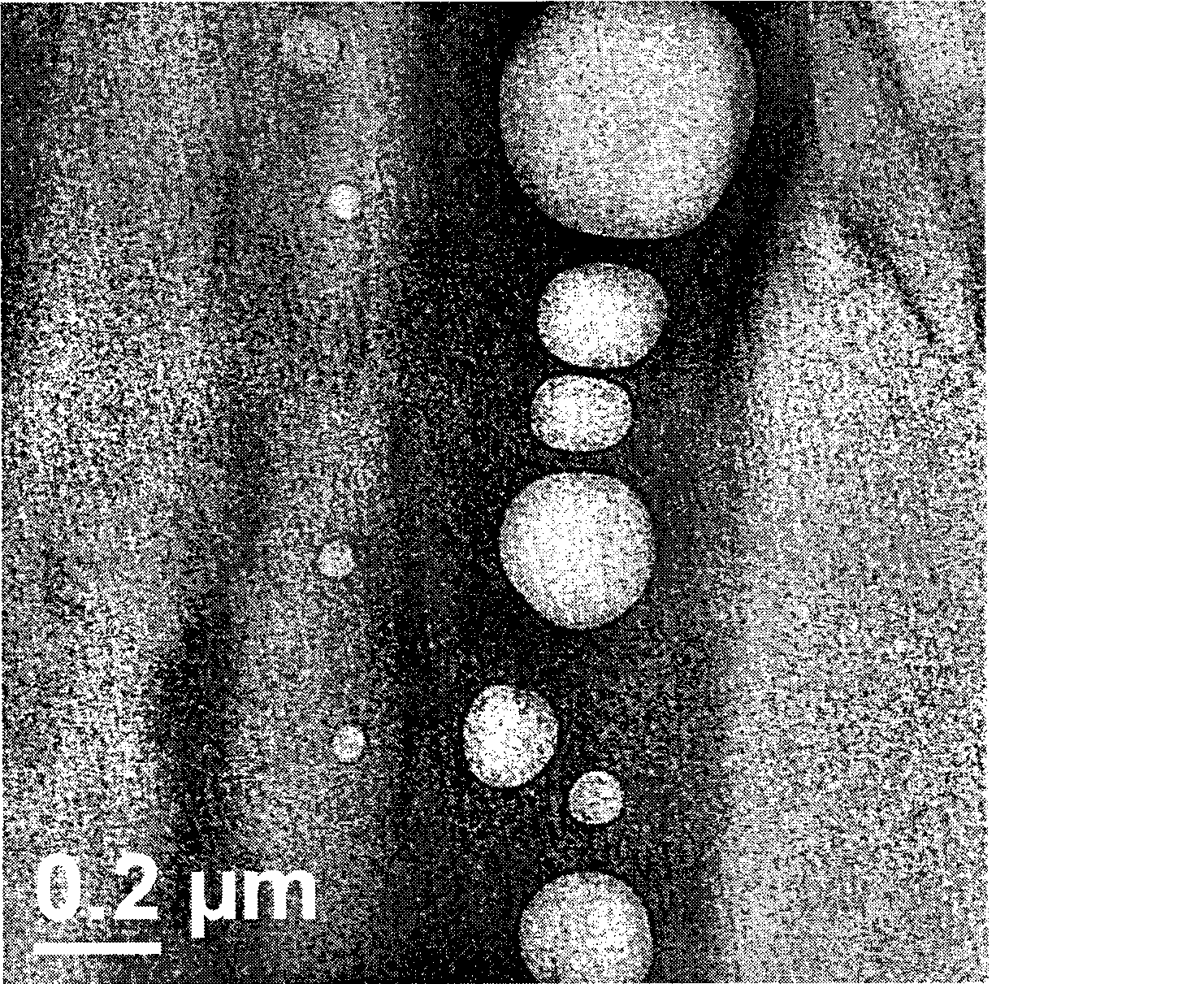

Preparation method of novel hard-soluble medicine liposome

InactiveCN101385715AWell mixedSimple production processPharmaceutical non-active ingredientsLiposomal deliveryOrganic solventDiluent

The invention provides a preparation method of a novel insoluble drug liposome without the application of an organic solvent in the preparation process. The invention names the method as a water soluble surfactant dispersion method. The preparation method comprises the following steps: A. an insoluble drug is dissolved or suspended or mixed in a water soluble surfactant; B. lipid substances, a water soluble diluent and the water soluble surfactant which is dissolved or suspended or mixed with the insoluble drug for forming the liposome are evenly mixed; C. the appropriate amount of water or water solution is added in the mixture which is obtained in step B, the even mixing is carried out, and the high pressure homogenization or the high pressure homogenization is carried out, thereby obtaining liposome suspension; D. other liposome components can be added by adopting the appropriate method in any step of the steps of A, B and C according to the physical and the chemical properties, if the insoluble drug liposome does not contain other liposome components, the liposome components can not be added.

Owner:CHINA PHARM UNIV

Preparation method of unidirectional carbon/carbon composite material with high heat conductivity

The invention discloses a preparation method of a unidirectional carbon / carbon composite material with high heat conductivity. The preparation method comprises the following steps: preparing a pitch dispersion liquid from mesophase pitch; evenly applying the pitch dispersion liquid onto the surfaces of fixed-length mesophase-pitch-based carbon fibers, or soaking continuous mesophase-pitch-based carbon fibers in the pitch dispersion liquid; naturally airing or drying the fibers to obtain a one-dimensional carbon-carbon composite material preform; performing compression molding on the one-dimensional preform, i.e., performing hot compression molding and once soaking for pitch densification; and then performing hot repressing for graphitization. The preparation method has the advantages of simple preparation technology, easily-controlled operation parameters, good repeatability and short production cycle, large-sized products can be obtained, and the method is suitable for large-scaled production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

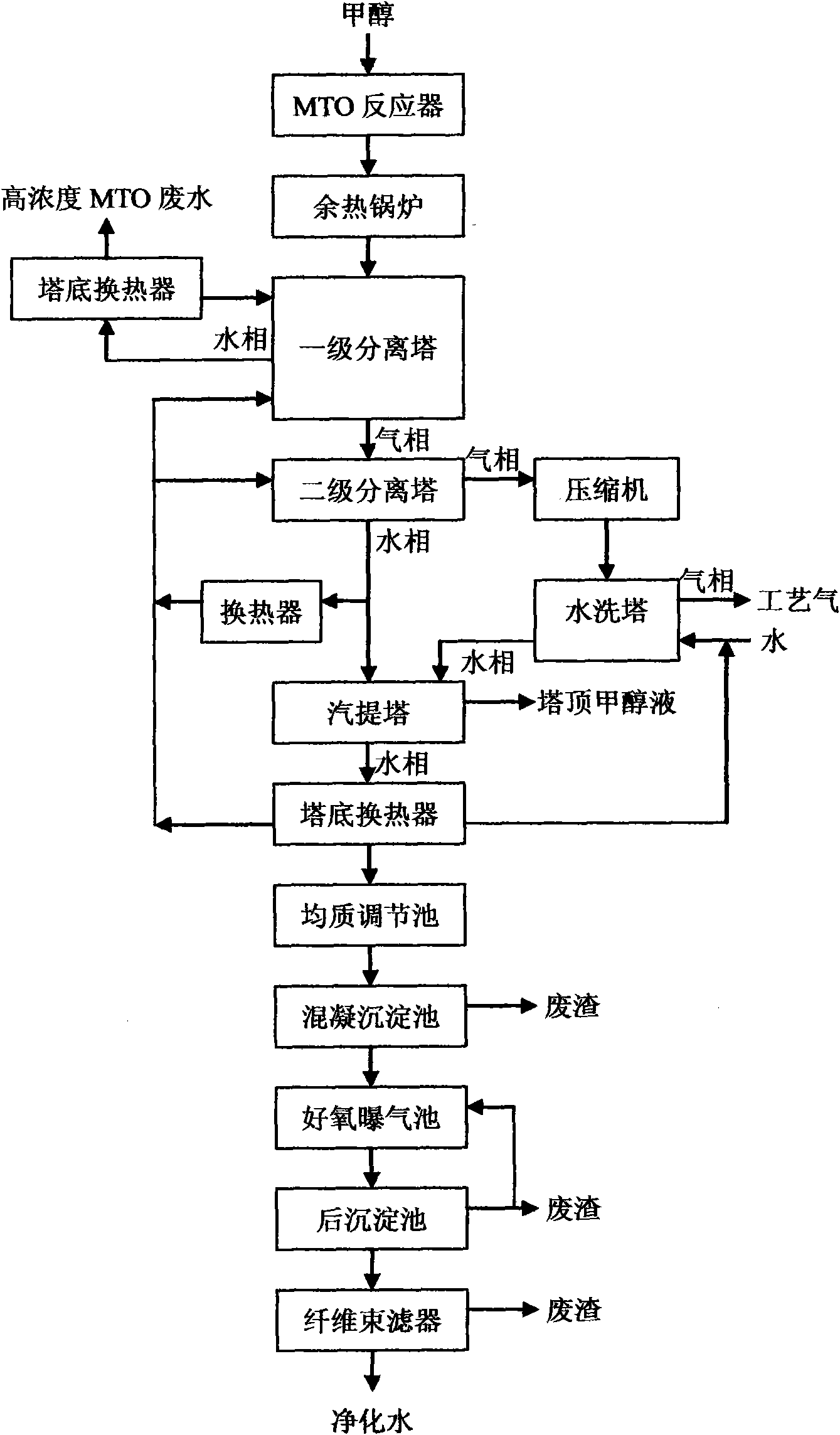

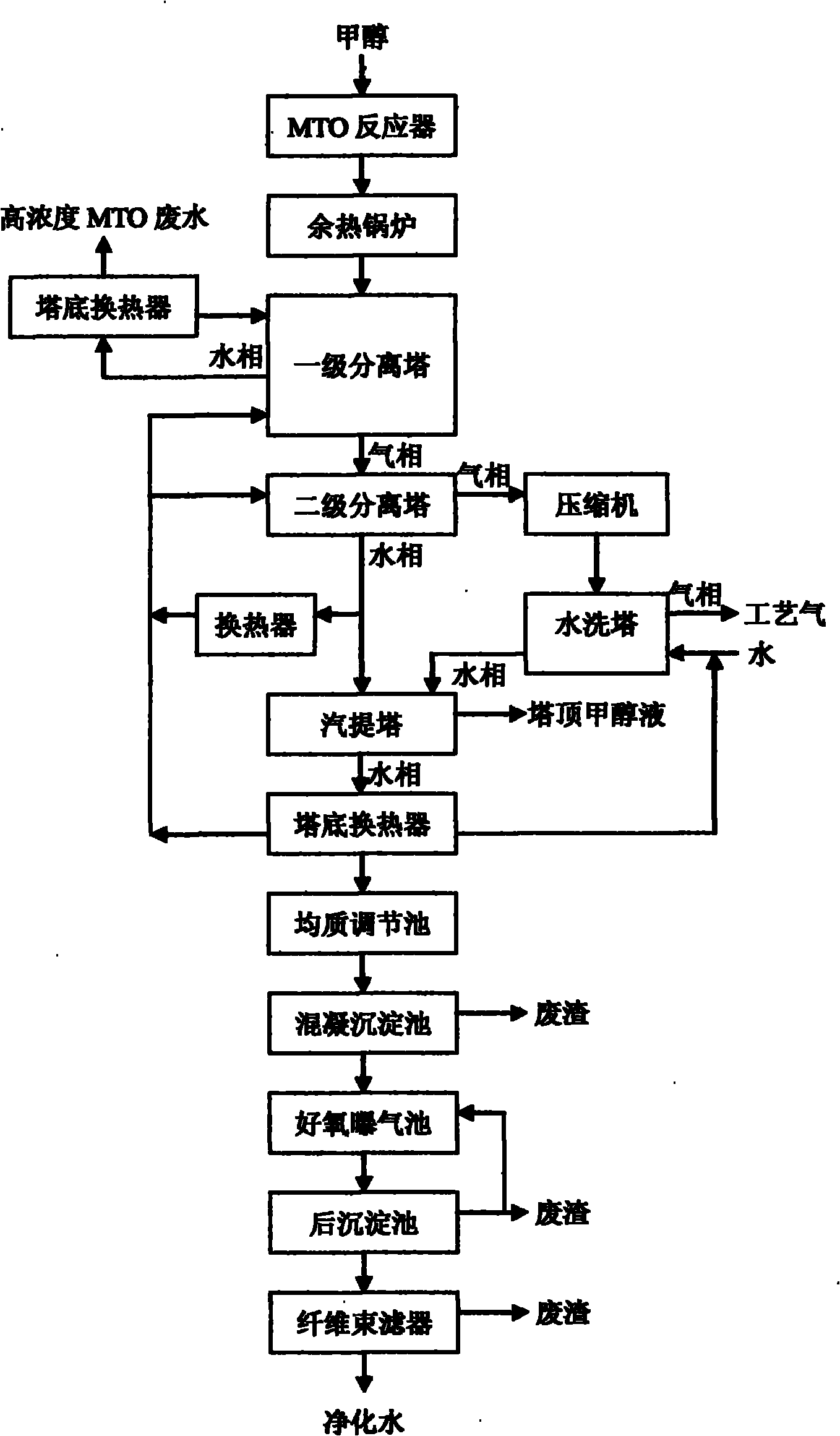

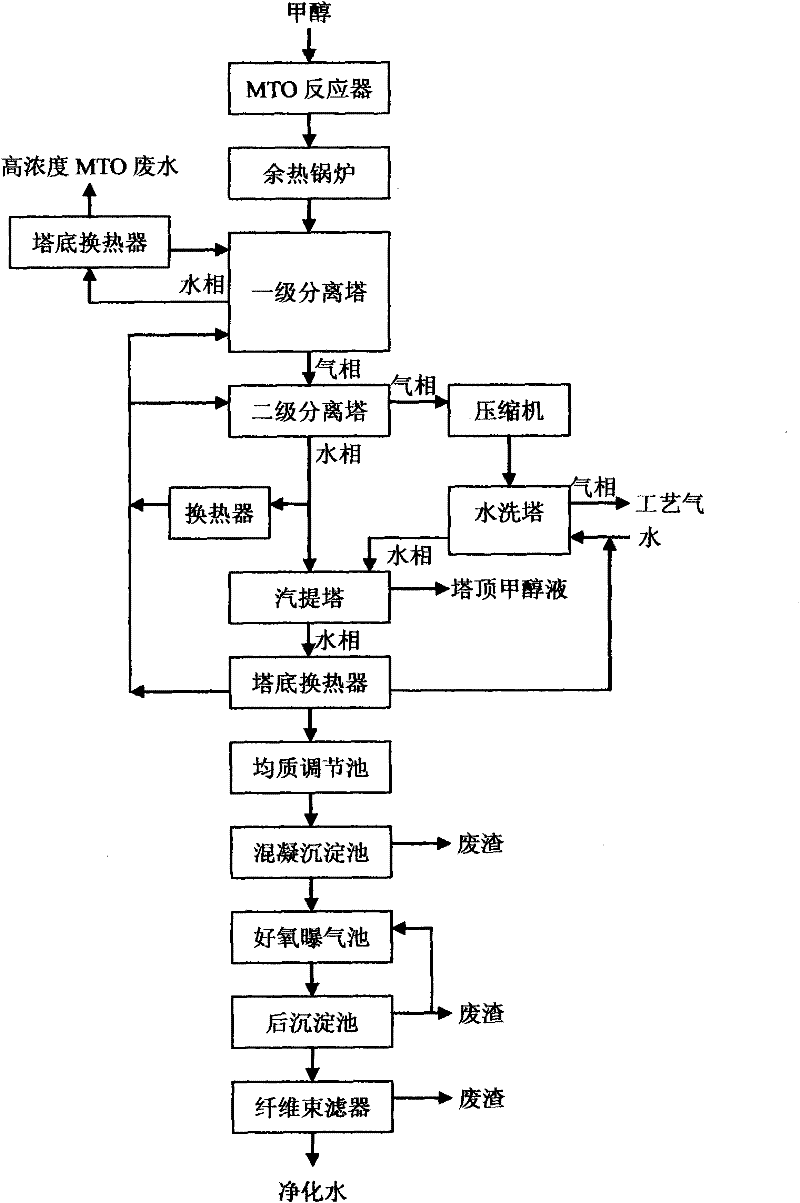

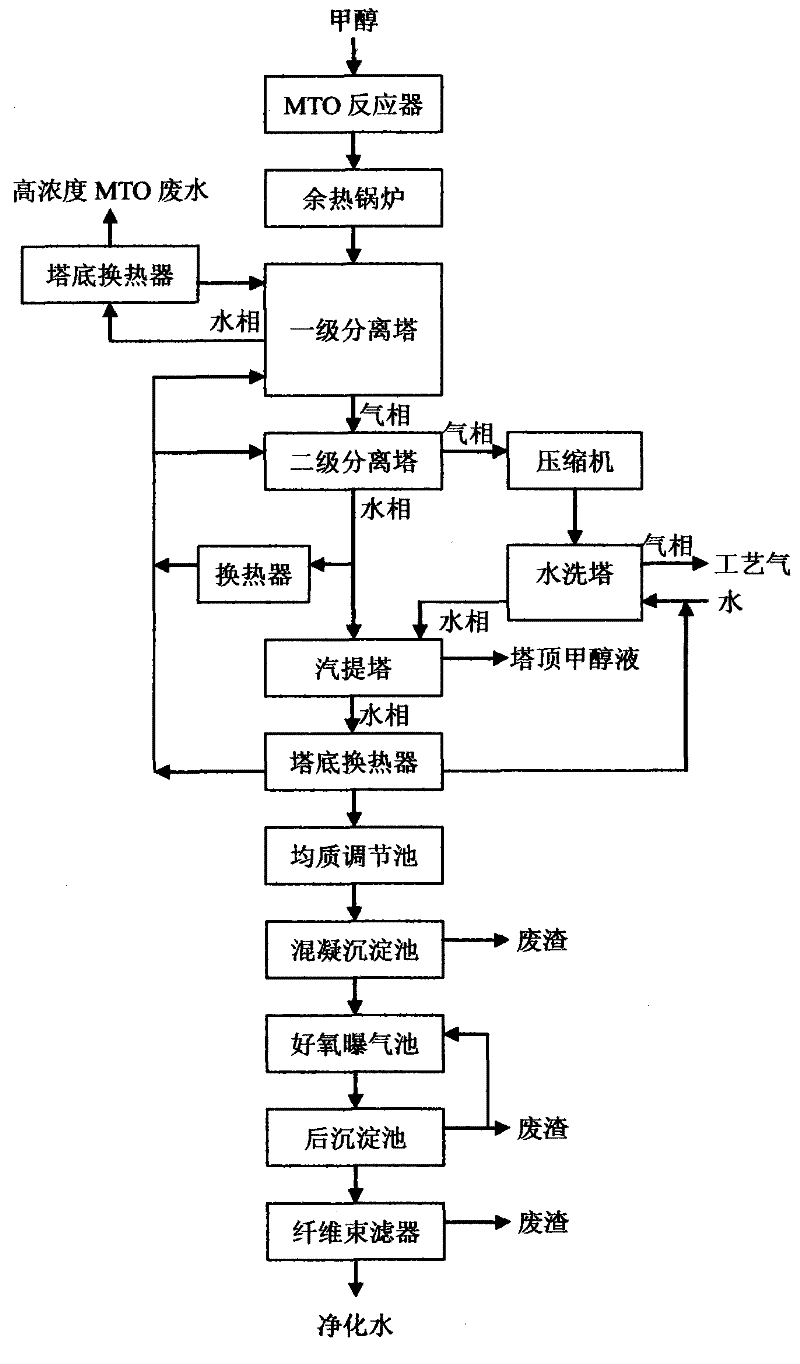

Treatment and reuse method of waste water in methanol-to-olefin process

ActiveCN102050548AEfficient use ofReduce dosageChemical industryHydrocarbon from oxygen organic compoundsHigh concentrationFiltration

The invention relates to a treatment and reuse method of waste water in a methanol-to-olefin (MTO) process. The method comprises the following steps: (1) an effluent from an MTO reactor is subjected to the waste heat recovery through a waste heat boiler and then cooled and separated through a separation tower to generate high concentration MTO waste water; (2) the effluent from the MTO reactor is further cooled, a water phase is generated at the bottom of the separation tower, an olefin gas is generated at the top of the separation tower, and the olefin gas is further purified by compression and water scrubbing; (3) the water phase from the bottom of the separation tower and a water phase from bottom of a water scrubbing tower are treated by steam stripping, and a water phase generated at the bottom of a steam stripping tower is cooled through a tower bottom heat exchanger to generate low concentration MTO water; (4) the low concentration MTO water is homogenized; (5) the low concentration MTO water is subjected to the coagulating sedimentation treatment after the homogenization; (6) the low concentration MTO water is subjected to the aerobic aeration treatment after the coagulating sedimentation treatment; (7) the effluent water is settled after the aerobic aeration treatment; and (8) the effluent water is subjected to the flocculation filtration treatment after the settlement. The method can not only reduce the consumption of the fresh water in the MTO production, but also reduce the discharge of pollutants to the environment in the MTO production.

Owner:CHINA PETROLEUM & CHEM CORP +1

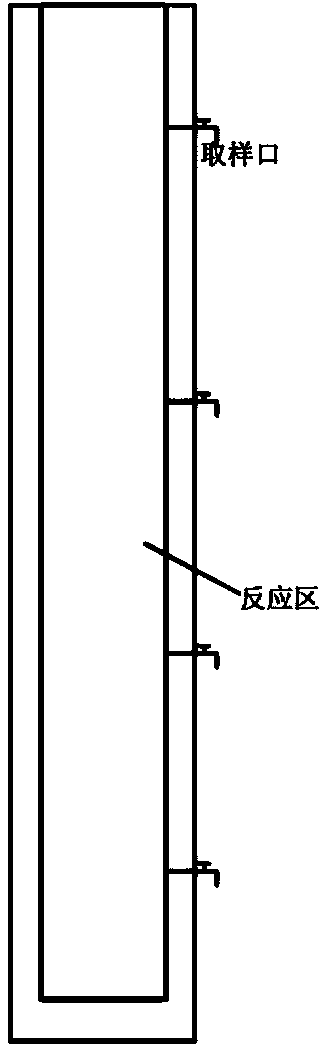

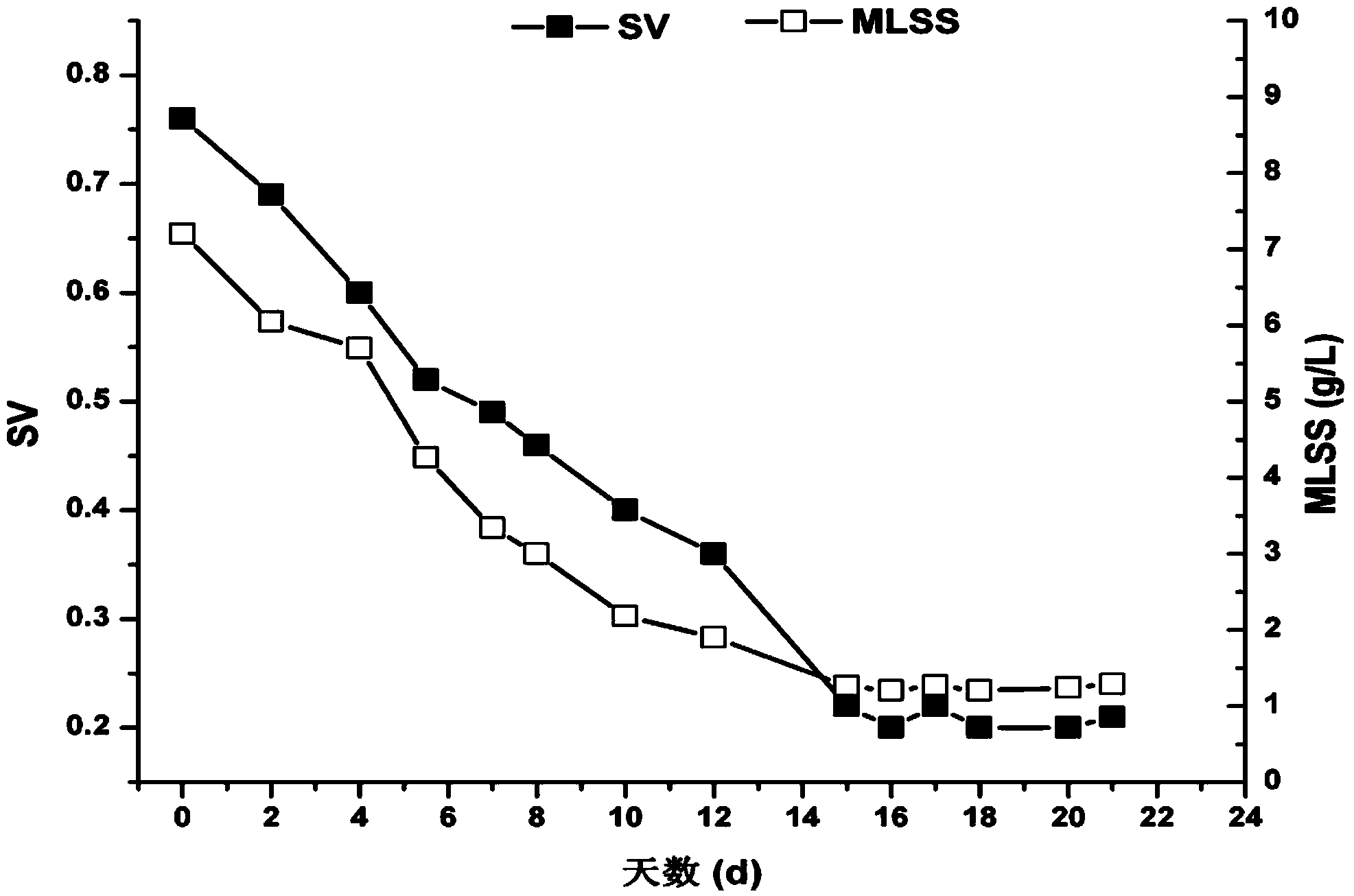

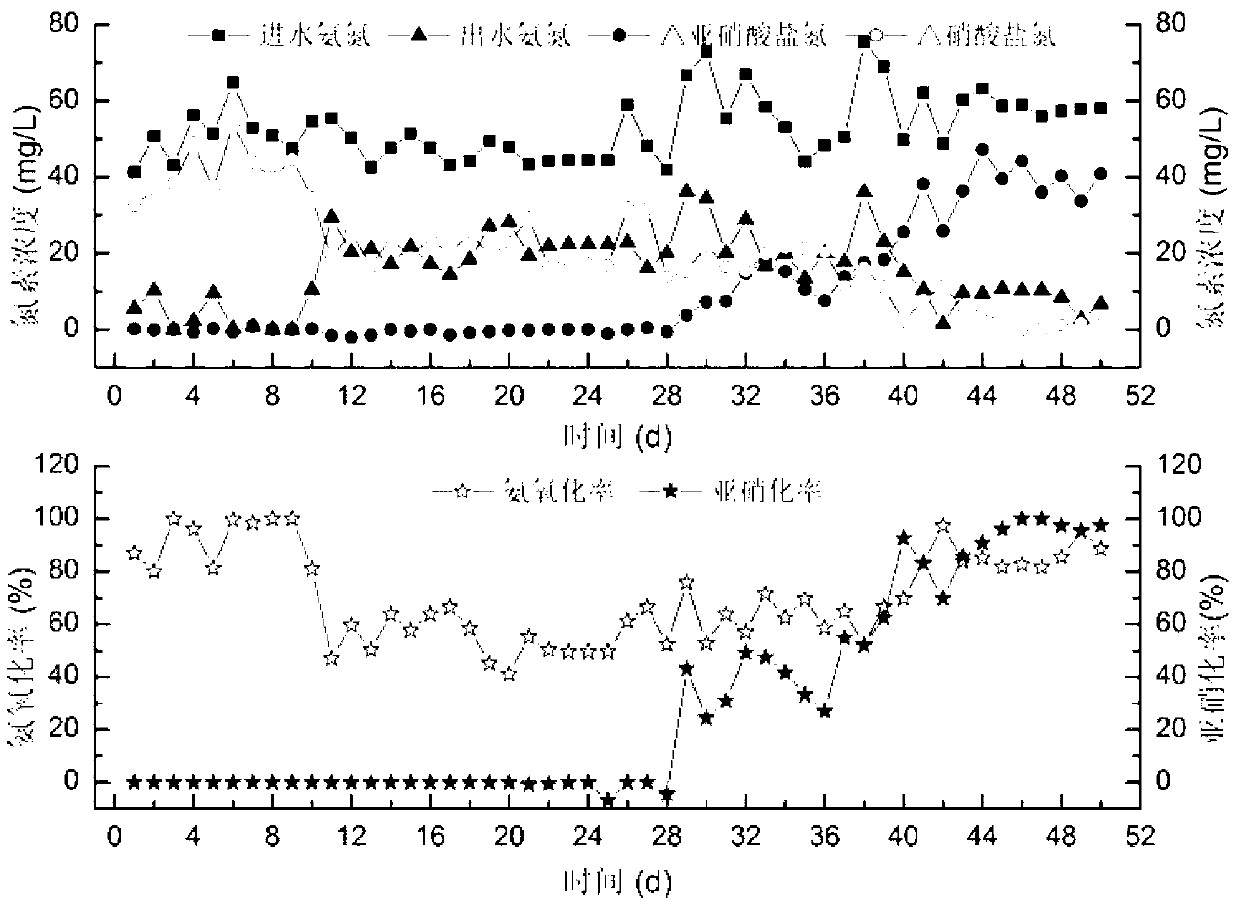

Method for rapid mutagenesis of autotrophic nitrosation sludge from complete nitrifying sludge

ActiveCN103723821AInhibit swellingAchieve nitrosationSustainable biological treatmentBiological water/sewage treatmentLow dissolved oxygenMutagenic Process

Owner:BEIJING UNIV OF TECH

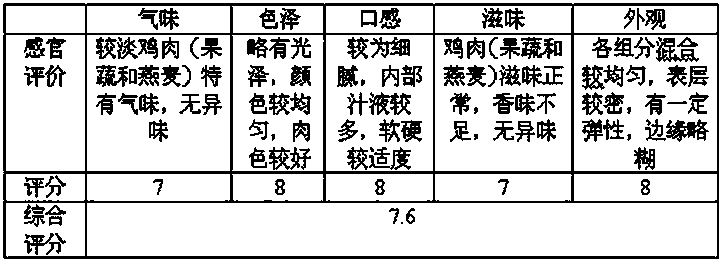

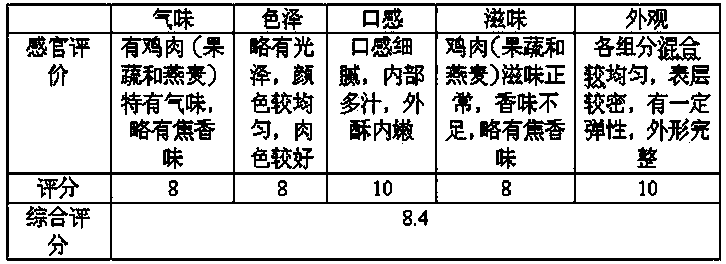

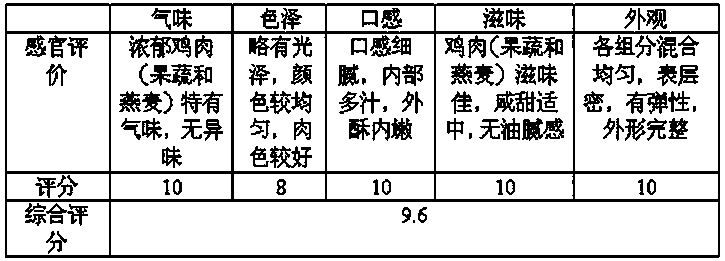

Chicken jerky and preparation method thereof

InactiveCN103462064ASoft textureChange the characteristics without dietary fiberFood preparationFruit juiceAdditive ingredient

The invention discloses chicken jerky and a preparation method thereof, belonging to the field of a food processing technology. By taking chicken, fruit and vegetable dregs and oats as main raw materials, the preparation method comprises the following steps of freezing and preserving the raw materials in a freezing chamber firstly, baking and roasting, and then spraying fruit juice on the surface of a semi-finished product to obtain the product. The preparation method is simple and convenient to operate, can fully keep the nutritional ingredients of chicken, effectively combine the nutritional ingredients of the fruits and vegetables and the oats, and can effectively prevent the nutritional ingredients and active ingredients from loss and destruction by adopting a special baking process; furthermore, the chicken jerky forms a special fruit, vegetable and chicken compound flavor, has good mouthfeel and smooth and seamless appearance, can be eaten instantly, and can be used as snack foods such as small snacks, or used as geriatric foods with low fat and low calorie.

Owner:KUNMING UNIV OF SCI & TECH

Polypeptide nutritional health-care food containing marine fish oligopeptides

The invention discloses a polypeptide nutritional health-care food containing marine fish oligopeptides. The food comprises the following raw materials in percentage by weight: 20 to 35 percent of marine fish oligopeptide powder, 10 to 25 percent of soy peptide powder, 10 to 25 percent of spirulina, 10 to 15 percent of soy isolate protein, 10 to 15 percent of soyabean lecithin, 5 to 10 percent ofblack fungus powder, 5 to 10 percent of fructo-oligosaccharide, 2 to 5 percent of microcrystalline cellulose, and 1 to 3 percent of magnesium stearate. The product has wide application range, is suitable for patients with high blood sugar or diabetes mellitus, can be easily absorbed by a human body, has the effects of preventing diseases and beautifying besides high nutritional value, is advantageous to removing waste generated in the body in time and enriching the variety of polypeptide foods home and abroad.

Owner:邹军

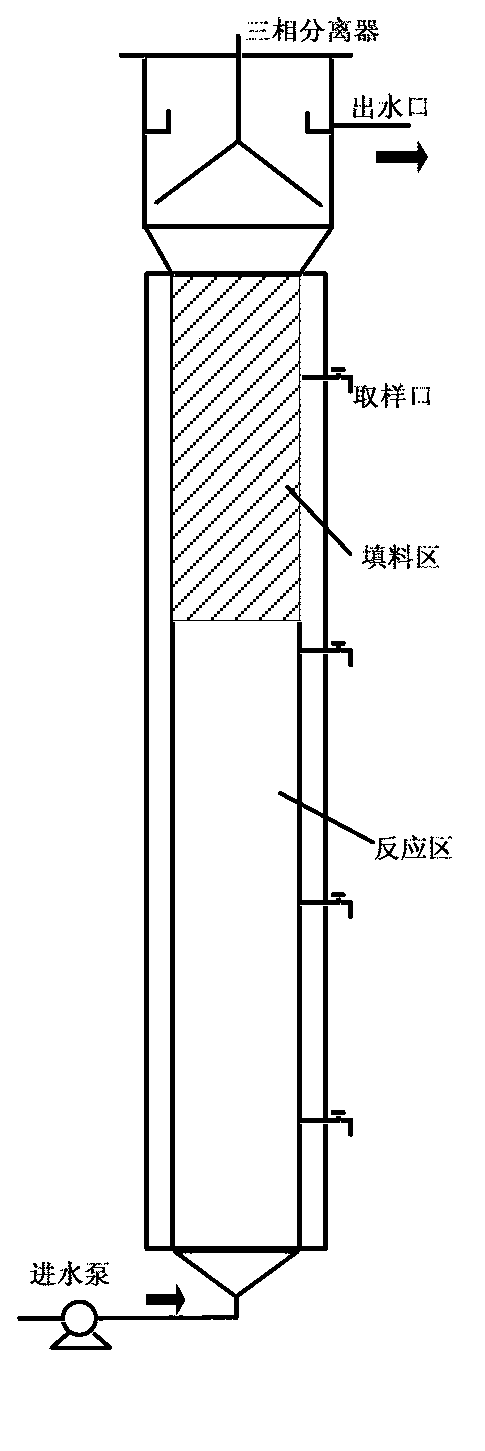

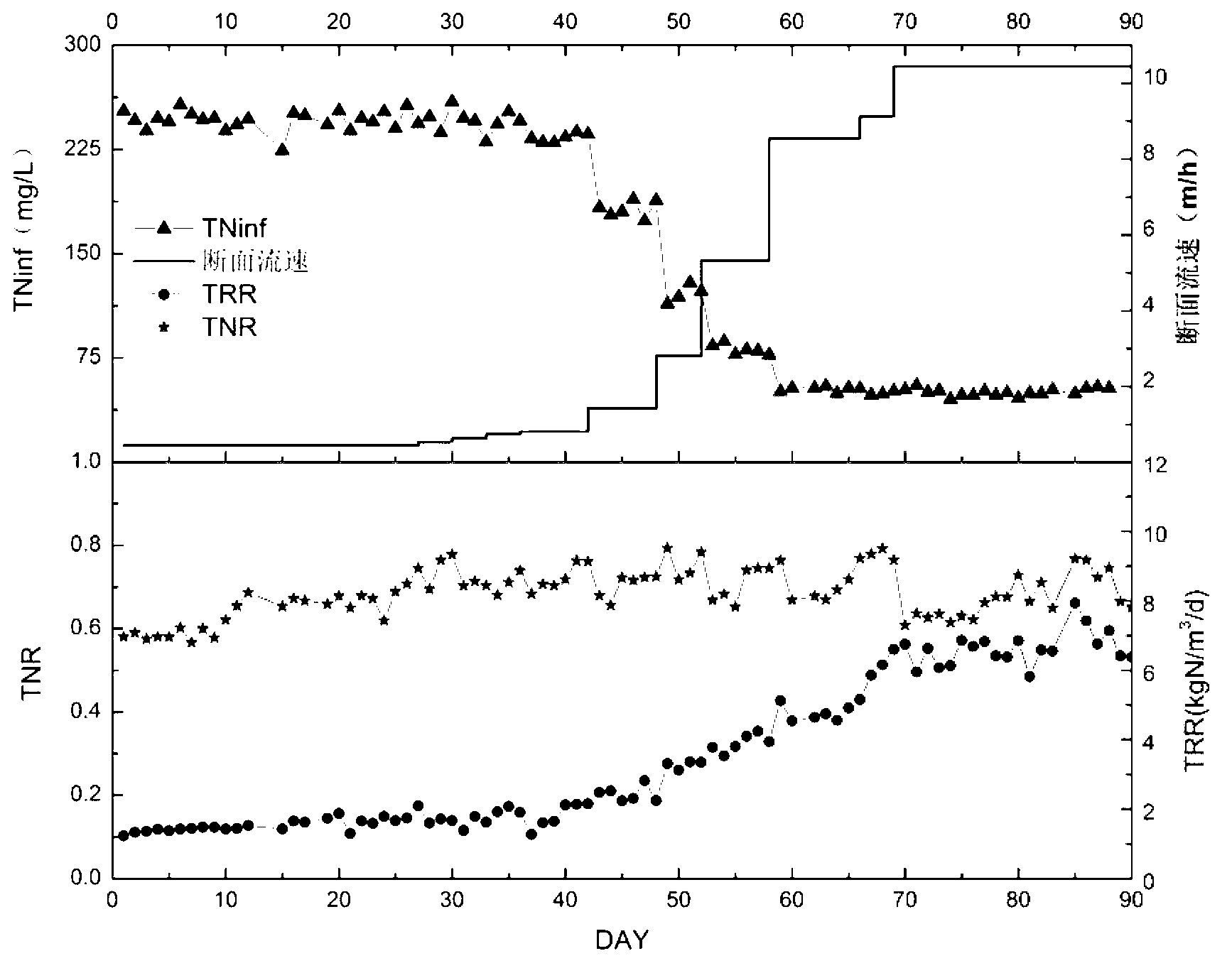

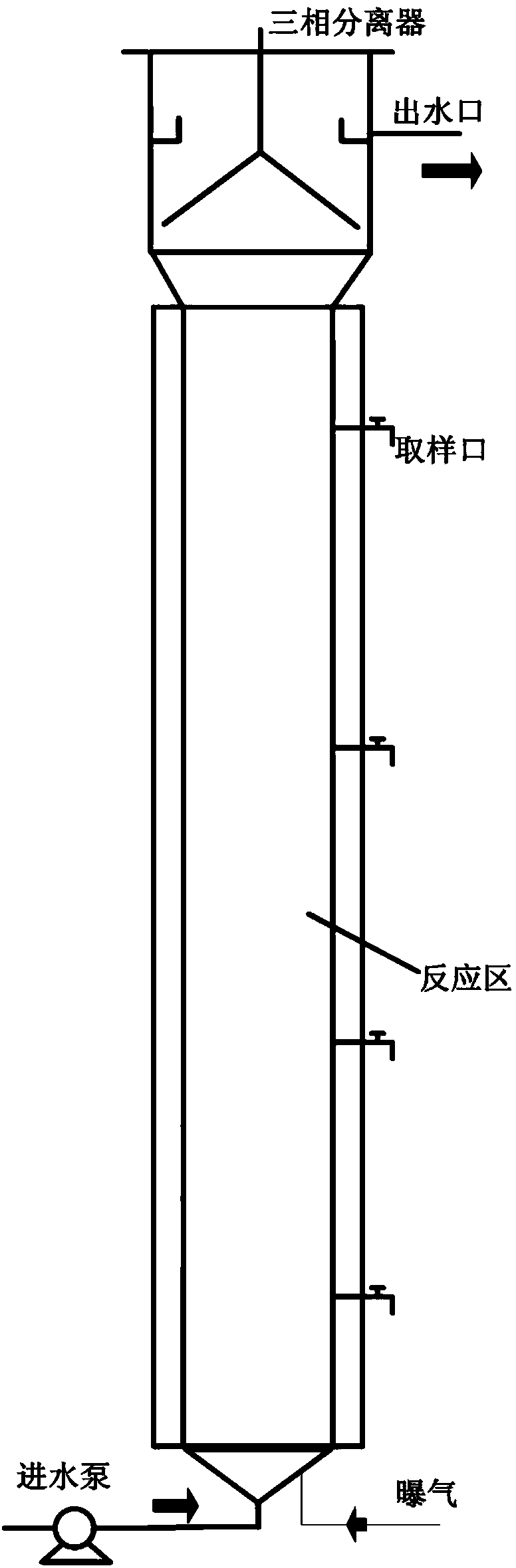

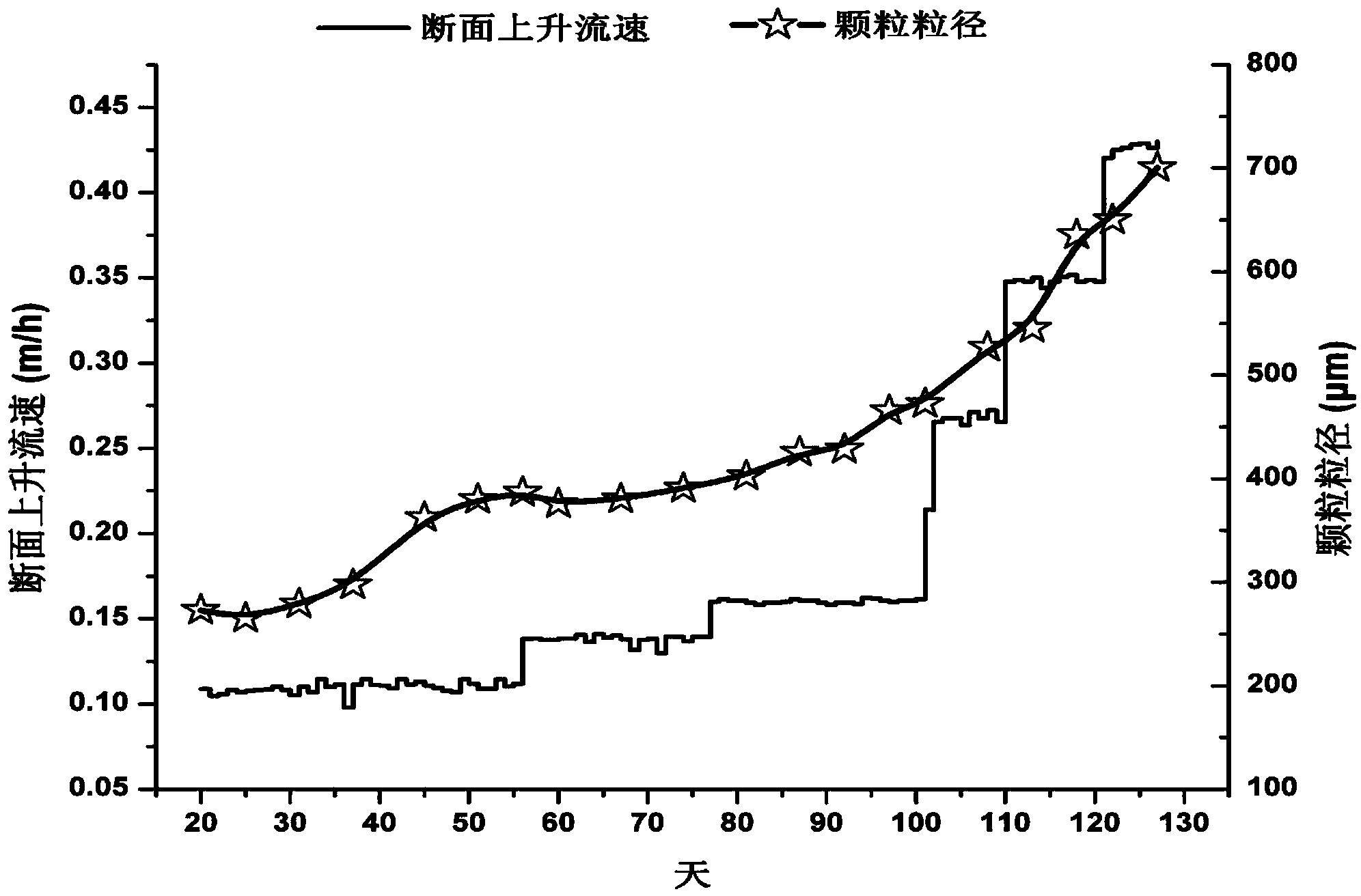

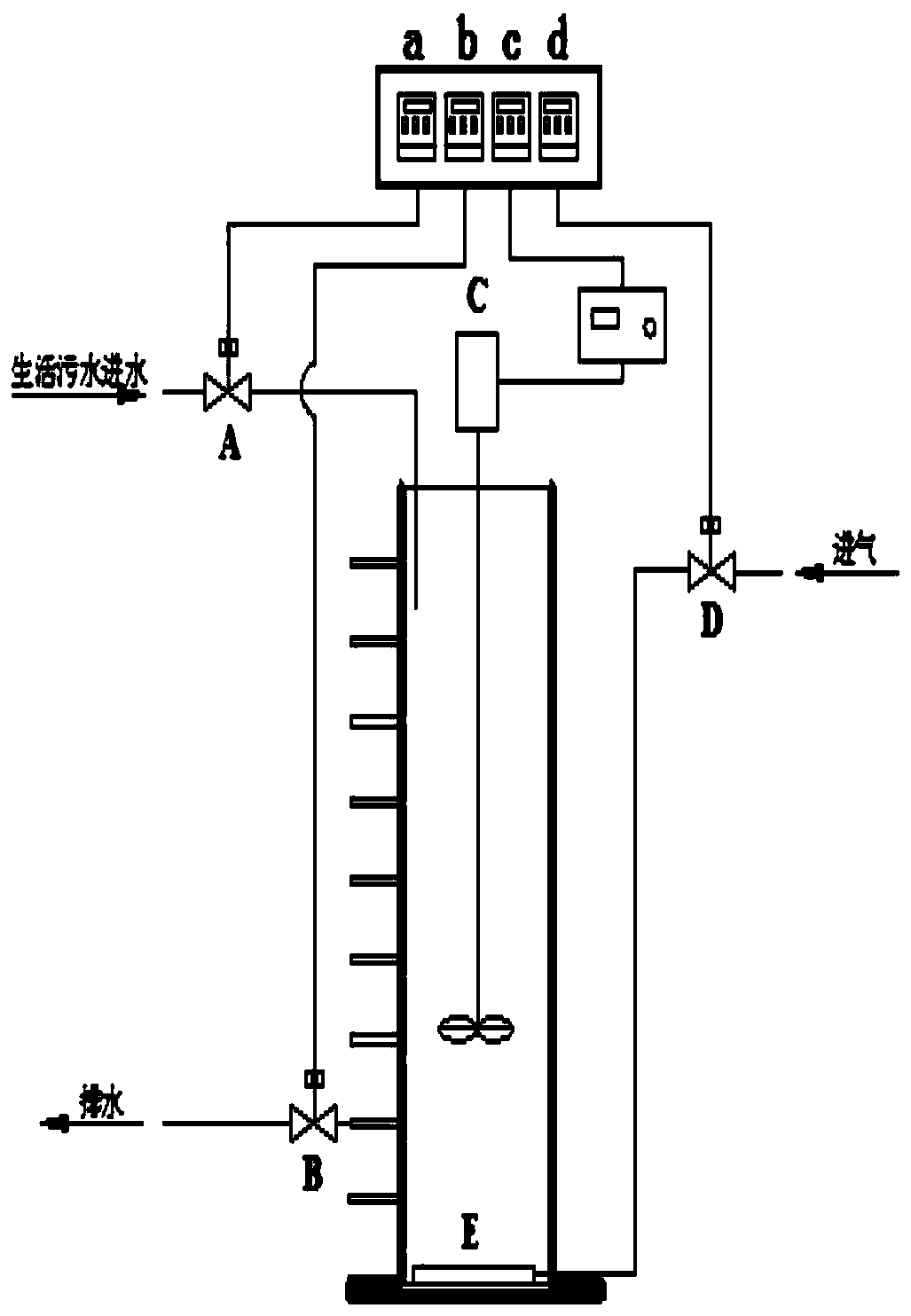

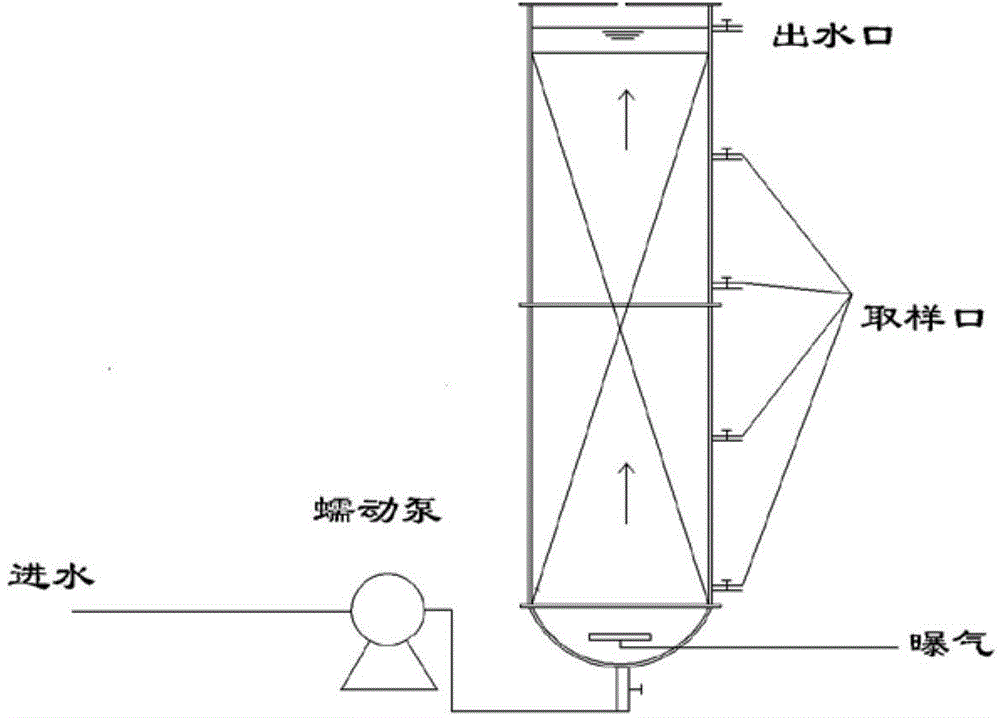

Anaerobic ammonia oxidization granule sludge starting method for treatment of urban sanitary sewage

ActiveCN103058365AThe scope of protection is not limitedTreatment with anaerobic digestion processesWater qualitySewage

The invention relates to an anaerobic ammonia oxidization granule sludge starting method for the treatment of urban sanitary sewage, and belongs to the field of water environment restoration and regeneration. According to the method, an upflow anaerobic sludge bed is adopted by a reactor; volcanic rock fillers with the particle diameter of 4 to 5mm are filled in one fourth to one third volume of the upper part of the reactor and are inoculated with the mature anaerobic ammonia oxidation and nitrosation mixing sludge, i.e. the granule sludge is cultured gradually at the low filtering rate; next, the granule sludge is cultured in a strengthening manner by continuously raising the section filtering speed; the treatment capacity of the granule sludge is strengthened by changing the water quality; and finally the granule sludge can be used for the treatment of the sanitary sewage. After 145 days, the average particle diameter of the granule sludge reaches 2.0mm, so that the granule sludge is capable of treating the sanitary sewage of 40 to 50mg / L, i.e. the water quality of effluent water reaches 1A standard, and the load reaches 3kg / m3 / d. Therefore, the method provided by the invention is suitable for the starting of an upflow anaerobic ammonia oxidization granule sludge reactor for the treatment of the urban sanitary sewage.

Owner:BEIJING UNIV OF TECH

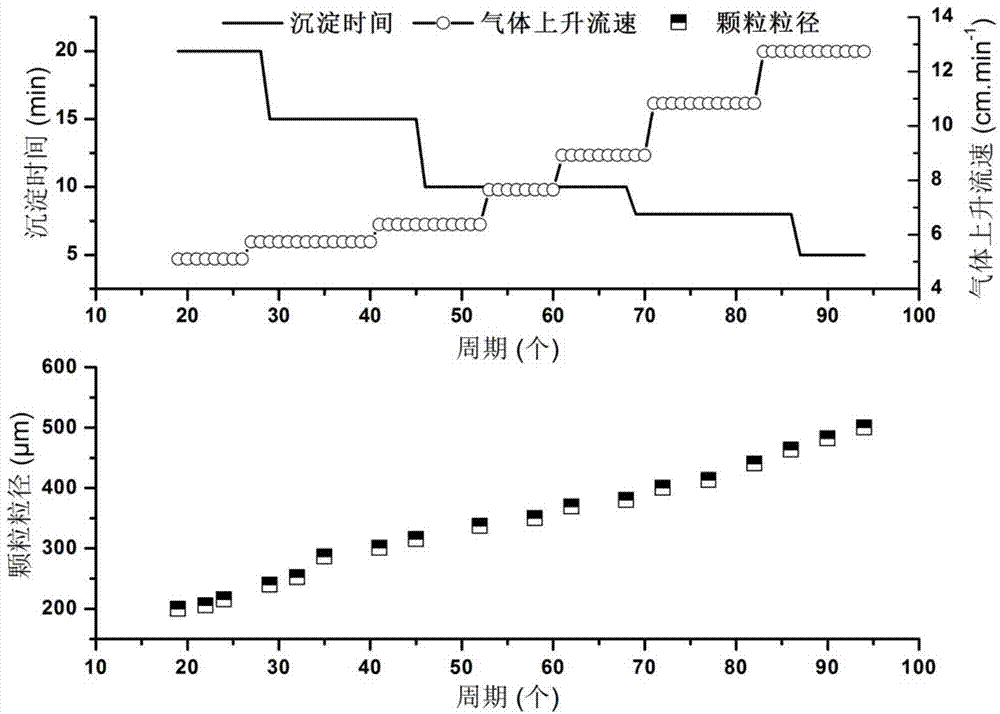

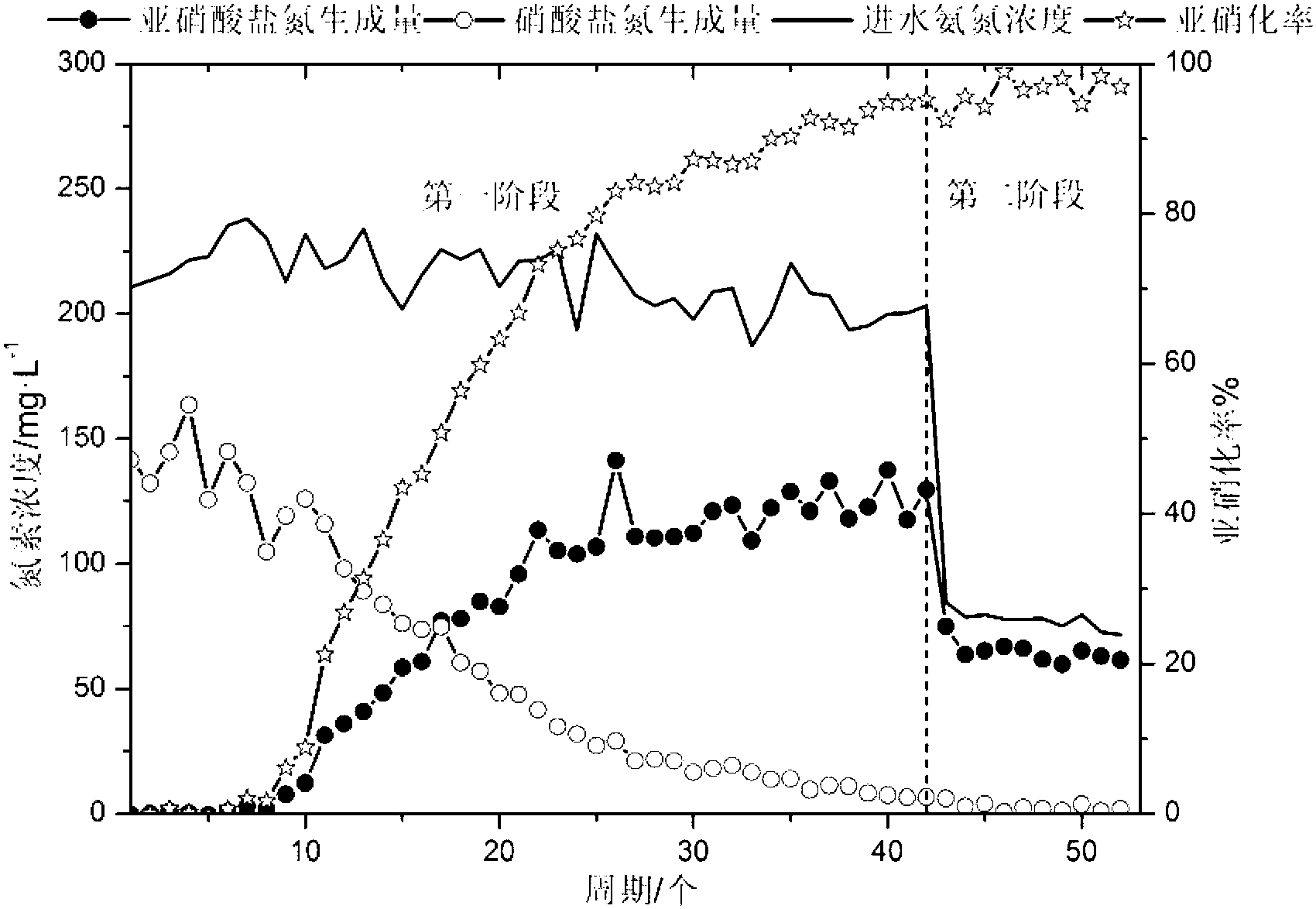

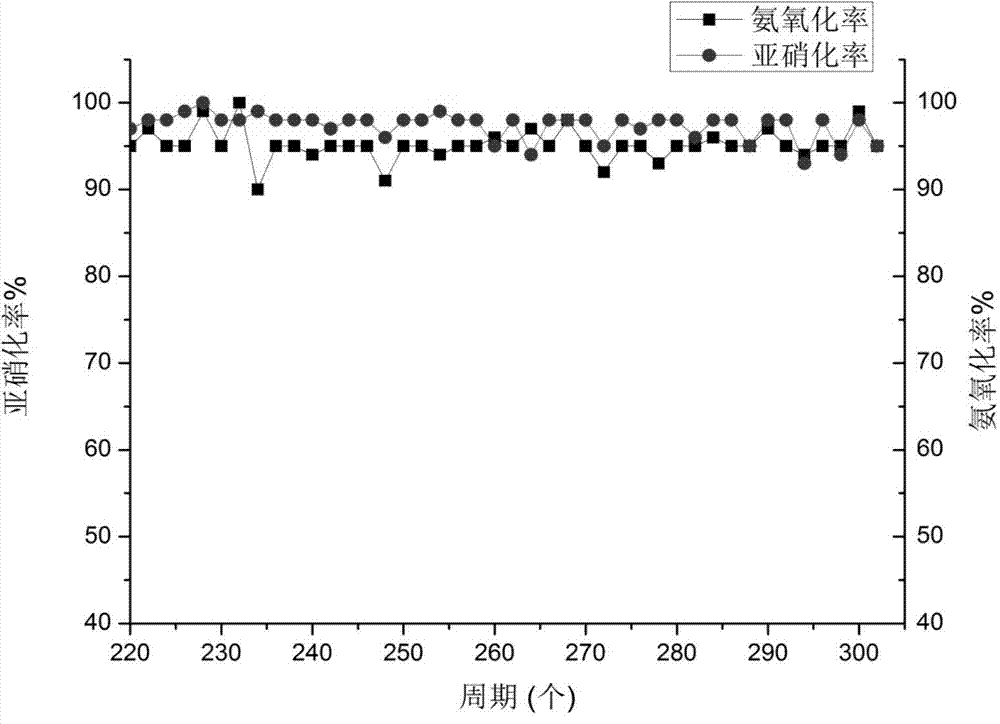

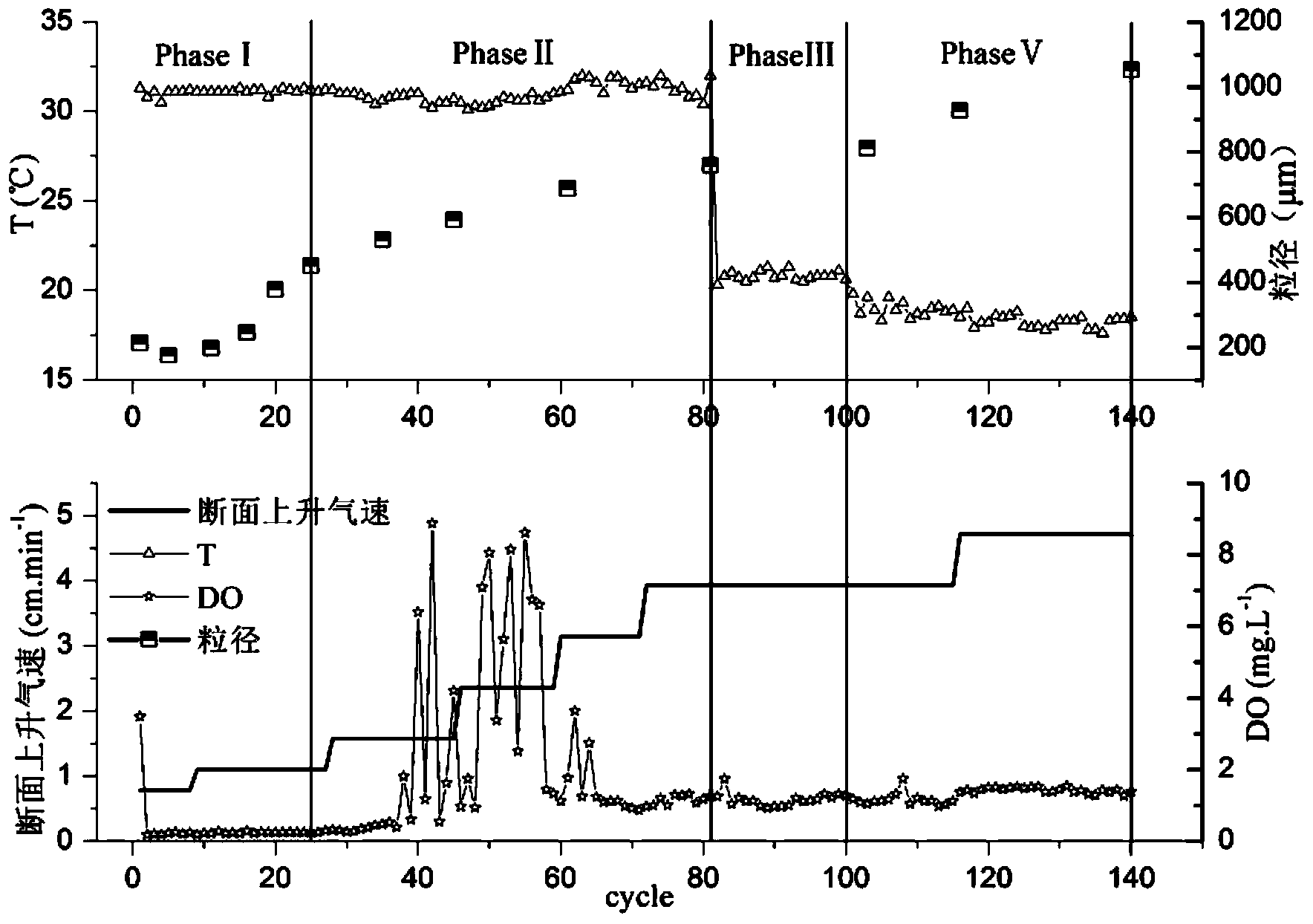

Culture method of granular nitrosation sludge for treating urban domestic sewage at normal temperature

ActiveCN103922466AStable nitrosation processHigh nitrosation rateSustainable biological treatmentBiological water/sewage treatmentAmmonia-oxidizing bacteriaSludge

The invention relates to a culture method of granular nitrosation sludge for treating urban domestic sewage at a normal temperature, and belongs to the field of water environment restoration and regeneration and the field of autotrophic nitrogen removal of sewage treatment plants. The method comprises the following steps: firstly, inoculating nitration sludge in a sewage plant and forming high free ammonia by utilizing the high ammonia nitrogen content and high pH (Potential Of Hydrogen) of the digested sludge so as to eliminate NOB (Nitrite Oxidizing Bacteria) and purify AOB (Ammonia Oxidizing Bacteria), thereby realizing the stable running of a nitrosation process; then, replacing the feeding water with the urban domestic sewage and manually adding ammoniacal nitrogen so as to continuously accelerate the gas ascending velocity and increase the gas shearing force to gradually shorten the precipitation time, regulating the aeration quantity to guarantee the certain total nitrogen loss, the certain ammonia oxidation rate and the certain nitrosation rate so as to realize flocculent sludge granulation; finally, replacing the feeding water with the urban domestic sewage and enhancing the treatment performance of the sludge. Thus, the granular nitrosation sludge for treating the urban domestic sewage at the normal temperature is successfully cultured.

Owner:BEIJING UNIV OF TECH

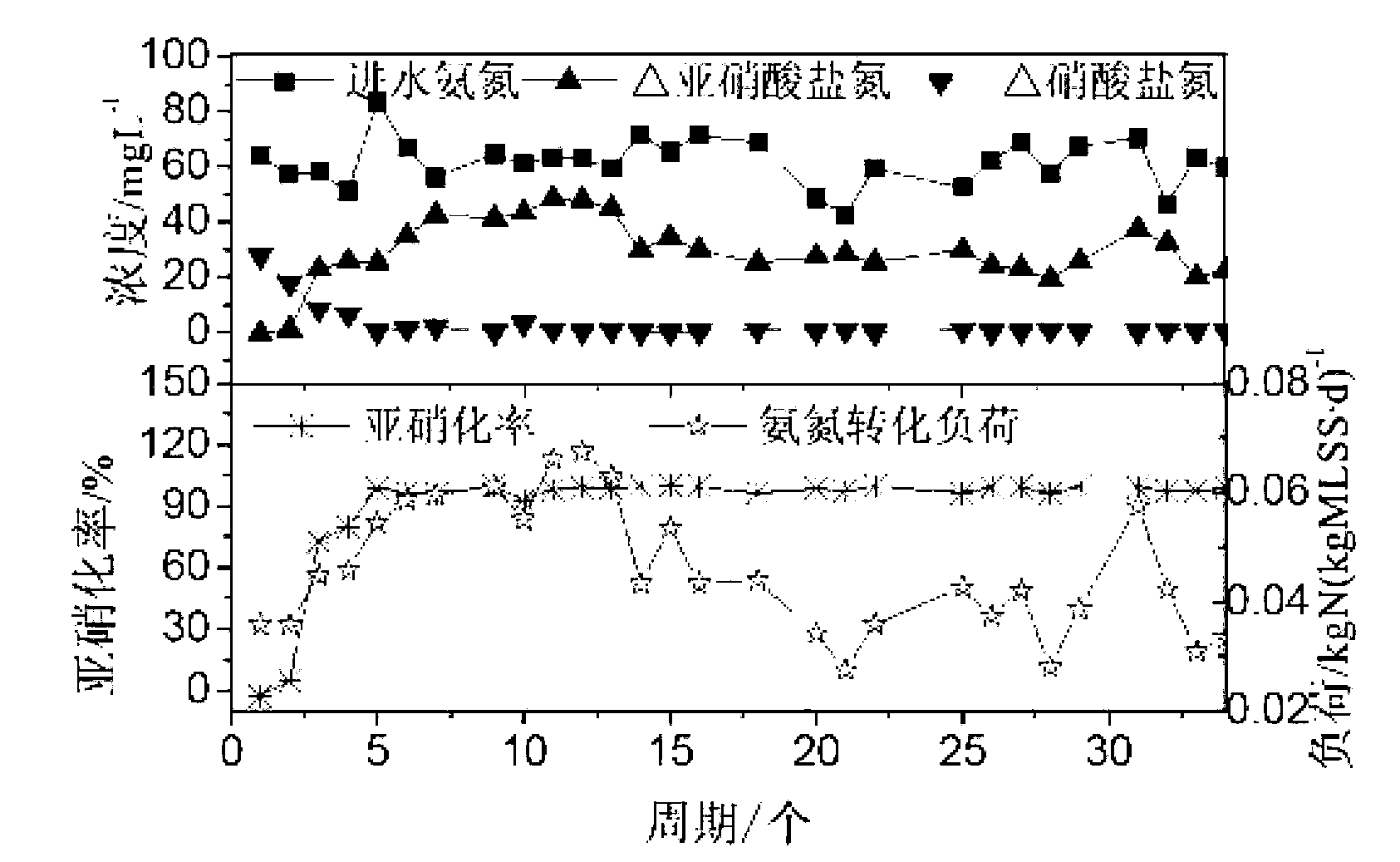

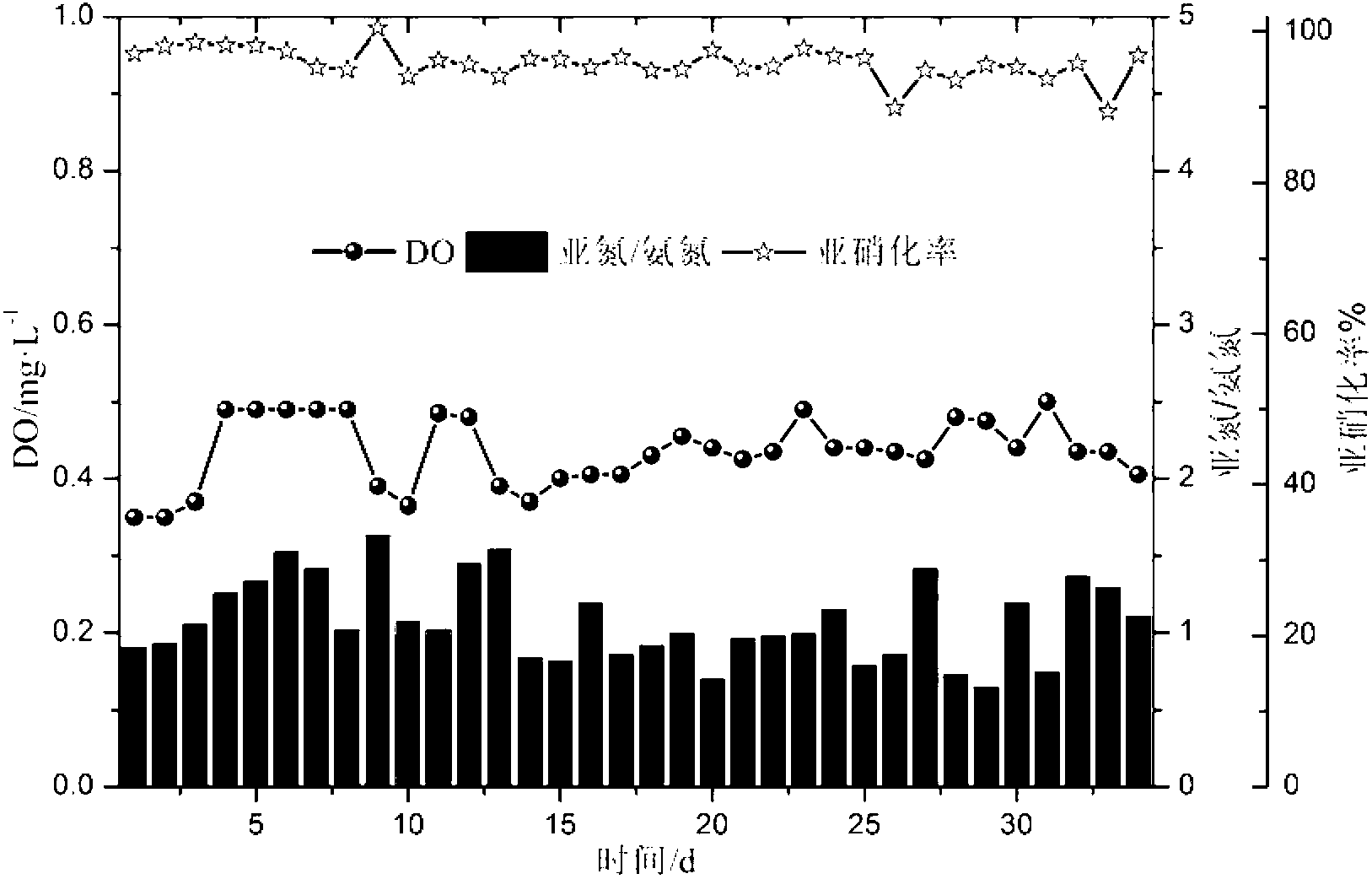

Normal temperature low-ammonia-nitrogen nitrosation starting method

InactiveCN102701438AStart fastHigh speedSustainable biological treatmentBiological water/sewage treatmentNitriteResearch Object

A normal temperature low-ammonia-nitrogen nitrosation starting method belongs to the field of urban sewage treatment and reclamation. Researches show that nitrosation starting can be achieved in short time by controlling condition of low dissolved oxygen (DO=0.30mg / L) and inoculating sludge with certain nitrosation effect. If whole course nitration sludge is inoculated, no accumulation of nitrite occurs within 30 days in a water distribution test, no accumulation of nitrite occurs in 30 days in a reactor which utilizes the A / O dephosphorization process processing water as a research object, and the nitrosation starting fails accordingly. Nitrite accumulation can occur by adopting the mode of high-low gradient oxygen limit culture, domesticating the sludge for 10 days under the condition that DO=0.70-0.80mg / L, then controlling condition of low dissolved oxygen (0.30-0.40mg / L) to enable the reactor to discharge water if the whole course nitration sludge is inoculated. Over 90% of nitrosation rate can be achieved within 38 days by continuously domesticating the sludge under the condition of the dissolved oxygen, so that nitrosation can be successfully started.

Owner:BEIJING UNIV OF TECH

Method for treating arsenic in non-ferrous smelting waste acid by using iron-rich copper slag

InactiveCN109621276AIncrease management costsSusceptible to toxic leachingChemical protectionSludgeBall mill

The invention discloses a method for treating arsenic in non-ferrous smelting waste acid by using iron-rich copper slag, and belongs to the field of heavy metal pollution control and metallurgical solid waste utilization. The method comprises: carrying out oxidizing pretreatment on non-ferrous smelting waste acid, and carrying out drying grinding on iron-rich copper slag; adding the iron-rich copper slag to the pretreated non-ferrous smelting waste acid, carrying out an arsenic removal reaction by stirring under a normal pressure, and carrying out solid-liquid separation to obtain arsenic-containing copper slag; and carrying out ball milling magnetic separation on the arsenic-containing copper slag to separate copper slag and arsenic-rich solid waste, wherein the separated copper slag is recycled, and the arsenic-rich solid waste is subjected to safe disposal or secondary utilization. Compared with the traditional arsenic removal process, the method of the present invention can reducethe sludge storage amount during the waste acid treatment so as to treat the waste with the waste, and further has advantages of simple process operation, low production cost and broad market prospects.

Owner:KUNMING UNIV OF SCI & TECH

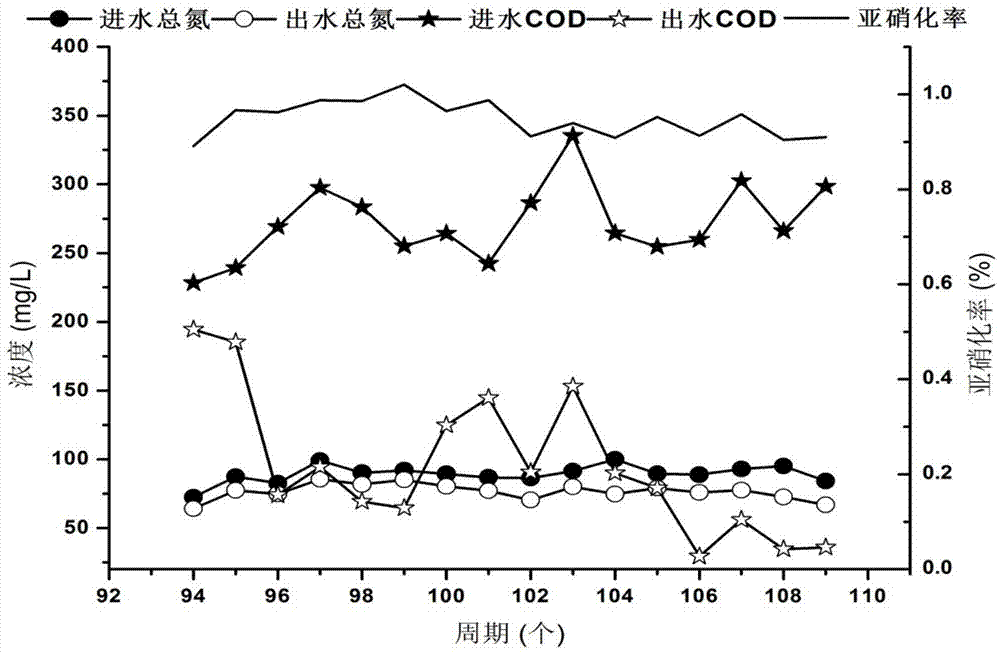

Method for regulating and controlling nitrogen proportion of partial nitrosation effluent of low-ammonia-nitrogen continuous stirred-tank reactor (CSTR) at normal temperature

ActiveCN102701441ALow costReduce volumeWater contaminantsTreatment with anaerobic digestion processesActivated sludgeSequencing batch reactor

The invention provides a method for regulating and controlling nitrogen proportion of partial nitrosation effluent of low-ammonia-nitrogen continuous stirred-tank reactor (CSTR) at normal temperature and belongs to the field of municipal wastewater treatment and recycling. The starting is performed in a four-stage mode, and 80%-100% of ammoxidation load in the low-ammonia-nitrogen operation period of sequencing batch reactor activated sludge process (SBR) serves as initial ammoxidation load of the CSTR to confirm hydraulic retention time (HRT) of the CSTR. DO / ALR serves as an iconic parameter for maintaining a nitrosation system, and a value of the iconic parameter is recommended to be not greater than 1.0 mgO2 / gNd and is regarded as the regulating and controlling standard of the DO and the HRT. First, the HRT is constant, the DO is controlled singly, if the proportion is not reached or the ammoxidation load is not enough, the DO and the HRT can be regulated and controlled synchronously. The NO2--N / NH4+-N and ammonia-nitrogen oxidation rate (a) / nitrite nitrogen generating rate (b) and nitrite nitrogen generating rate (b) / nitrate nitrogen generating rate (c) of the effluent are compared. If an average value of the proportions of the effluent under the different working conditions is in a range of 1-1.32:1, when b / a is greater than 0.9 and more approximates to 1.0, b / c is greater, and the working condition is more suitable for long-term operation of the system. The NO2--N / NH4+-N of the effluent of the CSTR is guaranteed to be in a range of 1-1.32:1 so as to meet the water feeding requirement of an anaerobic oxidation technology.

Owner:BEIJING UNIV OF TECH

High-efficiency low-consumption biological denitrification method for urban sewage

InactiveCN101343117AAchieving autotrophic denitrificationBiological denitrification is simple and efficientTreatment with aerobic and anaerobic processesHigh energyResource utilization

Disclosed is a high-efficiency and low-consumption biological denitrogenation method of urban sewage, which belongs to the fields of urban sewage disposal and resource utilization. The method aims to solve the problem of high energy and material consumption of the current urban sewage biological denitrogenation method. The method comprises: adopting a biomembrane filter chamber system under normal temperature, making the same biomembrane filter chamber system adapt to the respective growth metabolism condition of nitrite bacteria and anaerobic ammonium oxidation bacteria through adjusting the equipment operation parameters of a reactor, rapidly realizing the successful startup of the urban sewage anaerobic ammonium oxidation biological autotrophic denitrogenation reactor, and enabling the biomembrane filter chamber system to achieve the purpose of stabilizing the denitrogenation with high efficiency and low consumption through controlling the operational parameters of the reactor and relying on the synergic denitrogenation function of nitrite bacteria and anaerobic ammonium oxidation bacteria. The method applies a new discovery in science of a simple process of anaerobic ammonium oxidation biological autotrophic denitrogenation to the high-efficiency and low-consumption denitrogenation treatment of urban domestic sewage for the first time, and has the advantages of short startup period of the system, stable running, excellent effects of sewage disposal and low cost.

Owner:BEIJING UNIV OF TECH

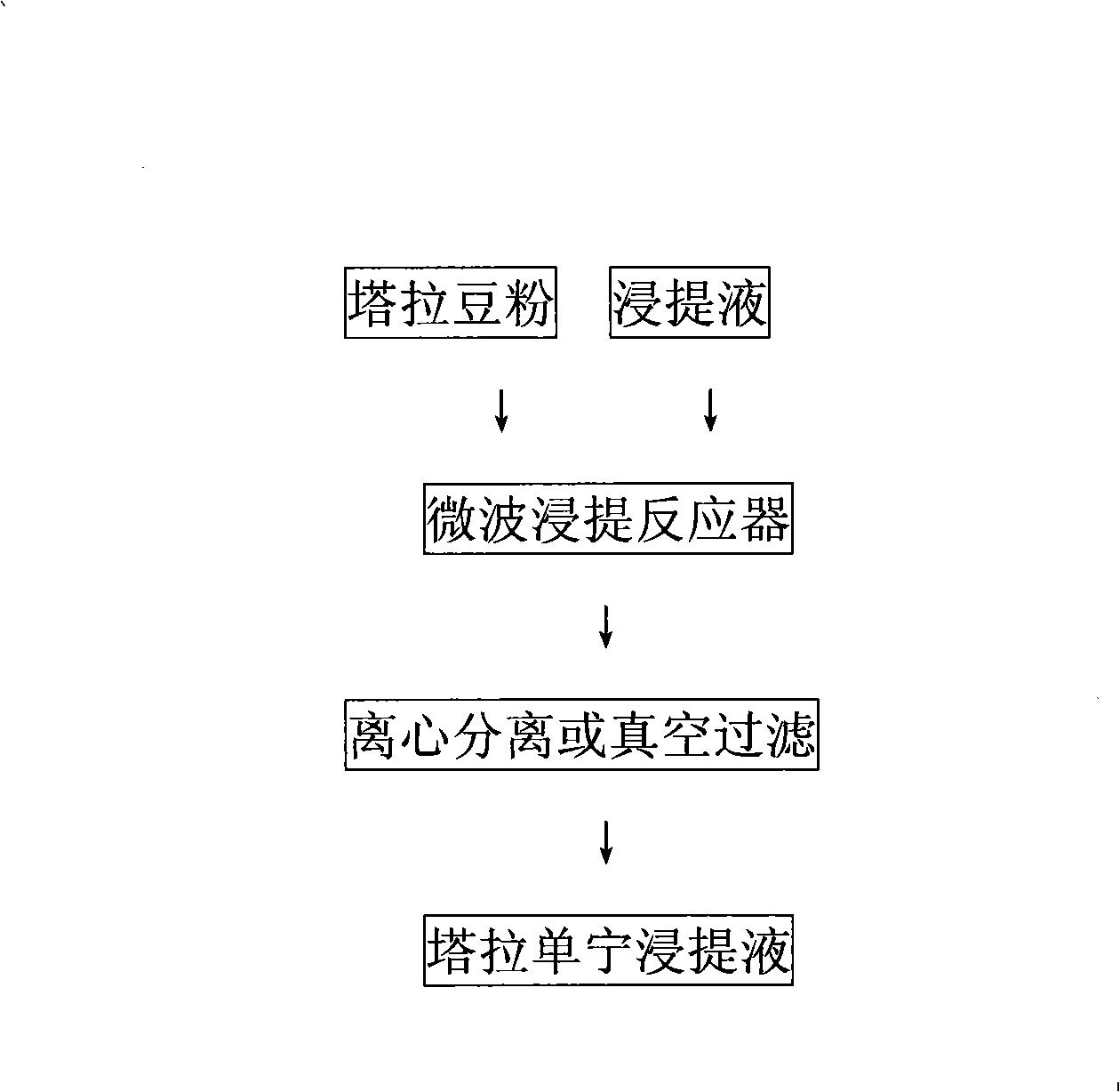

Method for extracting tannin from tarra bean-pod by micro-wave method

The invention relates to a method for extracting tannin from tara legume in water or ethanol through microwave radiation with a certain strength. The method includes radiating tara bean flour and water or ethanol at solid to liquid ratio of 1:4-10 with a microwave strength of 15-45 W / L for 30-120 min. for extracting at 40-80 DEG C at a stirring rate of 40-80 rpm, centrifugally separating or vacuum filtering, and collecting the filtrate, i.e., tara tannin solution. The tara bean flour is radiated with microwave to allow tannin polar molecule in the tara bean flour to rapidly enter into the leaching solution. The extraction rate of the tara tannin is greater than 70%. Compared with the conventional cooking method, the microwave extraction method of the tara tannin has the advantages of simple process, high extraction efficiency, energy saving effect, advanced process, high efficiency, short period, good economic and operability.

Owner:云天化集团有限责任公司 +1

Compound microorganism bacterium agent and application thereof in eutrophic water body treatment

InactiveCN104045166AAdaptableReduce pollutant indexBiological water/sewage treatmentAlcaligenes faecalisEutrophic water

The invention relates to a compound microorganism bacterium agent which consists of Rhodopseudomonas palustris bacteria liquid, Alcaligenes faecalis bacteria liquid, Acinetobacter calcoaceticus bacteria liquid and bacillus megatherium bacteria liquid according to a volume ratio of 1:(2-3):4:2, wherein the amount of viable organisms in the four kinds of bacteria liquid is 2*10<8>cfu / ml. The invention also provides application of the compound bacterium agent in eutrophic water body treatment. The water body is subjected to pollution treatment through the four composite microbes, so that polluted substances in the water body are decomposed and metabolized, pollutants in the water body are degraded by stimulating growth of indigenous microorganisms in the environment, the index of each pollutant in the treated water body is obviously reduced, the dirt removal effect is good, and the removal rate is high.

Owner:HENAN UNIVERSITY

Starting method of CANON granule sludge of regeneration urban sewage

ActiveCN103896394AAmmonia oxidation rate is highGood removal effectSustainable biological treatmentBiological water/sewage treatmentNitrogen removalSludge

The invention relates to a starting method of CANON granule sludge of regeneration urban sewage and belongs to the field of water environmental return and regeneration and the field of sewage treatment plant autotrophic nitrogen removal. The starting method comprises the following steps: firstly inoculating CANON biological filter column to back wash the sludge, diluting the urban sewage by running water, and ensuring stable operation of CANON process under high ammonia nitrogen conditions; then reducing substrate concentration and continuously improving section rising gas velocity, and adjusting the reaction time to ensure a certain ammonia oxygenation rate and total nitrogen removal rate to realize flocculent sludge granulation; finally changing inlet water to the urban sewage to enhance the processing performance. By utilizing the starting method, starting of the CANON granule sludge of the regeneration urban sewage is successfully realized in an intermittent flow manner.

Owner:BEIJING UNIV OF TECH

Thymus plant extract and application thereof

ActiveCN106344648ASmall side effectsSignificant effectNervous disorderMetabolism disorderDiseaseSide effect

The invention relates to a thymus plant extract or composition and application thereof. The preparation method comprises the following steps: firstly quenching active pharmaceutical ingredients with acetone; performing acidification by use of H2SO4 with certain concentration; extracting the extracting solution with ethyl acetate for 2-3 times, thereby obtaining a thymus plant extract containing carvacrol, tanshinol, scutellarein, scutellarin, 5,4'-dyhydroxyl-6,7,8-trimethoxy flavone, oleanolic acid and rosmarinic acid. The thymus plant also provides a traditional Chinese medicine composition for treating cardiovascular and cerebrovascular disease. The traditional Chinese medicine composition is prepared from the following active pharmaceutical ingredients in parts by weight: 200-500 parts of thymus plant, 100-300 parts of curcuma roots, 100-300 parts of rhizoma sparganii, 200-400 parts of radix angelica sinensis, 100-200 parts of ginkgo leaves, 100-200 parts of licorice root, 200-400 parts of radix codonopsis pilosulae and 200-500 parts of rhizoma ligustici wallichii. The traditional Chinese medicine composition is rapid in medical effect taking and less in toxic and side effects, thereby being a favorable medicament for treating cardiovascular and cerebrovascular diseases.

Owner:折改梅

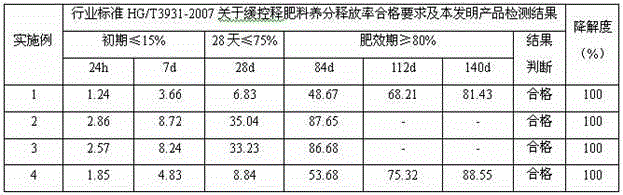

Slow controlled release fertilizer coating agent

InactiveCN104130067ASynchronization of requirementsAchieve dynamic balanceFertilizer mixturesEnvironmental engineeringRaw material

The invention discloses a slow controlled release fertilizer coating agent which is scientifically prepared from lignite wax resin, humate, a resin solvent and lignite essence. The coating materials with different controlled release rates are prepared by regulating the ratio of the lignite wax resin to the humate via utilization of the hydrophily of the humate and the hydrophobicity of the lignite wax resin and the different biological functions of the humate and the lignite wax resin, so that the purpose of mutual long-acting and quick-acting coordination is realized. The coating agent disclosed by the invention conforms to the concepts of 'fertilizer coated by fertilizer' and 'soil nourished by soil'. The selected materials for preparing the coating agent can be completely and naturally degraded, and degradation products can be used for improving soil environment and stress resistance of crops. In addition, the coating agent is simple in preparation process, easily available in raw materials, low in production cost and easy to popularize.

Owner:KUNMING UNIV OF SCI & TECH

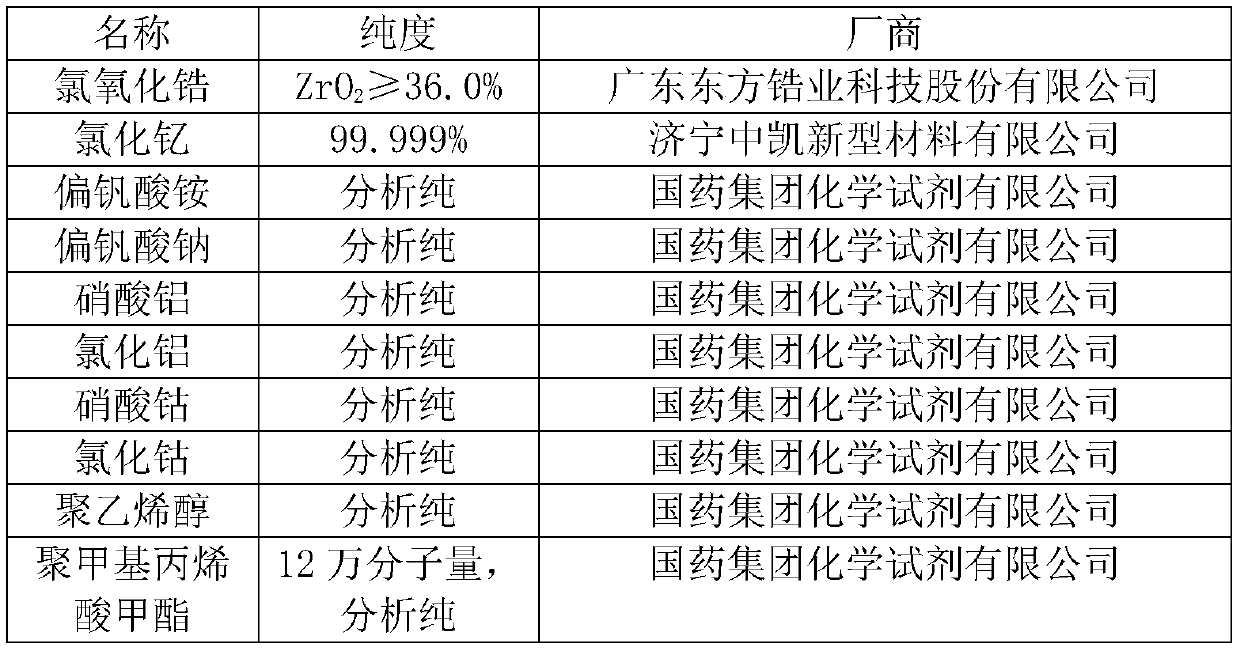

Green zirconia ceramics and preparation method thereof

PendingCN110002867ASmall mechanical propertiesSolve the problem that cannot be completely precipitatedCoprecipitationCobalt aluminate

The invention discloses green zirconia ceramics and a preparation method thereof, and belongs to the field of ceramic materials. The preparation method comprises the following steps: firstly preparinga zirconium hydroxide precursor by a coprecipitation technology, then adding metal salts of vanadium, cobalt and aluminum into the precursor, drying and sintering to prepare zirconia granulated powder containing vanadium pentoxide and cobalt aluminate, and molding and sintering the powder to prepare the green zirconia ceramics. By adjusting content and proportion of a colouring agent (vanadium pentoxide and cobalt aluminate) in the zirconia powder, the green chroma of the zirconia ceramics can be adjusted. According to the invention, the problem that a pigment cannot reach the uniform dispersion state of grain size due to existing physical pigment mixing methods and the problem that the coprecipitation addition mode of a colouring agent easily leads to incomplete precipitation of metal salts are solved.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

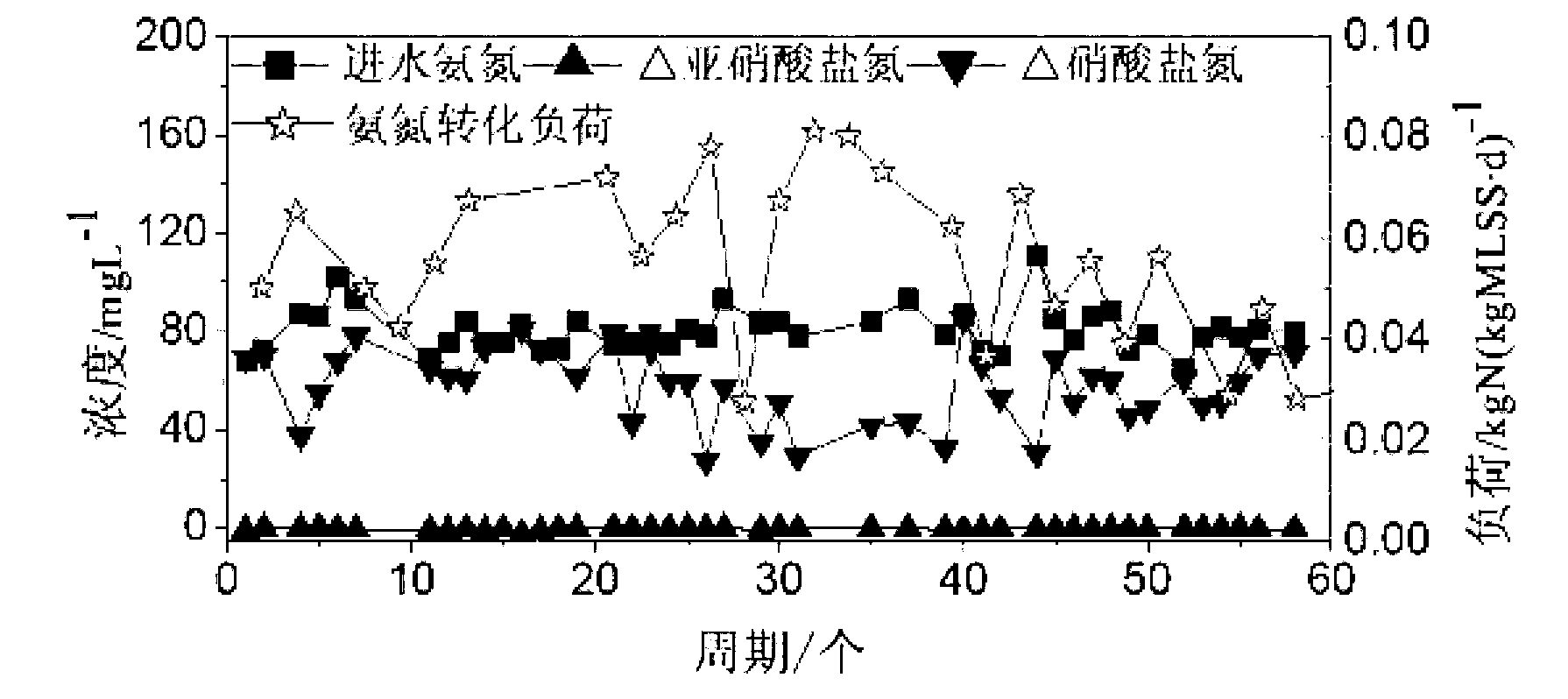

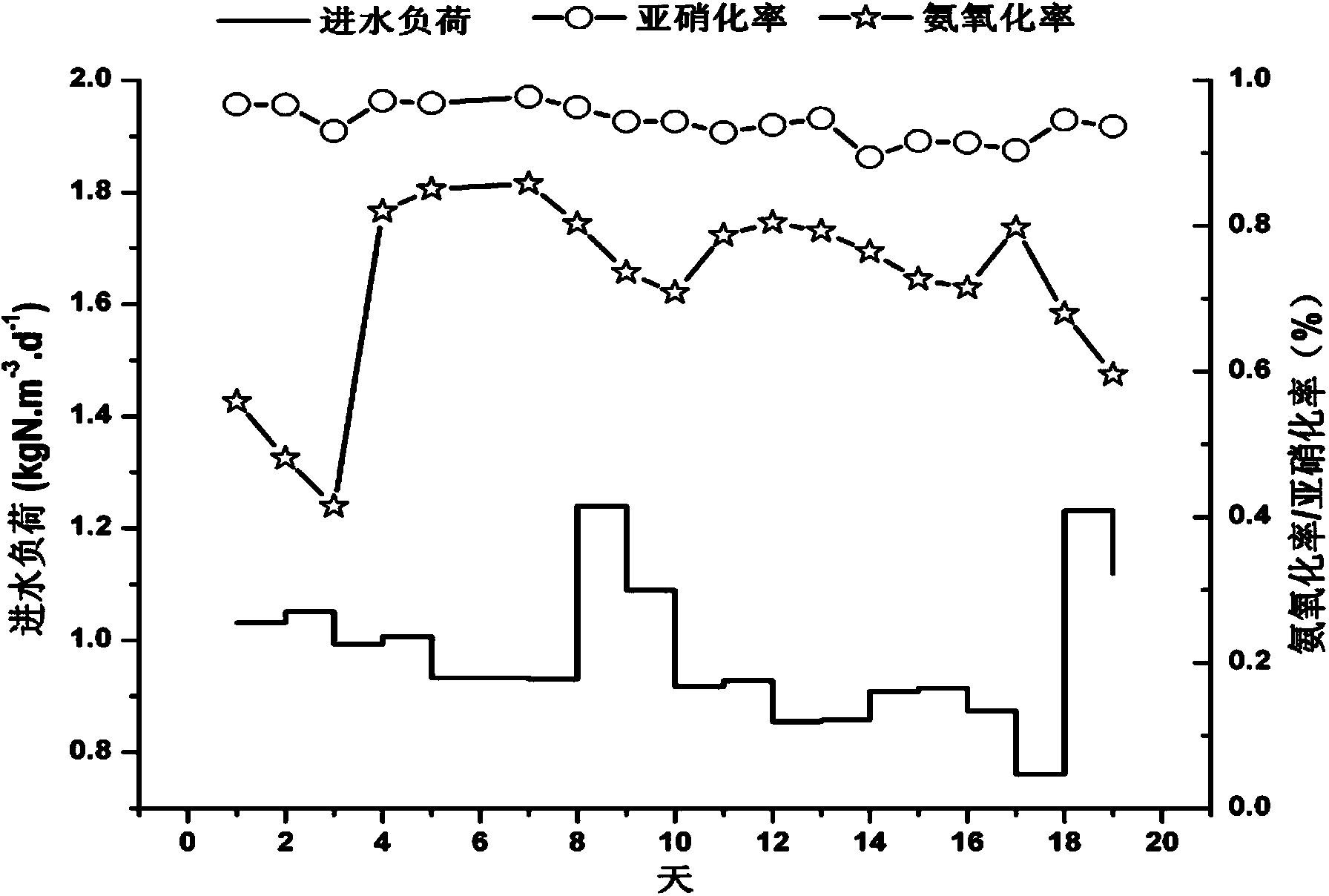

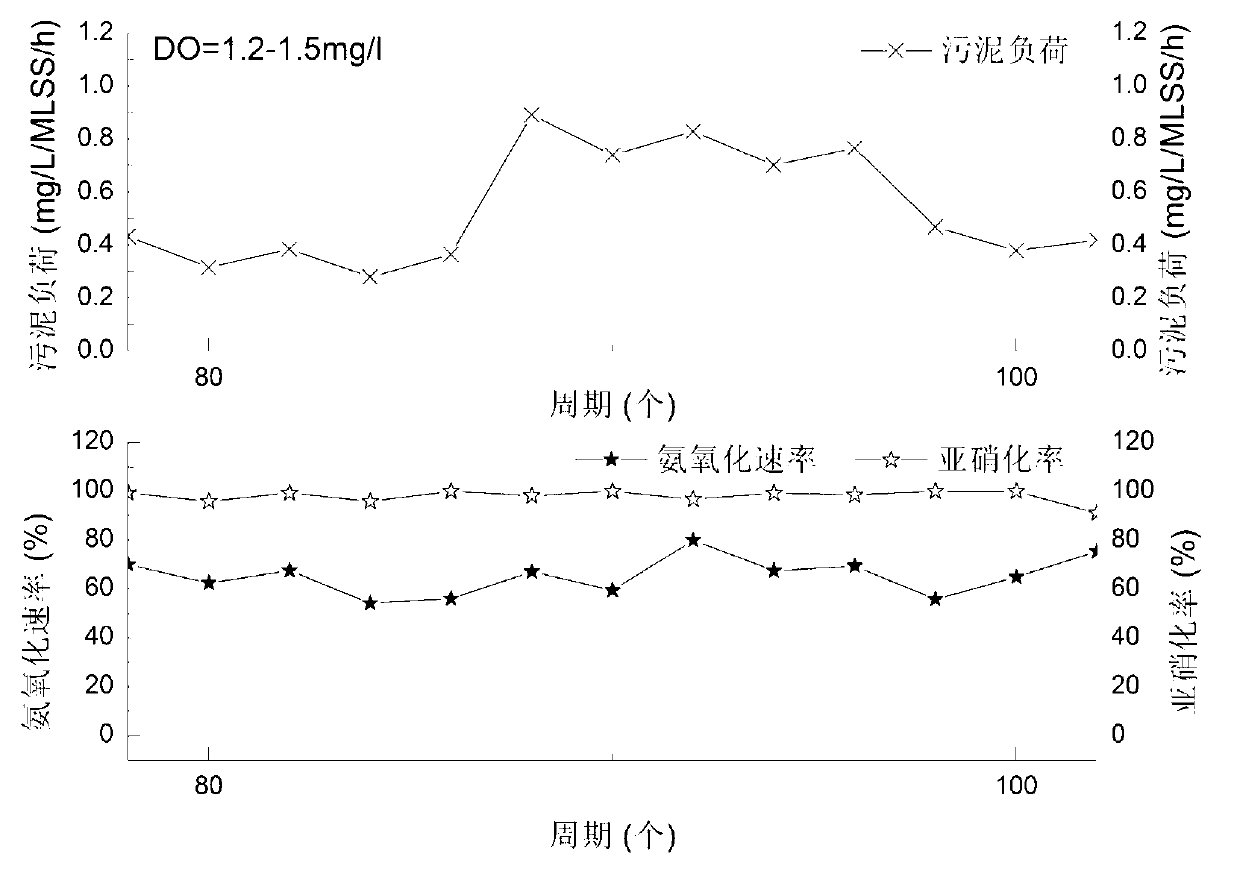

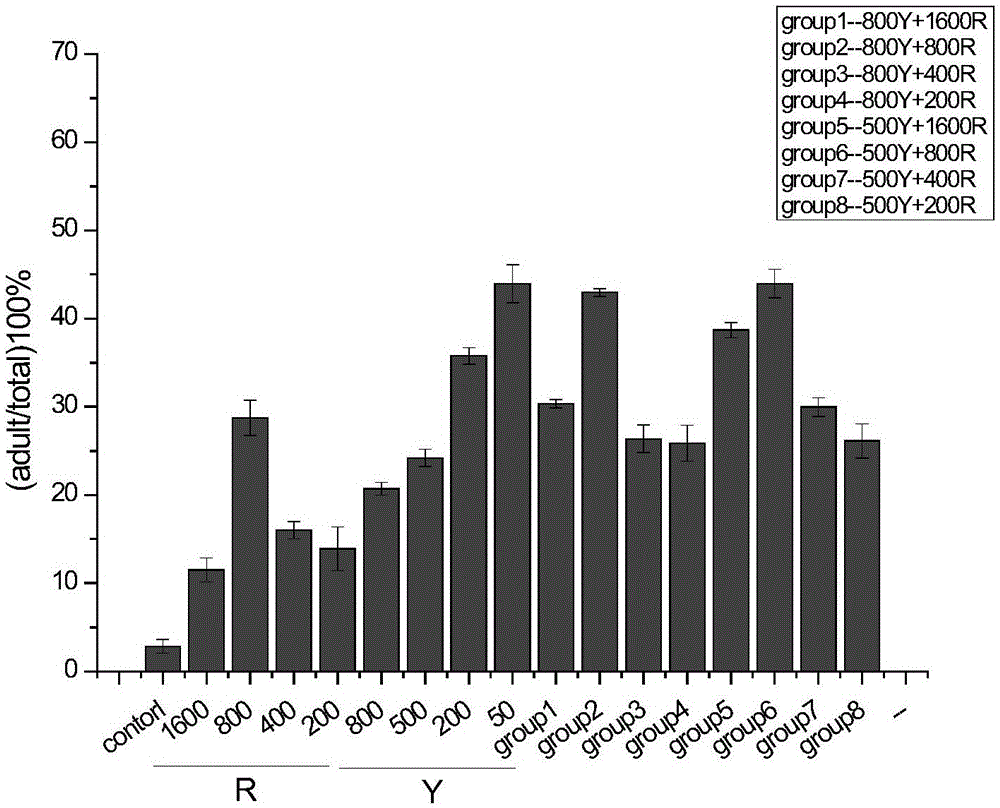

Method for cultivating aerobic half-nitrosation granular sludge in continuous flow manner

ActiveCN103663680AEasy to trainStable semi-nitrosation processSustainable biological treatmentBiological water/sewage treatmentRetention timeAmmonia-oxidizing bacteria

A method for cultivating aerobic half-nitrosation granular sludge in a continuous flow manner comprises the following steps: firstly, inoculating floccular nitrosation sludge to ensure that the flocculent nitrosation sludge can adapt to a continuous flow reactor, and building a microbial system taking aerobic ammonia-oxidizing bacteria as a main material; then adjusting the ascending velocity and aeration quantity on a certain section, so as to realize floccular sludge granulation on the basis that the ammoxidation rate and the nitrosation rate are certain; finally, unceasingly accelerating the ascending velocity and aeration quantity the section to improve the water flow shearing force and ensure that particle size grows fast. The aeration time and hydraulic power retention time are adjusted to ensure that the ammoxidation rate and the nitrosation rate are higher than 60 percent and 80 percent respectively, and the particle size grows in an enhanced manner. Therefore, the cultivation of aerobic half-nitrosation granules in the continuous flow manner is realized successfully.

Owner:BEIJING UNIV OF TECH

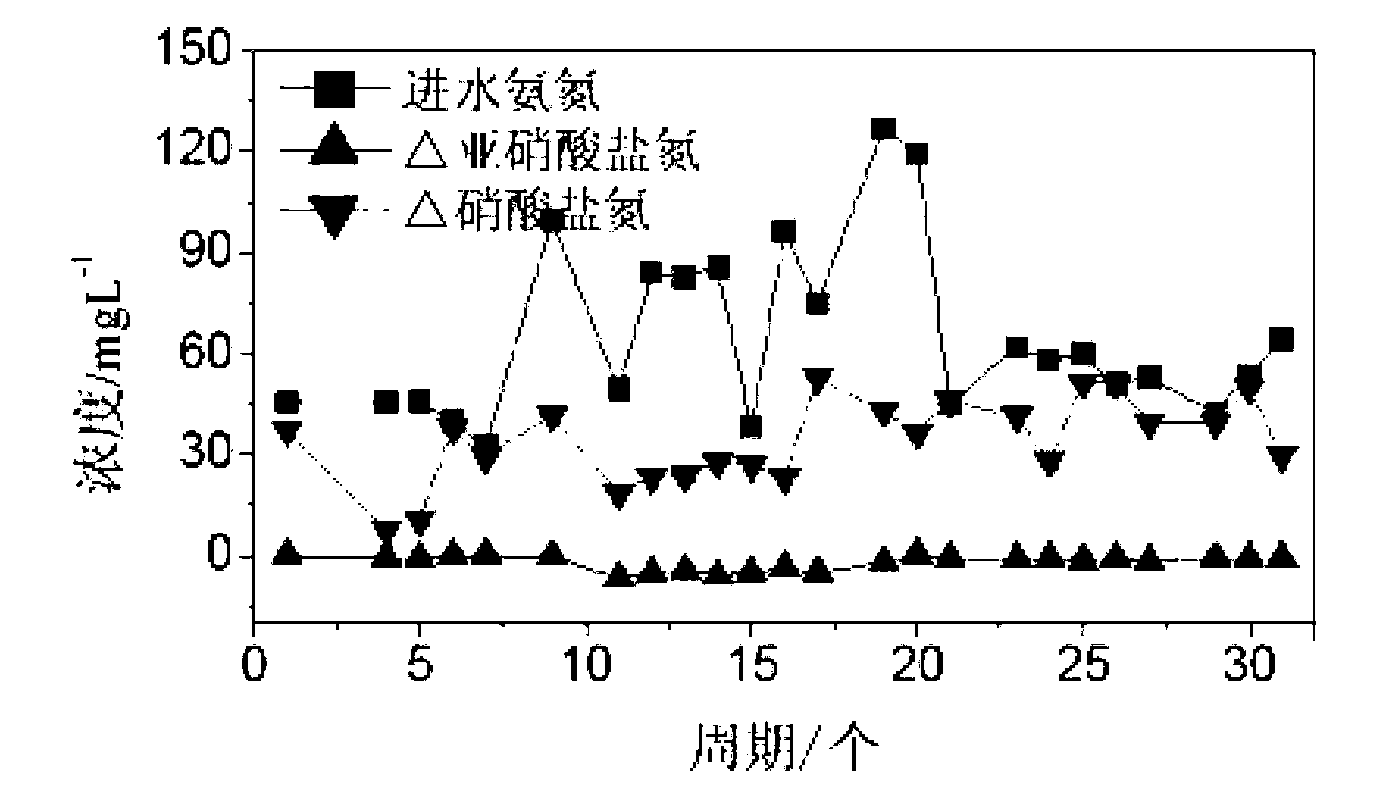

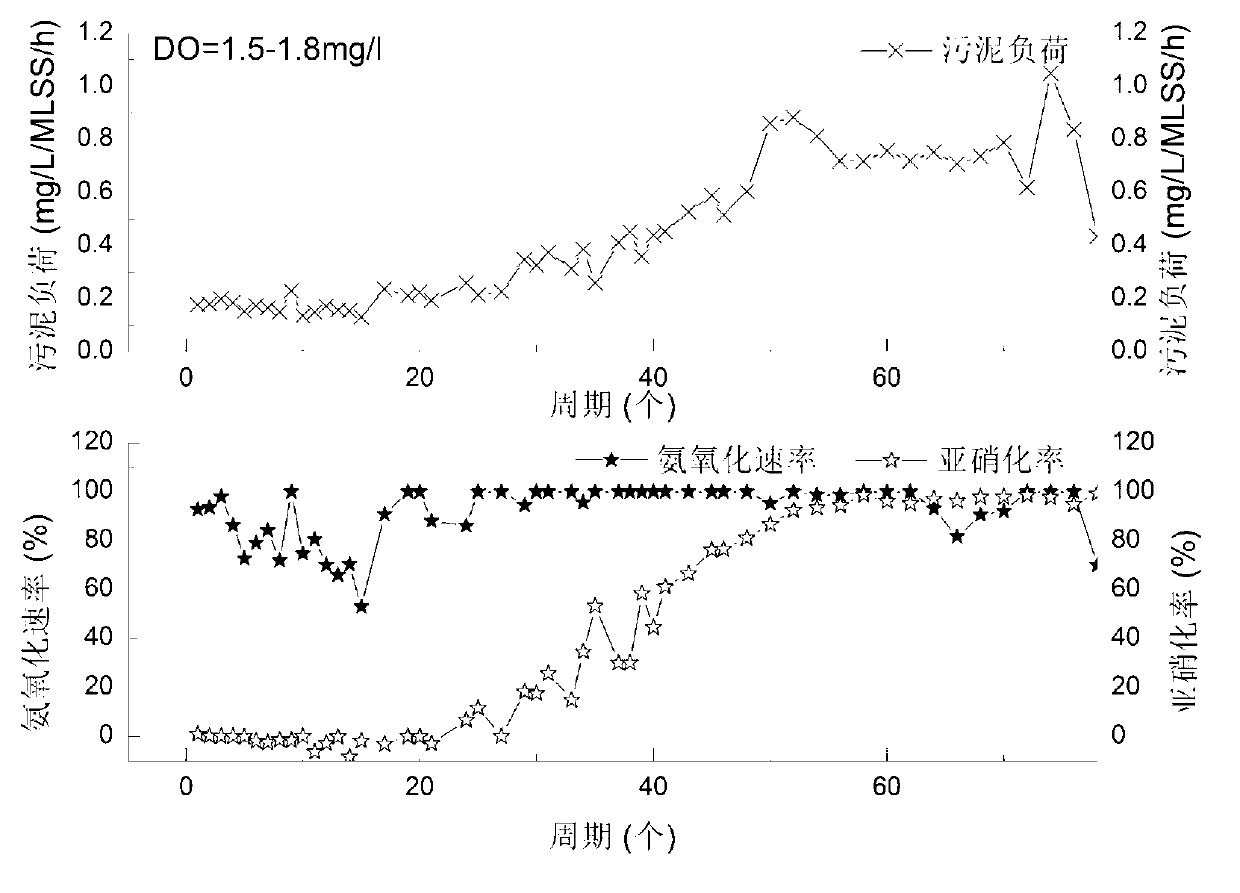

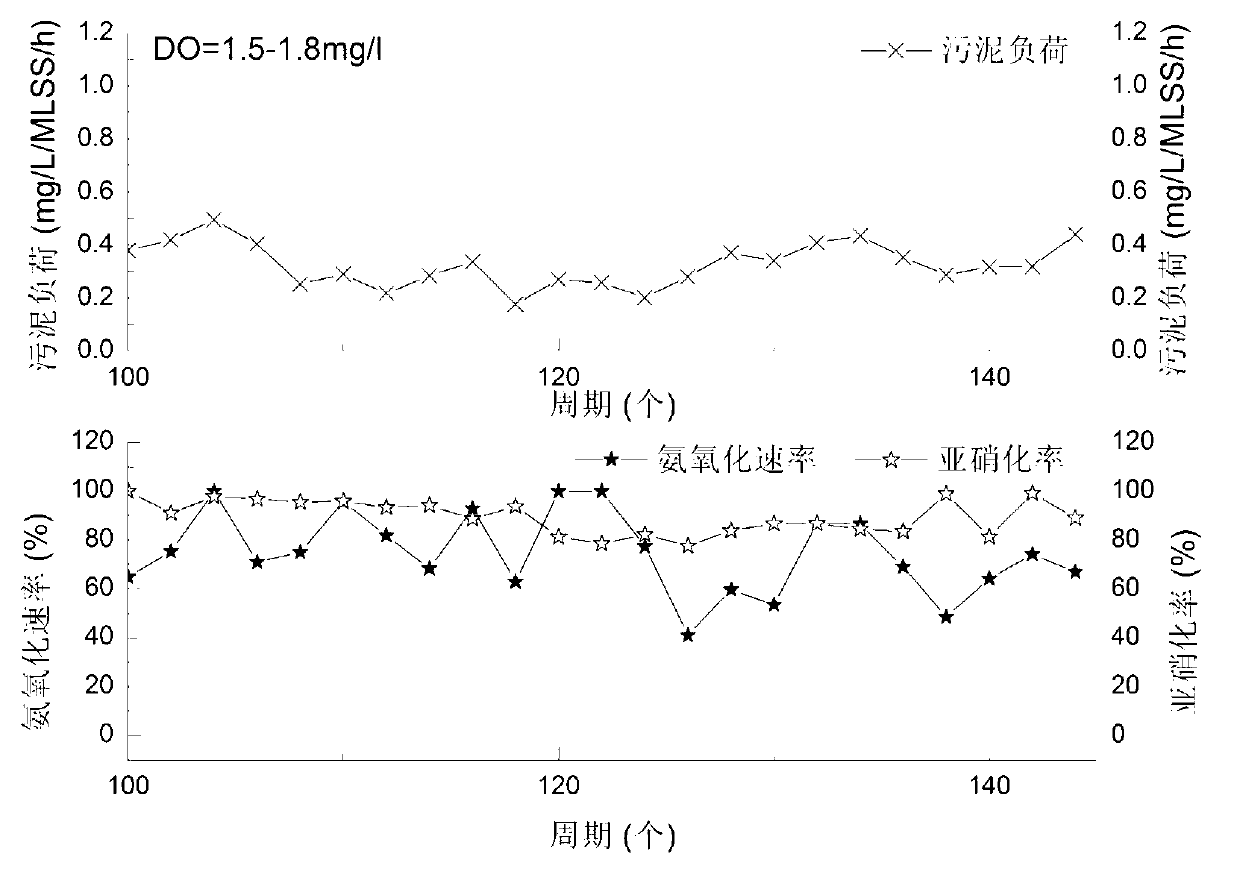

Non-oxygen limit starting method for nitrosoation of low-ammonia nitrogen sewage part

ActiveCN102992477AAchieve normal startupHigh ability to tolerate DOSustainable biological treatmentBiological water/sewage treatmentSludgeSewage

The invention discloses a non-oxygen limit starting method for nitrosoation of a low-ammonia nitrogen sewage part, belonging to the field of urban sewage treatment and reclamation. The non-oxygen limit starting method comprises the following steps: in an SBR (sequencing batch bioreactor), firstly inoculating nitrified sludge in an urban sewage plant, treating sewage with 120+ / -15mg / L of ammonia nitrogen under the condition that DO equals to 1.50-1.80mg / L, thereby realizing fast starting of nitrosoation within 25 days and achieving the nitrosoation rate by more than 90%; then reducing the concentration of the inlet ammonia nitrogen to be 35+ / -5mg / L which approaches the level of domestic sewage, and running under the condition of higher dissolved oxygen (DO equals to 1.20-1.50mg / L), thereby finally realizing the long-time and stable running of high dissolved oxygen (DO equals to 1.20-1.50mg / L) and low ammonia nitrogen sewage (35+ / -5mg / L) semi-nitrosoation and achieving the nitrosoation rate by more than 90%. According to the non-oxygen limit starting method, the difficulties that the low-ammonia nitrogen nitrosoation cannot be stably run for a long time and is low in treatment efficiency can be solved, the starting conditions are simple and fast, and the non-oxygen limit starting method has the advantages of higher sewage load, higher treatment efficiency, and the like.

Owner:BEIJING UNIV OF TECH

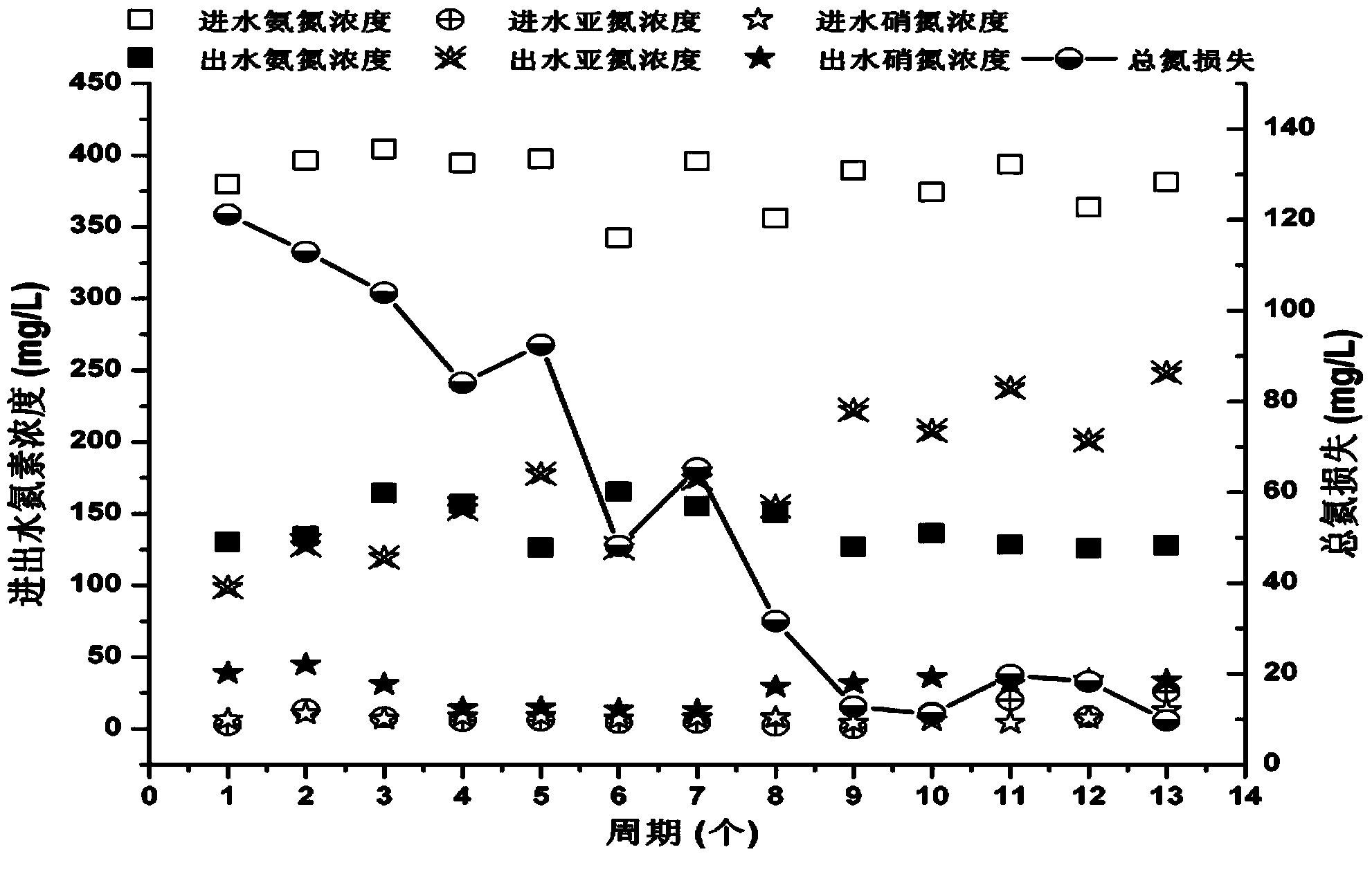

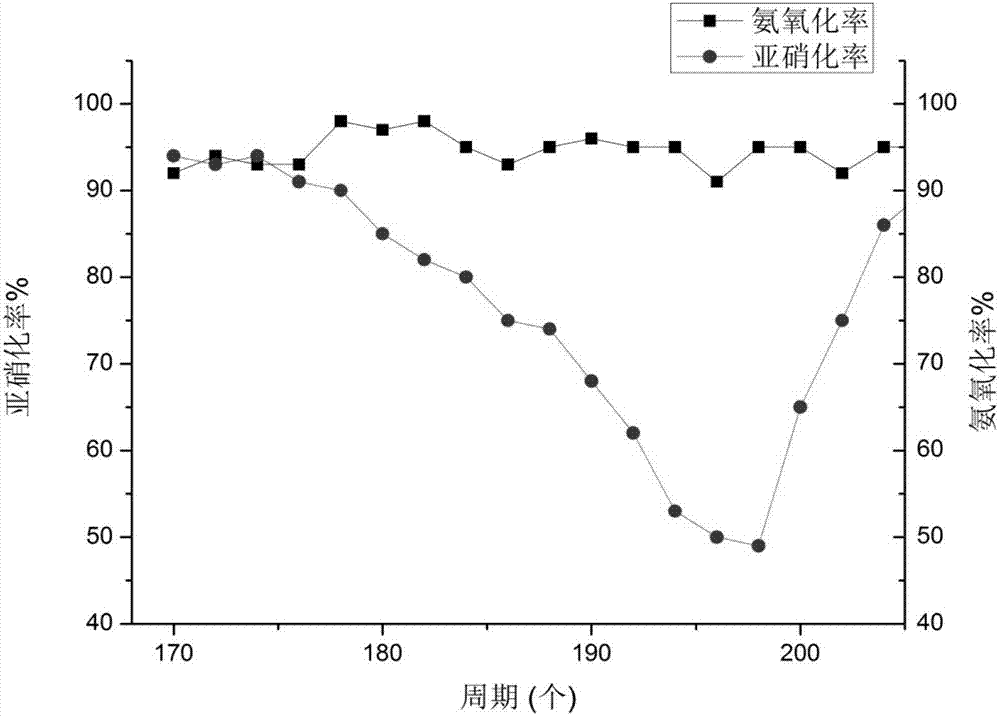

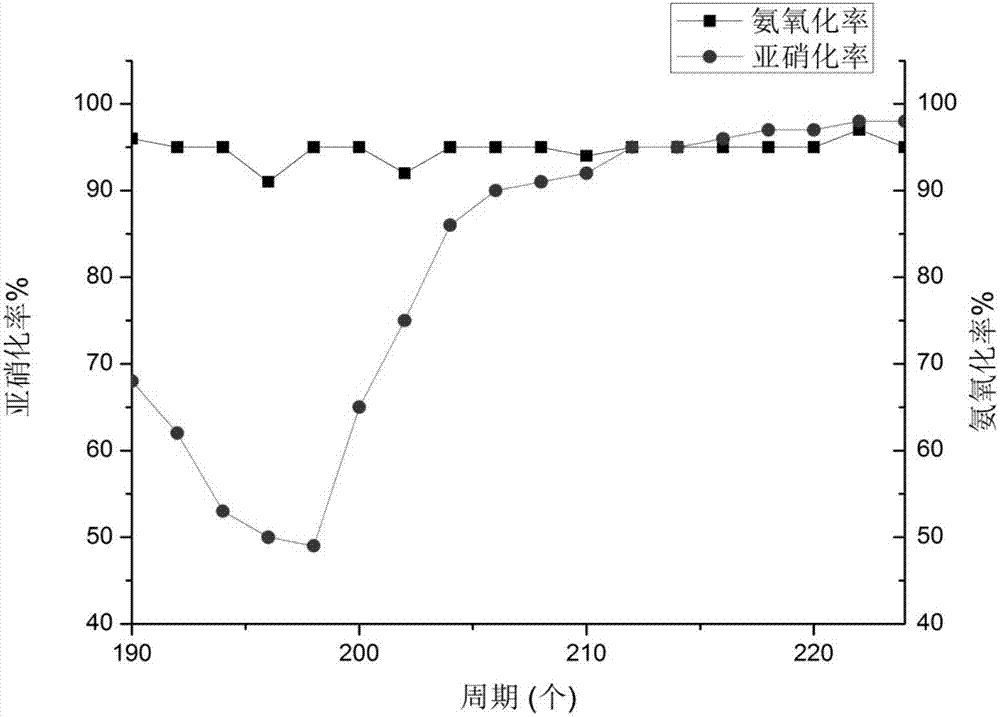

Rapid styrene butadiene rubber (SBR) nitrosoation recovery method

InactiveCN103086502APromote recoverySimple methodSustainable biological treatmentBiological water/sewage treatmentRecovery methodAeration rate

The invention discloses a rapid styrene butadiene rubber (SBR) nitrosoation recovery method and belongs to the fields of urban sewage treatment and resources. The sludge of which the long-term stable operation is damaged is arranged in an SBR reactor. The operation conditions are changed, the water inlet ammonia nitrogen concentration is 200-400 mg / L, the aeration rate is controlled, so that the dissolved oxygen is 1.0-2.0mg / L, the aeration time is controlled, the ammonia oxidation rate is controlled to be 90-99 percent, the pH is regulated to be 7.70-8.20, and the temperature is kept invariable. The rapid nitrosoation recovery is realized within four days in eight periods, and the nitrosoation rate is over 90 percent. The stable operation time reaches over seven days in 14 periods under the conditions, and the nitrosoation rate is always over 90 percent. The operating conditions are recovered to the original level, the water inlet ammonia nitrogen concentration is 50+ / -5mg / L, the nitrosoation rate can be maintained to be over 90 percent, and long-term stable operation of nitrosoation under the condition is realized. The problem that the nitrosoation is damaged and is slowly recovered for a long time is solved, and a technical guarantee is provided for realizing rapid recovery and stable operation for nitrosoation.

Owner:BEIJING UNIV OF TECH

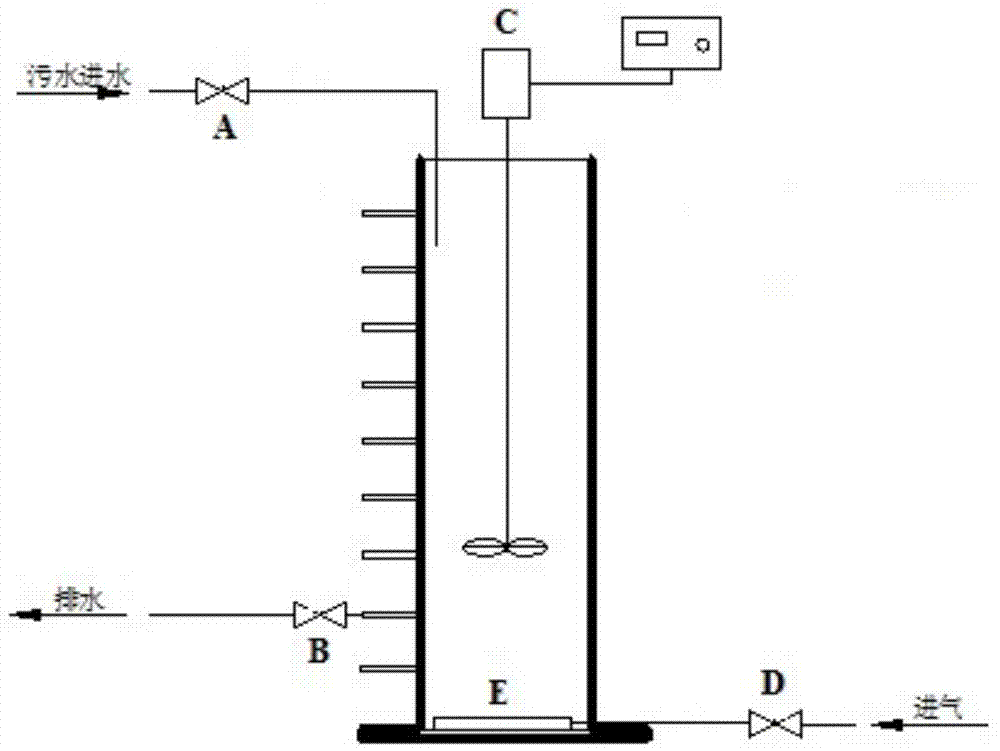

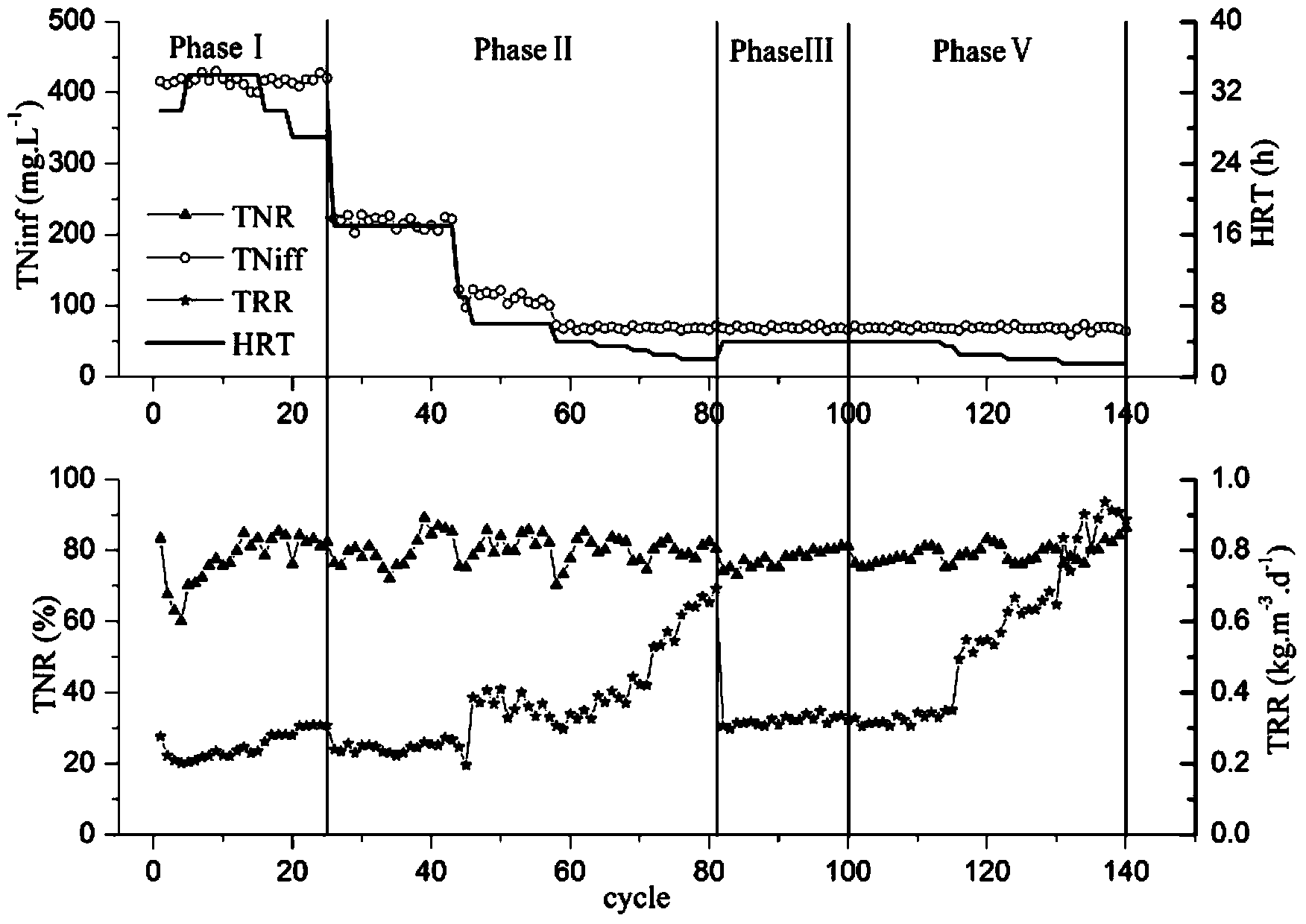

Completely autotrophic nitrogen removal over nitrite granular sludge starting method for treating urban domestic sewage

ActiveCN103723830AReal-time online monitoringThe solution to uneven mixing and even particle depositionTreatment with aerobic and anaerobic processesChemistryWater environment

The invention discloses a completely autotrophic nitrogen removal over nitrite granular sludge starting method specially used for treating urban domestic sewage, belonging to the field of water environment restoration and regeneration. Back-washed sludge of a completely autotrophic nitrogen removal over nitrite process biological filter column is inoculated, under the conditions of high temperature and high ammonia nitrogen, granular sludge is gradually cultivated under the action of mechanical agitation and aeration simultaneously, afterwards, the mass concentration of water distribution total nitrogen and reaction time are constantly reduced to enhance the cultivation of the granular sludge, and by changing the water quality, the treatment of the urban domestic sewage is finally achieved. After 140 cycles, the total nitrogen removal load reaches 0.9 kg?M<-3>?d<-1>, the sludge volume average particle size reaches 1052.49 mu m, and the urban domestic sewage with total nitrogen mass concentration being 65+ / -10 mg?L<-1> can be treated, so that the effluent quality meets the first class standard A; the completely autotrophic nitrogen removal over nitrite granular sludge starting method can be used for starting a reactor for cultivating sequencing batch type granular sludge for treating the urban domestic sewage.

Owner:BEIJING UNIV OF TECH

Treatment and reuse method of waste water in methanol-to-olefin process

ActiveCN102050548BEfficient use ofImprove water qualityChemical industryHydrocarbon from oxygen organic compoundsHigh concentrationFiltration

The invention relates to a treatment and reuse method of waste water in a methanol-to-olefin (MTO) process. The method comprises the following steps: (1) an effluent from an MTO reactor is subjected to the waste heat recovery through a waste heat boiler and then cooled and separated through a separation tower to generate high concentration MTO waste water; (2) the effluent from the MTO reactor isfurther cooled, a water phase is generated at the bottom of the separation tower, an olefin gas is generated at the top of the separation tower, and the olefin gas is further purified by compression and water scrubbing; (3) the water phase from the bottom of the separation tower and a water phase from bottom of a water scrubbing tower are treated by steam stripping, and a water phase generated atthe bottom of a steam stripping tower is cooled through a tower bottom heat exchanger to generate low concentration MTO water; (4) the low concentration MTO water is homogenized; (5) the low concentration MTO water is subjected to the coagulating sedimentation treatment after the homogenization; (6) the low concentration MTO water is subjected to the aerobic aeration treatment after the coagulating sedimentation treatment; (7) the effluent water is settled after the aerobic aeration treatment; and (8) the effluent water is subjected to the flocculation filtration treatment after the settlement. The method can not only reduce the consumption of the fresh water in the MTO production, but also reduce the discharge of pollutants to the environment in the MTO production.

Owner:CHINA PETROLEUM & CHEM CORP +1

SBR nitrosation starting method suitable for municipal household sewage

InactiveCN103102008ALow running costRealize the purpose of starting nitrosationSustainable biological treatmentBiological water/sewage treatmentResearch ObjectMunicipal sewage

An SBR nitrosation starting method suitable for municipal household sewage belongs to the field of treatment and resource of municipal sewage. Complete nitrification sludge is inoculated under normal temperature conditions, and municipal household sewage is the research object. In an initial sludge acclimatization, first the concentration of DO is controlled at 0.8-1.0 mg / L for running of 10d (20 cycles), so that AOB and NOB can be rapidly proliferated; from the 11th day, oxygen is limited, and concentration of DO is controlled to 0.3-0.5mg / L, and ammonia oxidation rate is controlled at around 50%. After 44 days, nitrosation rate reaches higher than 90%, and COD removal rate reaches higher than 80%, so as to successfully realize SBR nitrification start-up of household sewage at normal temperature.

Owner:BEIJING UNIV OF TECH

Rose-flower-containing traditional Chinese medicine composition for treating diabetes

ActiveCN105106577AReduce dosageLow toxicityMetabolism disorderBird material medical ingredientsRose flowerChinese herbology

The invention belongs to the technical field of traditional Chinese medicines, and particularly relates to rose-flower-containing traditional Chinese medicine composition for treating diabetes. The traditional Chinese medicine composition comprises raw materials as follows: milkvetch roots, yams, common anemarrhena rhizomes, kudzuvine roots, Chinese magnoliavine fruits, snakegourd roots, chicken's gizzard membranes and rose flowers. When the traditional Chinese medicine composition is used for treating Caenorhabditis elegans diabetes models, results indicate that the traditional Chinese medicine composition can significantly reduce dauer phenotypes of diabetes Caenorhabditis elegans and can be applied to preparation of drugs for treating the diabetes.

Owner:GANSU DONGFANG TIANRUN ROSE TECH DEV CO LTD

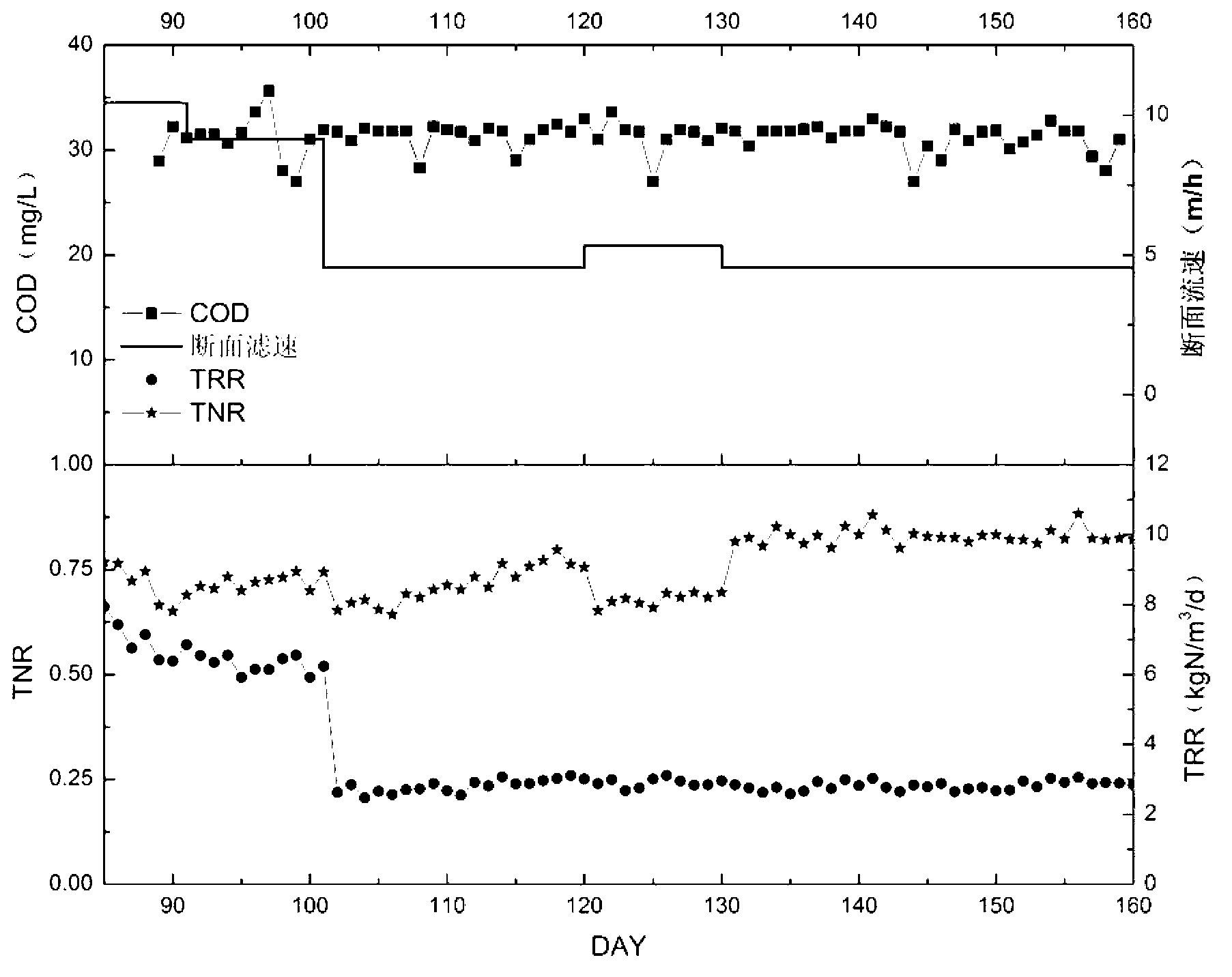

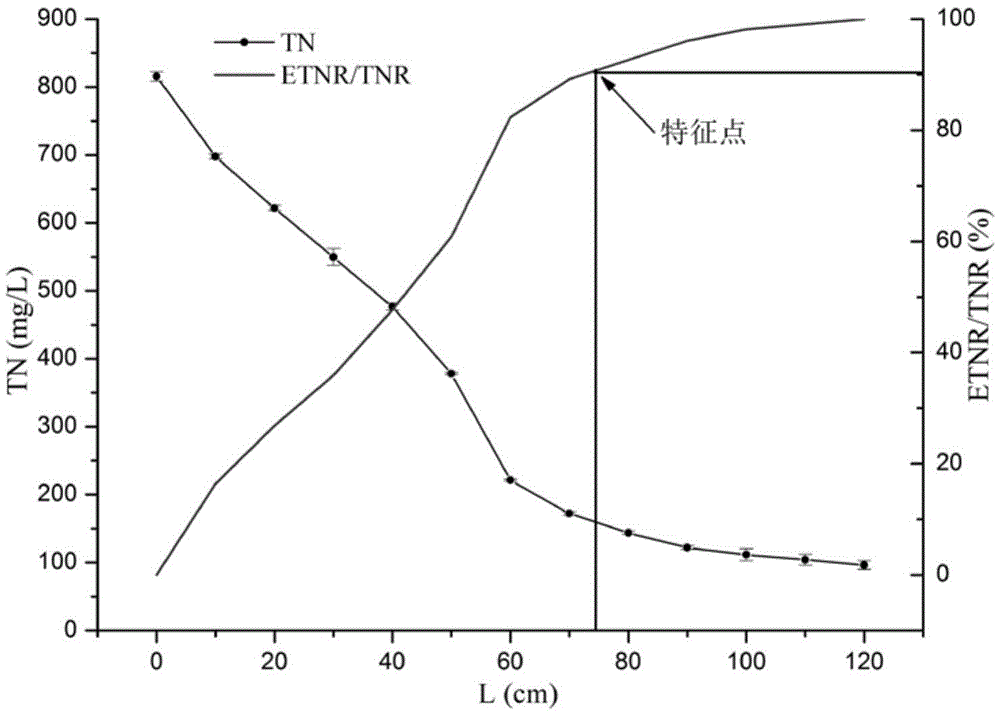

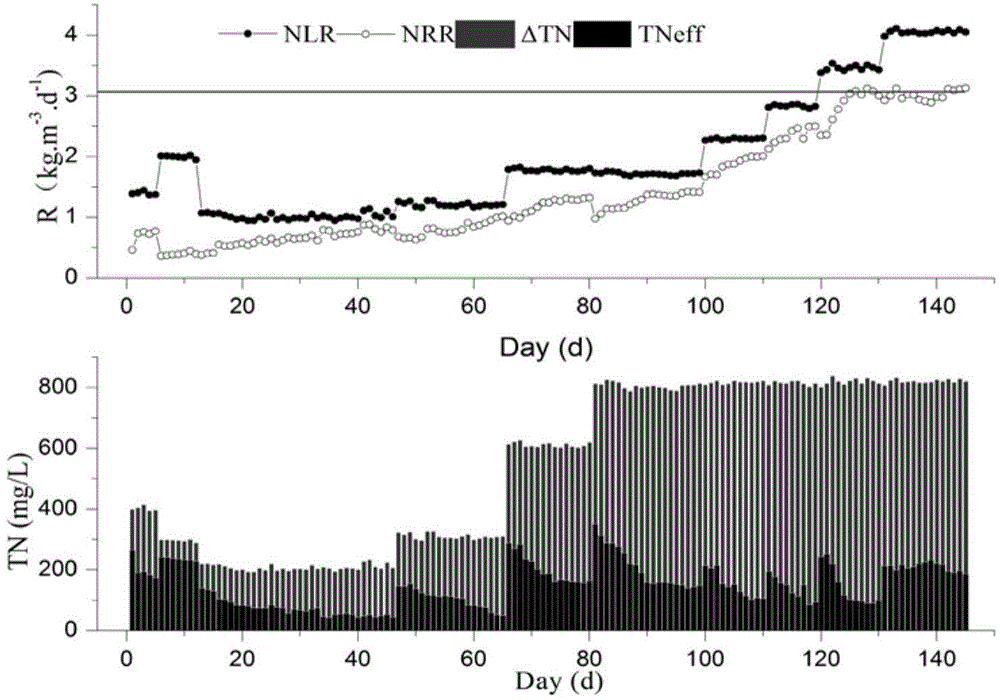

Starting and efficient operating method of normal-temperature high-ammonia-nitrogen completely autotrophic nitrogen-removal over nitrite (CANON) technique

ActiveCN103601297AIncreased success rate of attachmentThe scope of protection is not limitedTreatment with aerobic and anaerobic processesNitrogen removalBiofilm

The invention relates to a starting and efficient operating method of a normal-temperature high-ammonia-nitrogen completely autotrophic nitrogen-removal over nitrite (CANON) technique, belonging to the field of aquatic environment restoration and regeneration. CANON filter column back flush sludge is inoculated to a reactor, and a biofilm formation stage, a variable substrate starting stage and an efficient operating stage are performed at normal temperature to achieve the level of treating 780-820 mg / L high-ammonia-nitrogen sewage within 150 days; and the average total nitrogen removal load is up to 3.03kg.m<-3>.d<-1>, which is many times higher than the Japanese Furukawa (0.83kg.m<-3>.d<-1>) and Spanish Vazquez-Padin (0.5kg.m<-3>.d<-1>).

Owner:BEIJING UNIV OF TECH

Preparation method of nano clay reinforced carbon/carbon composite

The invention discloses a preparation method of nano clay reinforced carbon / carbon composite, which comprises the steps of dispersing clay and asphalt in dispersant-containing water for stirring to prepare uniform dispersion liquid, immersing continuous carbon fiber in the dispersion liquid and then naturally airing or drying at low temperature to prepare a composite prefabricated part, and stacking the prefabricated part for hot pressing to obtain the nano clay reinforced carbon / carbon composite. The preparation method has the advantages of low cost, simplicity, rapidness and high preparation strength.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com