Method for regulating and controlling nitrogen proportion of partial nitrosation effluent of low-ammonia-nitrogen continuous stirred-tank reactor (CSTR) at normal temperature

A technology of nitrous nitrogen and low ammonia nitrogen, which is applied in the field of urban sewage treatment and resource utilization, can solve the problem that the accumulation effect of nitrite nitrogen is difficult to maintain stably, and achieve the effect of saving aeration and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

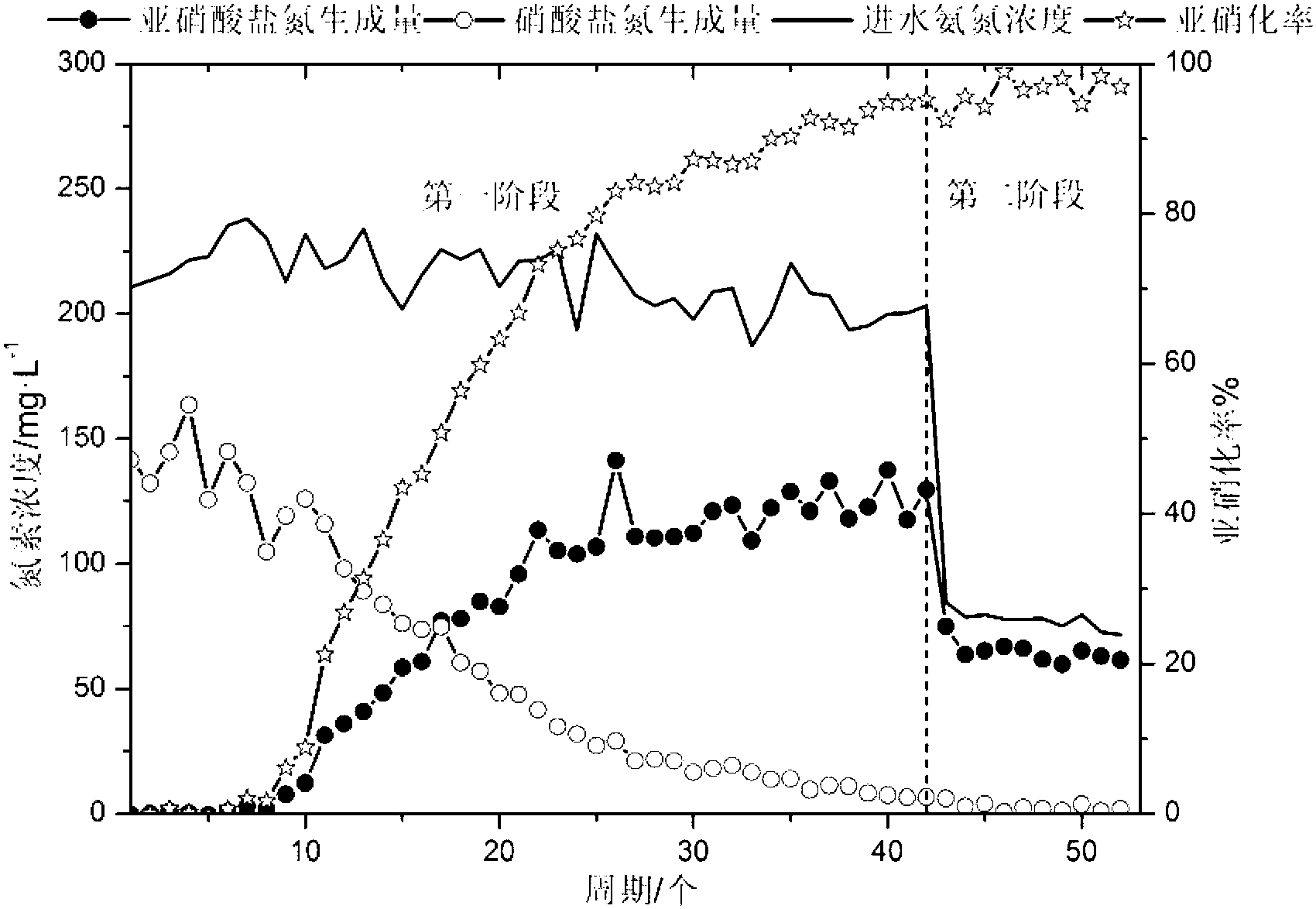

[0037] like figure 2 As shown, according to the second step, the initial nitrification performance of the sludge is better, and the ammonia nitrogen oxidation load is 0.2kgN / kgMLSS / d. Directly enter the second stage, control the initial ammonia nitrogen concentration at 187.0~238.0mg / L, pH at 7.80, and DO in the reactor at 0.40mg / L. Ensure that the concentration of ammonia nitrogen in the effluent is 70.0 mg / L. According to the periodic test, the aeration time is determined to be 8 hours, with 2 cycles per day. After 34 cycles, the nitrosation rate reaches more than 90%, and then runs for 7 cycles, and the nitrosation rate is above 90%. The nitrosation reactor started successfully and entered the third stage. The concentration of ammonia nitrogen in the influent is controlled at 71.7~84.6mg / L, and the aeration time is determined to be 5 hours according to the periodic test. It runs 2 cycles a day for 10 days. The nitrification rate is above 90%, and the operation mode can be...

Embodiment 2

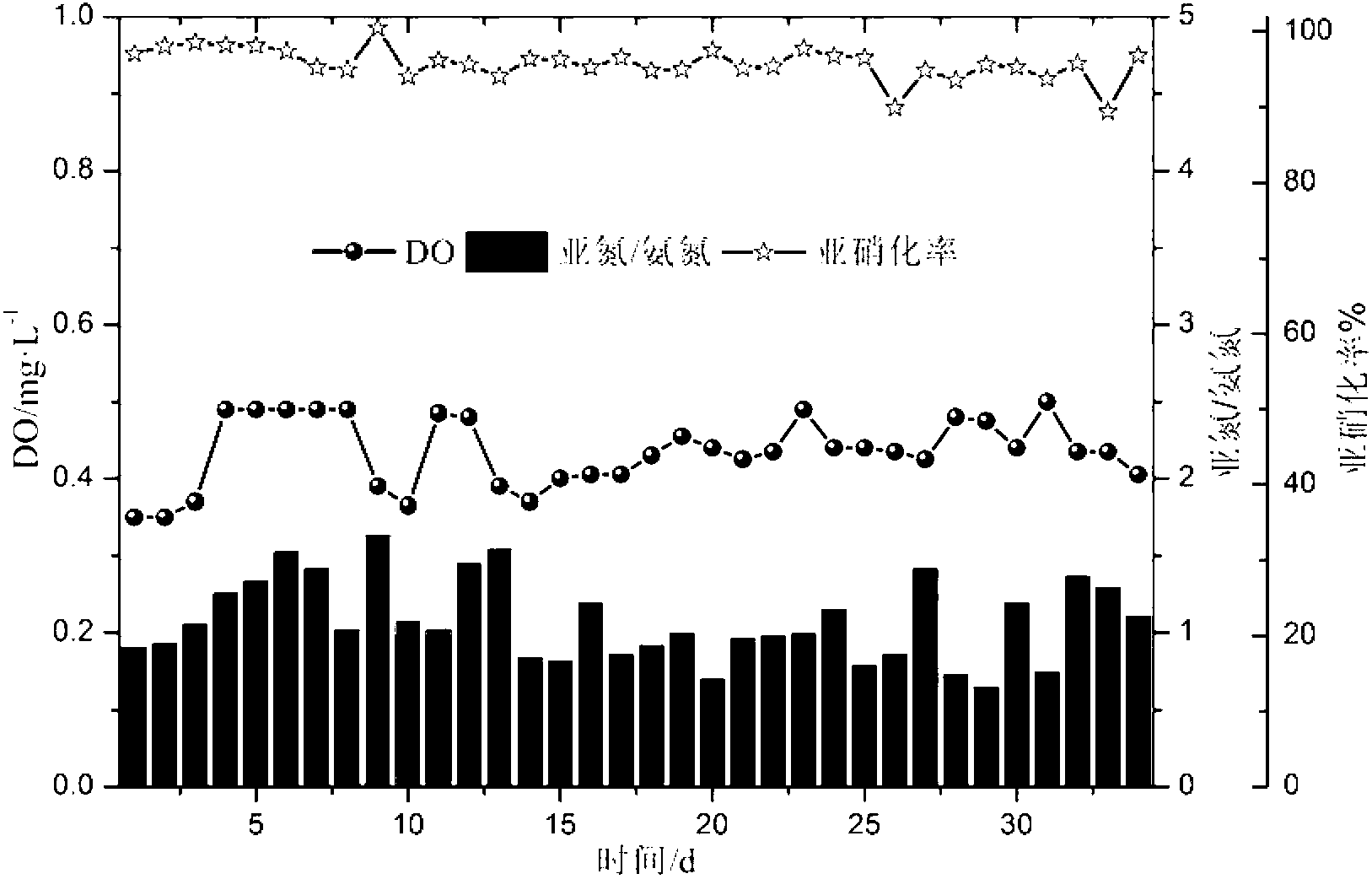

[0039] like image 3 As shown, the ammonia nitrogen conversion load of the SBR low ammonia nitrogen operation period is 0.2kgN / kgMLSS / d, based on this value, when the influent NH 4 + When -N is 75.0mg / L, the amount of ammonia nitrogen removal is set at 38mg / L, V=30L, the initial HRT is 3.0h, and the DO concentration is 0.35mg / L. According to step 3, when the DO is 0.35mg / L on the first and second day, the water effluent NO 2 - -N / NH 4 + -N2 - -N / NH 4 + -N is between 1~1.32:1. And when the DO concentration was 0.39mg / L on the 9th day, the effluent ratio was 1.63>1.32, so the DO concentration should be reduced. Run for 34d at HRT=3.0h, NO 2 - -N / NH 4 + -N is between 1~1.32:1 for longer than 7d, it is considered that the water is NO 2 - -N / NH 4 + -N is regulated successfully, and the effluent NO is determined 2 - -N / NH 4 + When -N is between 1~1.32:1, the corresponding DO / ALR is 0.75mgO 2 / gNd2 / g N d, to ensure that the average nitrosation rate at this stag...

Embodiment 3

[0041] like Figure 4 As shown, in order to increase the ammonia nitrogen oxidation load of the reactor, the constant DO / ALR value is still controlled at 0.75mgO 2 / g N d, according to step 4, HRT is reduced from 3.0h in the previous stage to 2.5h. Adopting the DO concentration adjustment method in Step 3, the average effluent ratio was 1.04 on the 53rd to 62d. It is considered that the regulation of the effluent ratio was successful and the ammonia nitrogen conversion load reached 0.27kgN / (kgMLSS·d) at this stage. Continue to increase the ammonia nitrogen oxidation load of the reactor, the HRT is reduced to 1.5h, and the DO concentration adjustment method of step 3 is still adopted. From the 88th day to the 98th day, the average value of the effluent ratio was 1.18. It was considered that the regulation of the effluent ratio was successful, and the ammonia nitrogen conversion load reached 0.54 kgN / (kgMLSS·d) at this stage.

[0042] When the HRT is 3.0h, 2.5h and 1.5h, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com