Slow controlled release fertilizer coating agent

A slow and controlled release fertilizer and coating agent technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of air permeability, water permeability decrease, residual components polluting the soil environment, long degradation cycle, etc., to improve crop yield and quality, improve the stress resistance function, and improve the effect of fertilizer efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

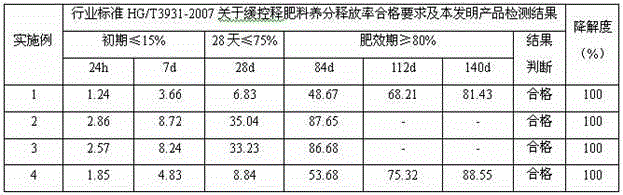

Examples

Embodiment 1

[0028] The slow and controlled release fertilizer coating agent described in this embodiment is made from the following raw materials, each raw material and weight percentage are: 75% of montan wax resin, 4% of sodium fulvic acid, 6% of potassium fulvic acid, 10% of methyl acetate , lignite essence 5%, the mass percentage sum of all raw materials is 100%.

[0029] The preparation method of the slow and controlled release fertilizer coating agent described in the present embodiment comprises the following steps:

[0030] (1) Put 750kg of montan wax resin and 100kg of methyl acetate into the reactor I according to the weight ratio, heat up to 40°C, and stir under normal pressure for 10 minutes to obtain the preparatory solution I;

[0031] (2) Put 40kg of sodium fulvic acid, 60kg of potassium fulvic acid and 50kg of lignite essence into the reaction kettle II according to the weight ratio, heat up to 50°C, and stir for 10 minutes under normal pressure to obtain the...

Embodiment 2

[0035] Example 2: The slow and controlled release fertilizer coating agent described in this embodiment is made from the following raw materials, and the raw materials and weight percentages are: 40% of montan wax resin, 20% of sodium brown humate, 20% of potassium brown humate, ethyl acetate 5%, lignite essence 15%, the weight percentage sum of all raw materials is 100%.

[0036] The preparation method of the slow and controlled release fertilizer coating agent described in the present embodiment comprises the following steps:

[0037] (1) Put 400kg of montan wax resin and 50kg of ethyl acetate into the reaction kettle I according to the weight ratio, heat up to 60°C, stir for 5 minutes under normal pressure, and obtain the preparatory solution I;

[0038](2) Put 200kg of sodium brown humate, 200kg of potassium brown humate and 150kg of lignite essence into the reaction kettle II according to the weight ratio, heat up to 60°C, and stir for 5 minutes under normal pres...

Embodiment 3

[0042] Example 3: The slow and controlled release fertilizer coating agent described in this embodiment is made from the following raw materials, and the raw materials and weight percentages are: 42% of montan wax resin, 15% of sodium brown humic acid, 5% of ammonium brown humic acid, and 5% of brown humic acid Potassium 10%, propyl acetate 8%, lignite essence 20%, the weight percentage sum of all raw materials is 100%.

[0043] The preparation method of the slow and controlled release fertilizer coating agent described in the present embodiment comprises the following steps:

[0044] (1) Put 420kg of montan wax resin and 80kg of propyl acetate into the reaction kettle I according to the weight ratio, heat up to 50°C, stir under normal pressure for 8 minutes, and obtain the preparatory solution I;

[0045] (2) Put 150kg of sodium brown humate, 50kg of ammonium brown humate, 100kg of potassium brown humate and 200kg of lignite essence into the reactor II according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com