Polymorphic controlled-release fertilizer and preparation method thereof

A controlled-release fertilizer and multi-form technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problem of crop controlled-release fertilizers being greatly affected by soil moisture, temperature, and soil quality, and the peak value of fertilizer release The control point is difficult to grasp and other problems, and the expected release target is good, it is conducive to full absorption, and the effect of low biuret content is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

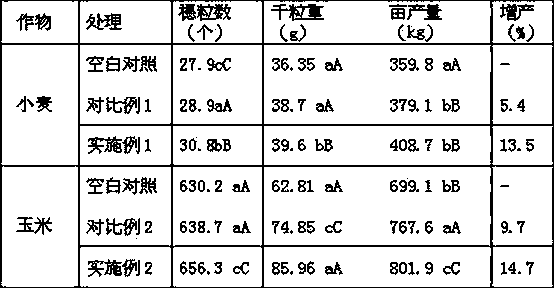

Embodiment 1

[0065] Example 1: Preparation of polymorphic wheat controlled release fertilizer, 24-12-12.

[0066] Raw material component parts by weight are as follows:

[0067] 40 parts of urea,

[0068] 8 parts of ammonium nitrate,

[0069] 3 parts of formaldehyde,

[0070] Potassium sulfate 24 parts,

[0071] 23 parts of monoammonium phosphate,

[0072] 2 parts of medium and micro fertilizer.

[0073] Preparation:

[0074] 1. Mix 40 parts of urea and 8 parts of ammonium phosphorus nitrate at the bottom of the tower and then add them to the melting tank, add melting agent and viscosity reducing agent into the melting tank, the molten slurry enters the buffer tank, and part of it is sent to phosphoric acid after metering In the ammonium mixing tank, a part of the urea-formaldehyde removal reaction pump inlet.

[0075] 2. At the inlet of the urea-formaldehyde reaction pump, under the action of the melting agent and the viscosity reducing agent, add formaldehyde vapor with a mass fr...

Embodiment 2

[0078] Example 2: Preparation of Polymorphic Corn Controlled Release Fertilizer, 20-10-15.

[0079] Raw material component parts by weight are as follows:

[0080] 30 parts of urea,

[0081] 10 parts of ammonium nitrate,

[0082] 3 parts of formaldehyde,

[0083] Ammonium sulfate 5 parts,

[0084] Potassium sulfate 30 parts,

[0085] 19 parts of monoammonium phosphate,

[0086] 3 parts of medium and micro fertilizer.

[0087] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com