Rapid styrene butadiene rubber (SBR) nitrosoation recovery method

A rapid recovery and nitrosation technology, applied in the field of urban sewage treatment and resource utilization, can solve the problems of decreased nitrosation rate, deterioration of nitrosation, inability to provide stable effluent, etc., and achieves the effect of simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

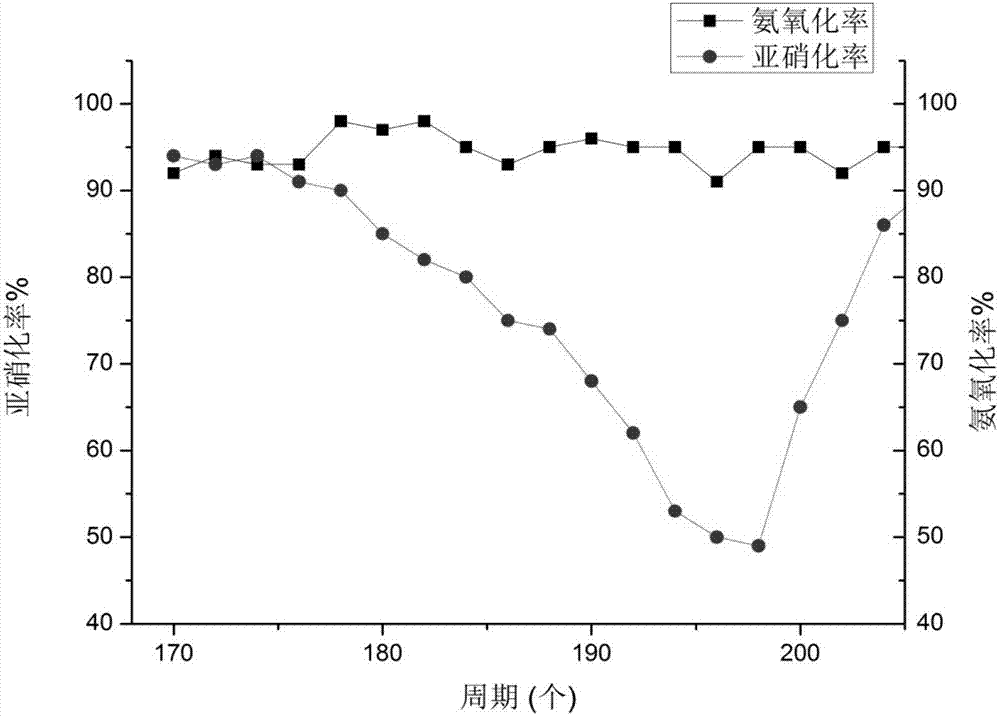

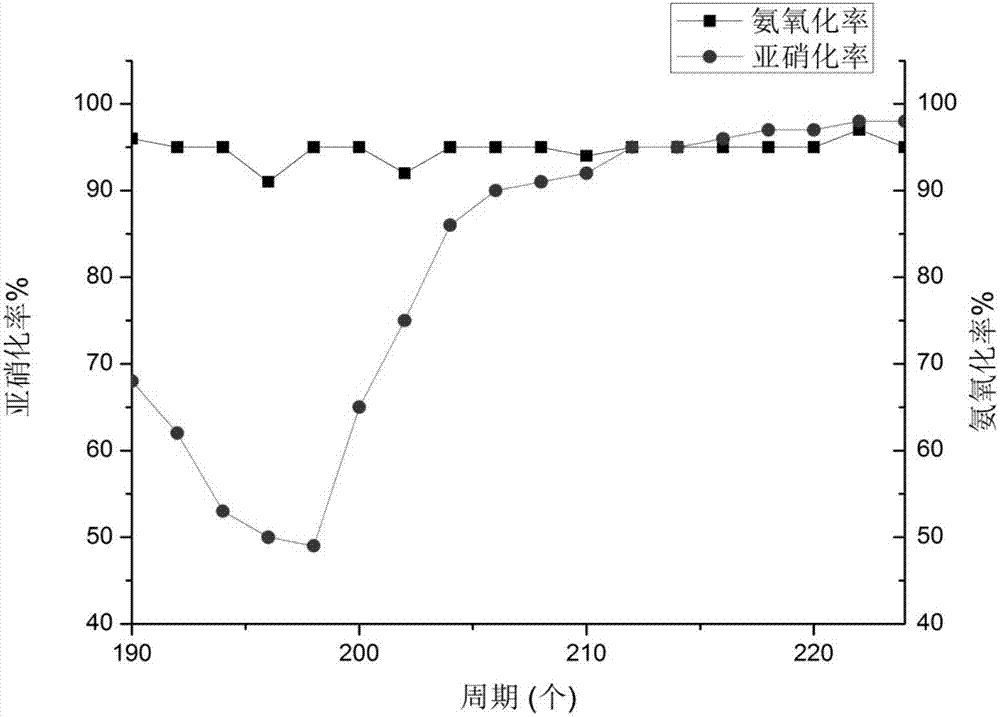

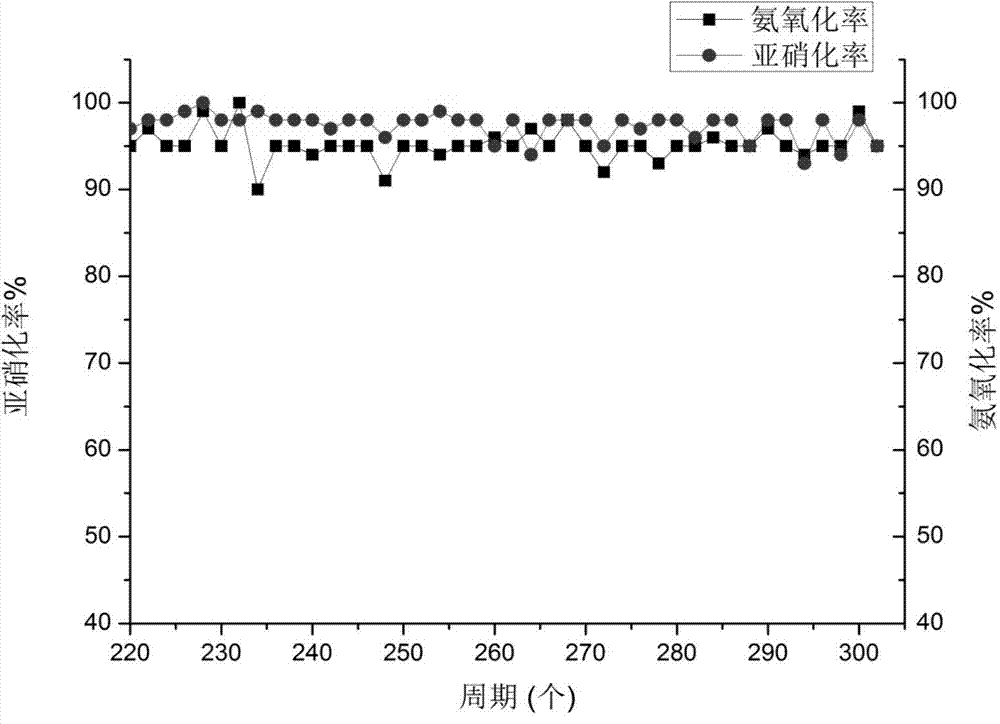

[0016] The test is based on simulated sewage water, and the specific water quality is as follows:

[0017] Influent water quality before and after restoration: NH 4 + -N=50±5mg / L, pH=7.70~8.20, temperature 25±1℃.

[0018] Influent water quality in recovery stage: NH 4 + -N=200-400mg / L, pH=7.70~8.20, temperature 25±1℃.

[0019] Specific steps are as follows:

[0020] Step 1: Reactor Construction

[0021] The reactor adopts SBR reactor, and the reactor is equipped with an aeration device, which can control the concentration of dissolved oxygen in the reactor wastewater by adjusting the amount of aeration. The reactor is equipped with a simple automatic control device to realize automatic water intake, reaction, precipitation and drainage processes.

[0022] Step 2: Change operating conditions

[0023] Connect the nitrosated sludge that has been destroyed by long-term operation to the SBR reactor, change the operating conditions, the concentration of ammonia nitrogen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com