SBR nitrosation starting method suitable for municipal household sewage

A technology of urban domestic sewage and nitrosation, applied in the field of urban domestic sewage SBR nitrosation start-up, can solve problems such as unstable operation, and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The test is based on the domestic sewage of a community, and the specific water quality is as follows: COD=300-400mg / L, BOD 5 =120-150mg / L, SS=76-114mg / L, TP=5.75-6.30mg / L, NH 4 + -N=75-90mg / L, NO 2 - -N≤0.25mg / L, NO 3 - -N≤1.5mg / L, TP≤1mg / L, pH=7.0-7.8, alkalinity is 550.59-610.78mg / L (as CaCO 3 count).

[0022] The specific treatment is as follows:

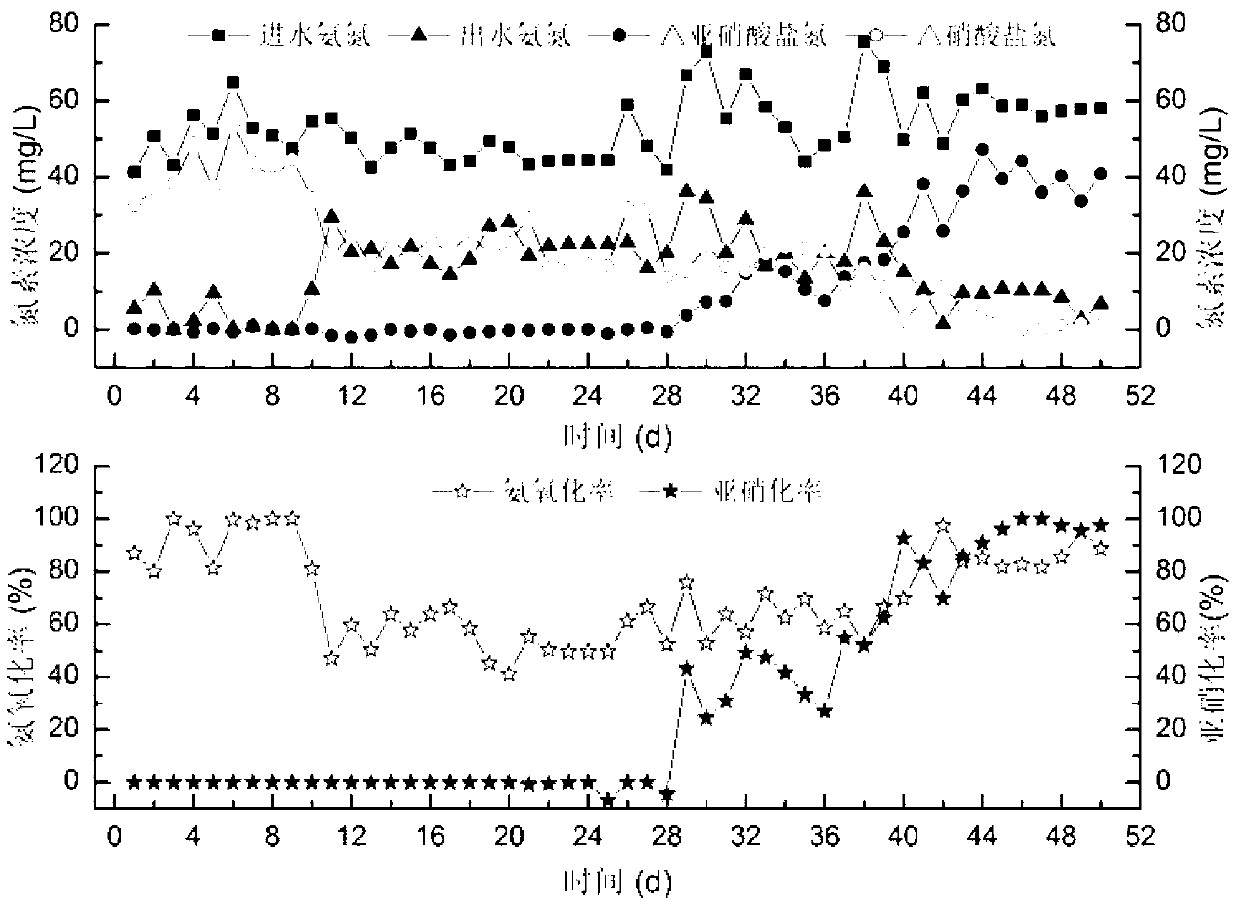

[0023] In the initial sludge acclimatization, first control the DO concentration at 0.8-1.0mg / L and run for 10 days (20 cycles), so that both AOB and NOB can rapidly proliferate. From the 11th day, start to limit oxygen and control the DO concentration to 0.3 -0.5mg / L, and the ammonia oxidation rate is controlled at about 50%, and the dual control of low DO and ammonia oxidation rate is used to enrich AOB and eliminate NOB. figure 1 It is the change trend diagram of nitrogen concentration, ammonia oxidation rate and nitrosation rate in the start-up stage.

[0024] Depend on figure 1 It can be seen that in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com