Method and device for sheet selection or plate falling at cold end of flat plate glass production line

A flat glass and production line technology, applied in glass production, glass manufacturing equipment, glass transportation equipment, etc., can solve problems such as unstable transmission, uneven glass chips, affecting the surface quality of glass finished products and packaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

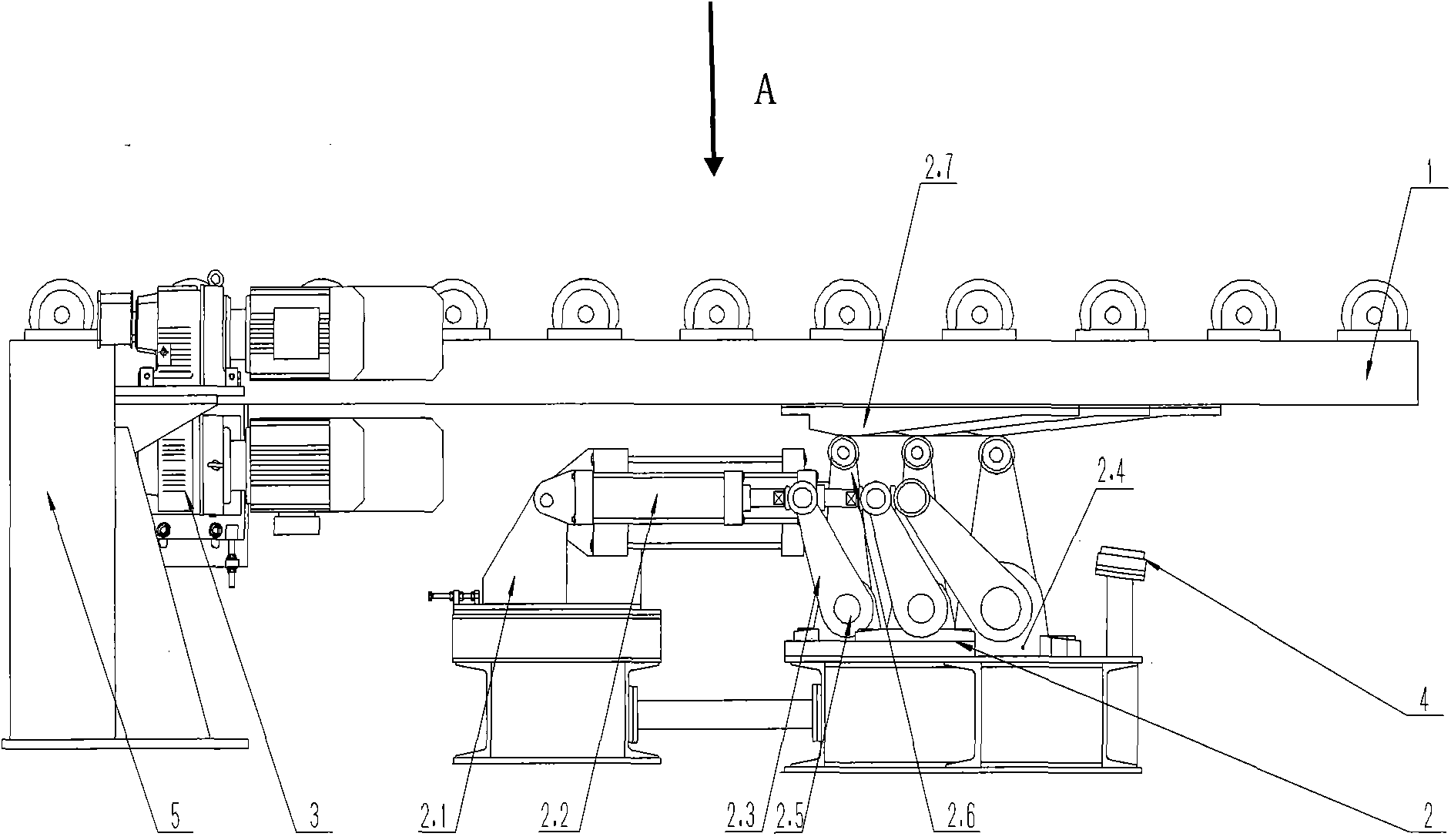

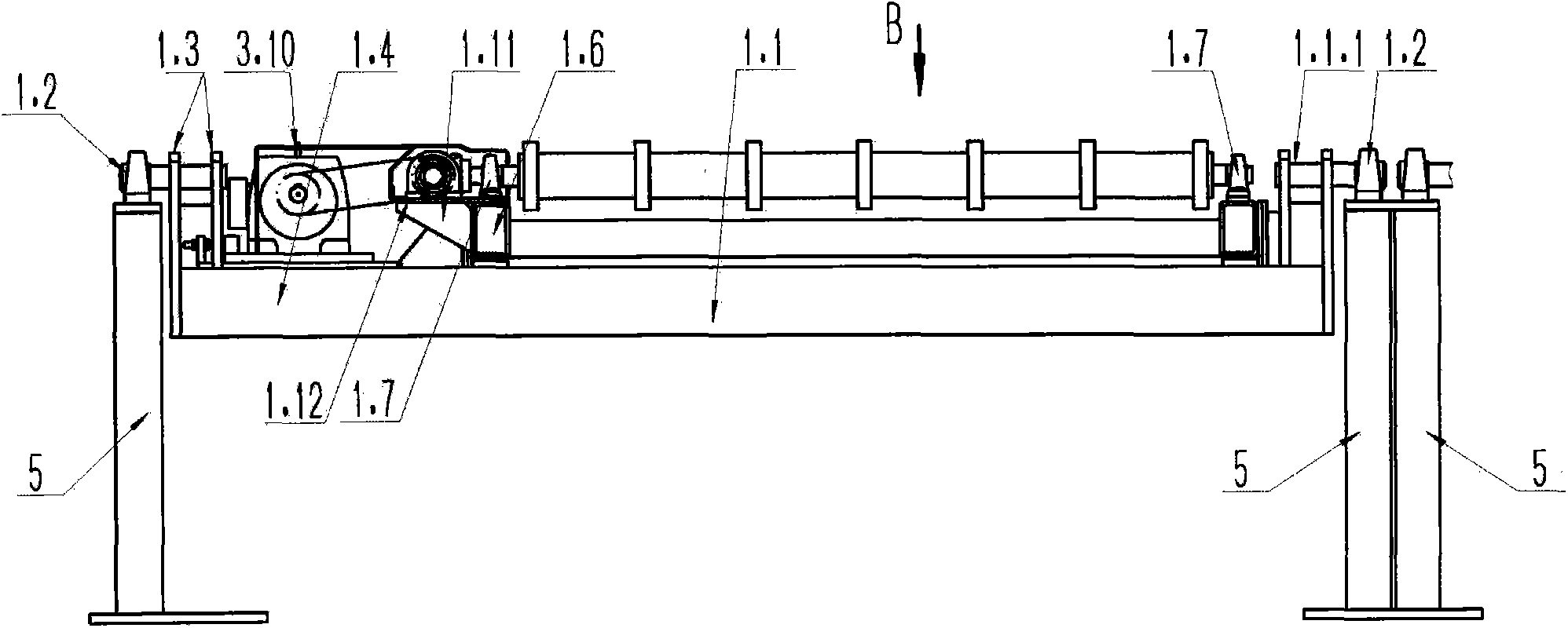

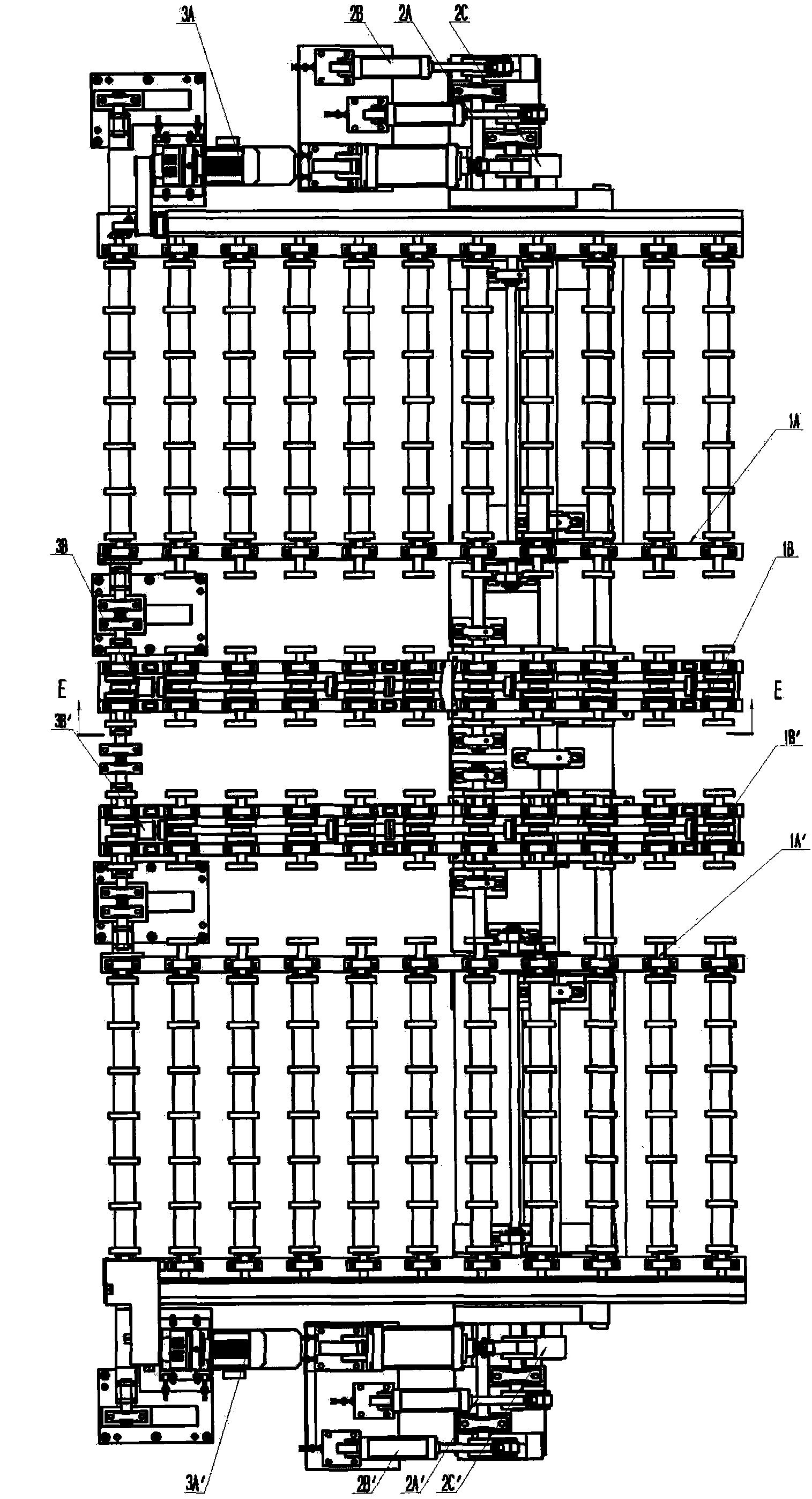

[0035] The invention provides a flat glass production line, mainly a cold end device of a float glass production line, and provides a method for realizing glass selection and dropping by using the device.

[0036] Including suspension roller table, transmission mechanism, lifting mechanism and control system. The device is composed of 4 sets of independent suspension roller tables. The 4 sets of suspension roller tables are placed in parallel, with the head and tail at the same height. The upper busbars of the horizontal roller tables are all on the same plane. Each set of suspension roller tables includes a rectangular frame and a crankshaft respectively, and one end of the rectangular frame lengthwise of the suspension roller table is connected to the crankshaft connected to it and a support perpendicular to the ground; the other end of the suspension roller table lengthwise is a suspended cantilever end; Among them, the rectangular frame is welded by 2 longitudinal beams and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com