Integrated biogas treatment system

A treatment system and integrated technology, applied in the field of biogas treatment systems, can solve the problems of low integration, low biogas combustion efficiency, and unsuitability for biogas generator sets to generate electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

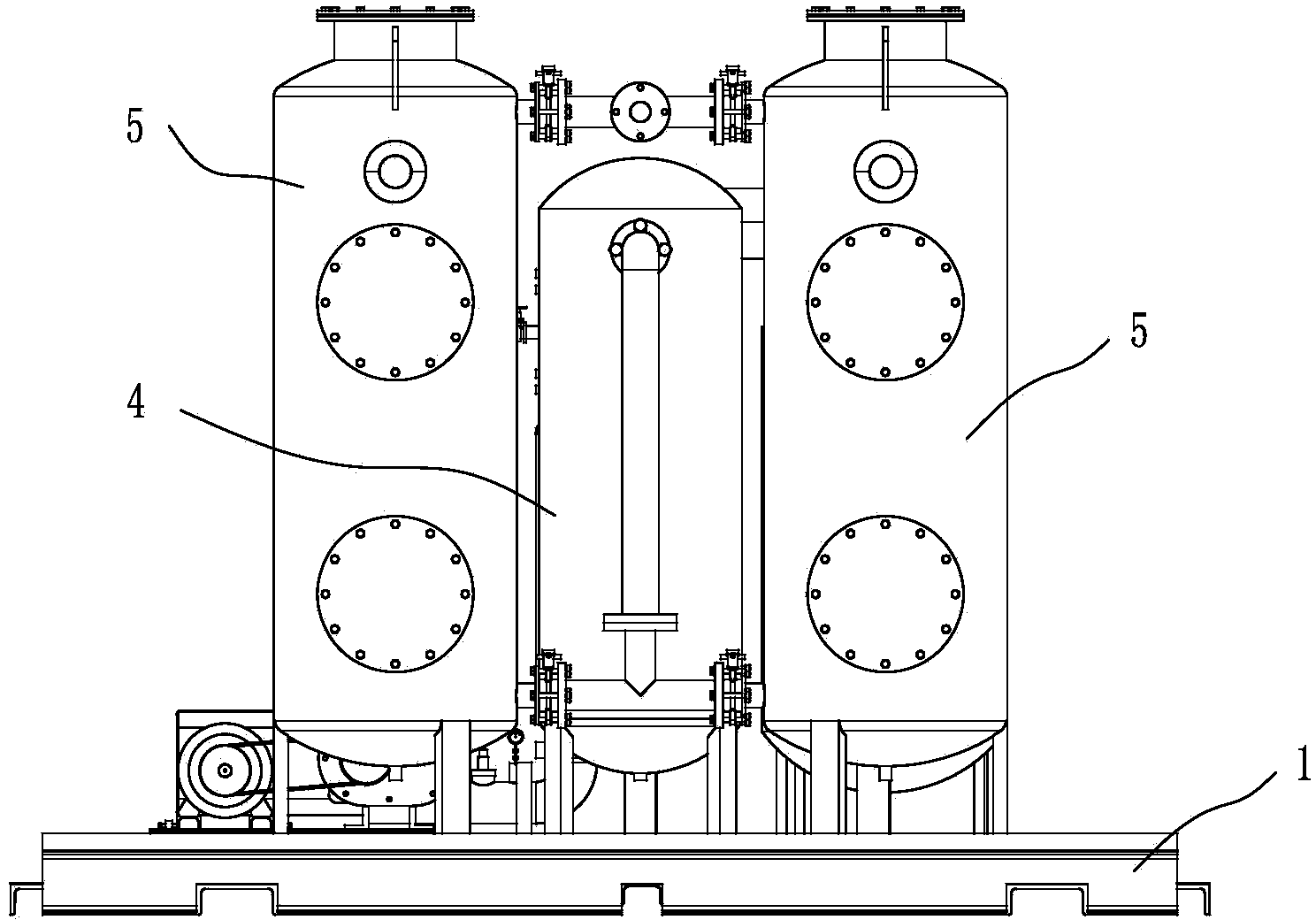

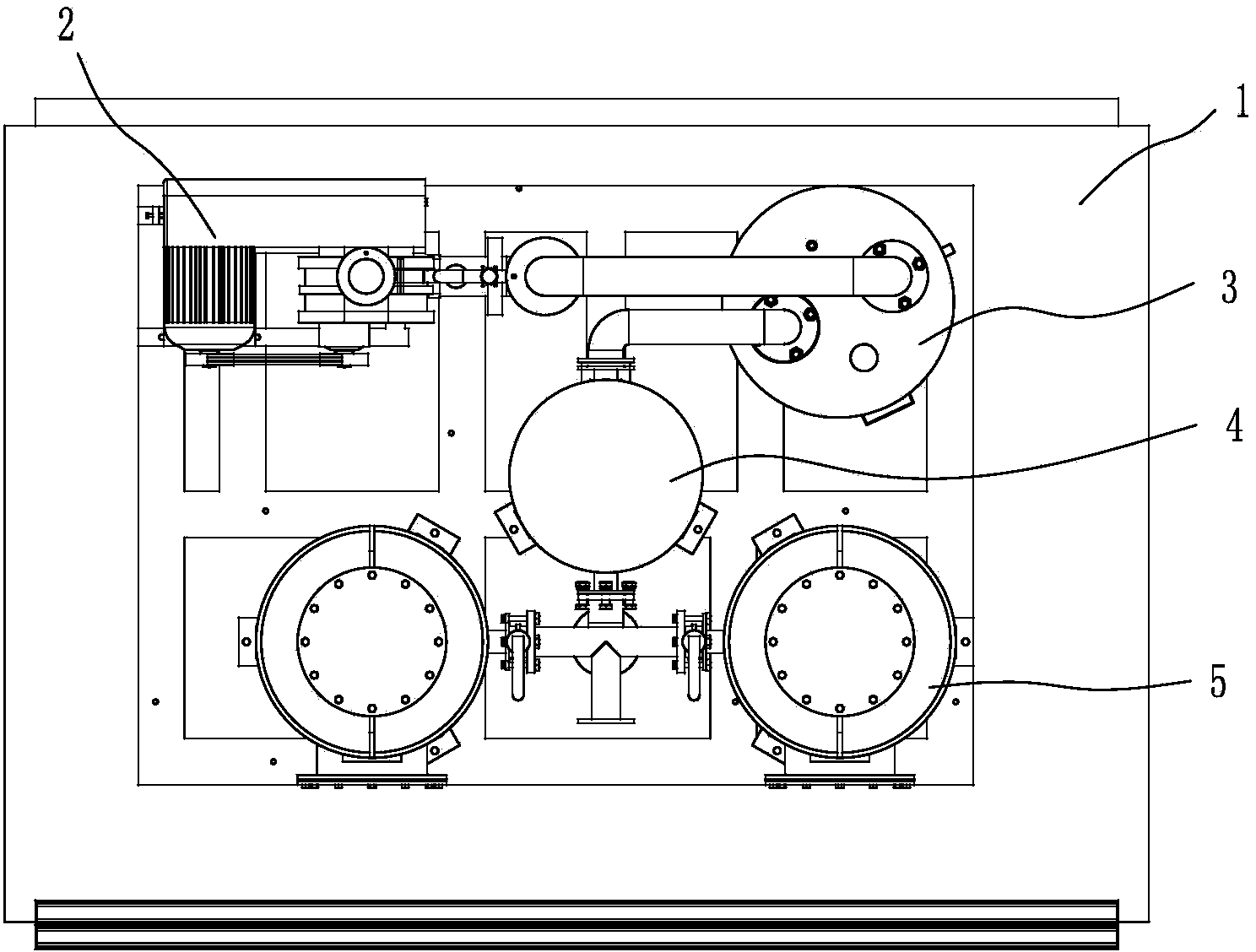

[0017] like figure 1 and figure 2 As shown, the integrated biogas treatment system includes a treatment box 1, and is installed in the treatment box:

[0018] The biogas booster fan 2 is connected with the gas storage tank;

[0019] The fire arresting device 3 is connected to the gas outlet end of the biogas booster fan 2;

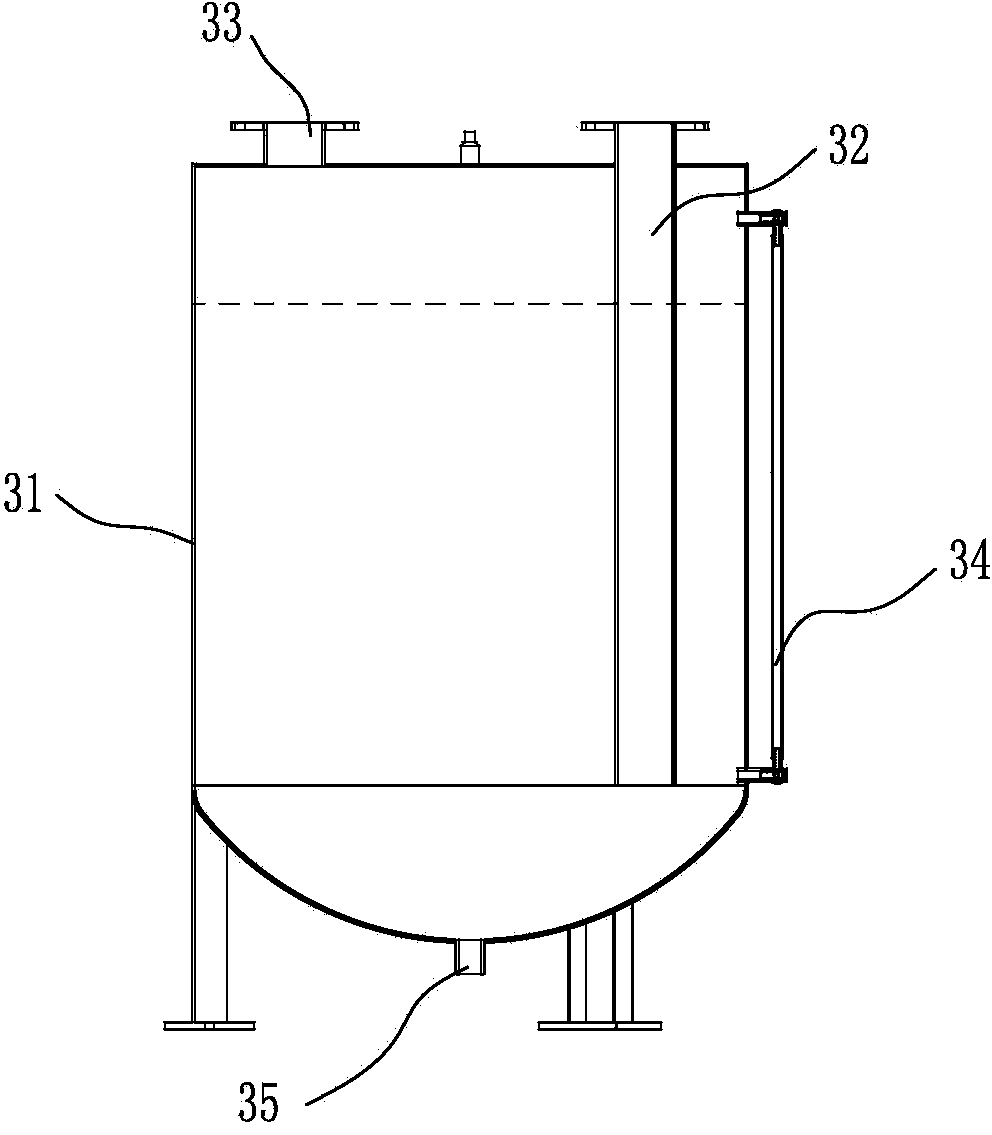

[0020] The water removal tank 4 is connected to the gas outlet of the fire arresting device 3;

[0021] The desulfurization device 5 is connected with the gas outlet of the water removal tank 4 .

[0022] The biogas booster blower 2 is a Roots blower. The biogas from the gas storage tank is pressurized by the Roots blower, which can improve the phenomenon of insufficient gas pressure, make the gas burn more fully, and have greater firepower. Reliable sealing, no leakage, safe and reliable. After configuring the automatic control system, it can achieve automatic switching within the set pressure range. When the gas source is insufficient, the booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com