Heating device of annular part and annular cavity of heating device

A technology of ring components and heating devices, which is applied in the maintenance of heating chambers, lighting and heating equipment, furnace components, etc., can solve the problems of increasing manufacturing costs, increasing the structural size of the main beam, and increasing the power of the fan drive motor, etc., to achieve The effect of reducing manufacturing costs, reducing heat energy waste, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

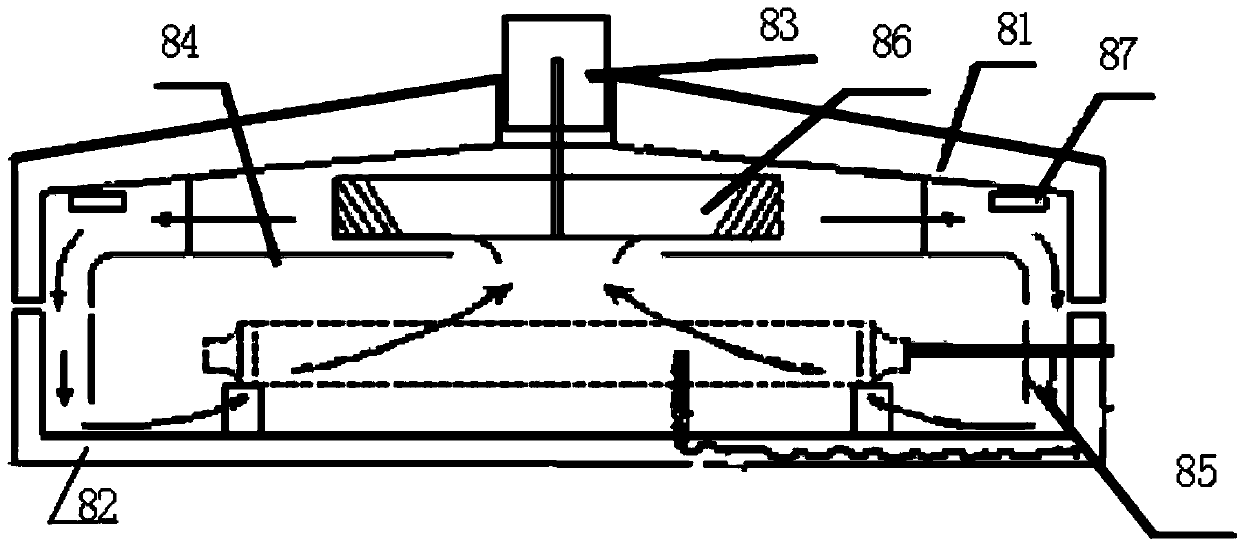

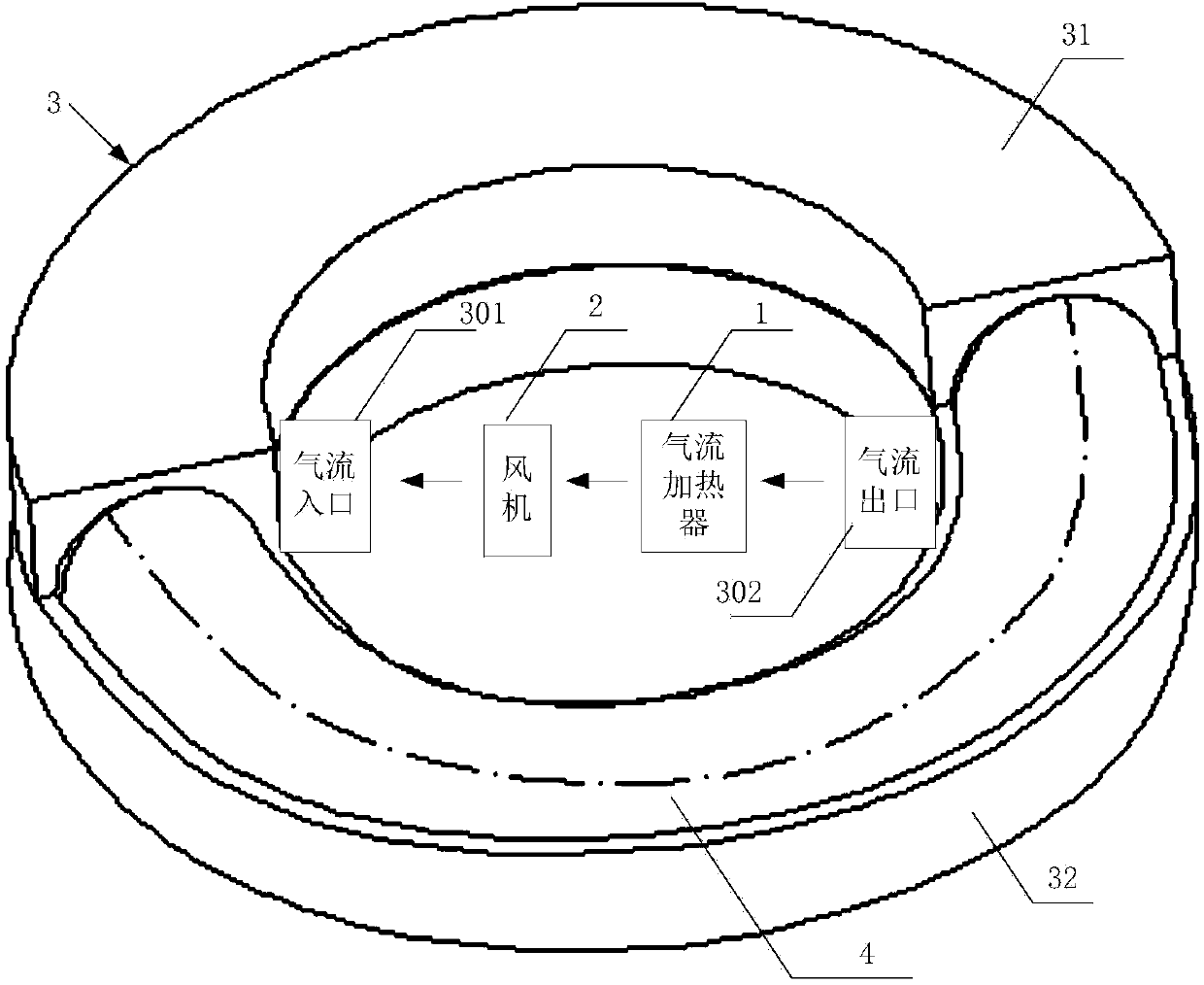

[0023] Such as figure 2 As shown, it is a structural schematic diagram of the heating device for the annular component in Embodiment 1 of the present invention. The heating device of the annular component of the present embodiment heats the annular component through the hot air flow, and it includes an airflow heater 1 and a fan 2, and also includes an annular cavity 3 for accommodating the annular component 4, and the outer wall of the annular cavity is provided with The airflow inlet 301 and the airflow outlet 302 , the airflow heater 1 heats the airflow, the fan 2 makes the airflow enter the airflow inlet 301 , and discharge from the airflow outlet 302 after passing through the airflow path in the annular cavity. In order to show the internal structure of the annular cavity 3, in figure 2 In , half of the upper annular cavity 31 is removed to show the state after the annular component 4 is put into the annular cavity 3 .

[0024] The structure of the heating device of t...

Embodiment 2

[0038] In addition to the improvement on the overall structure, the embodiment of the present invention further improves the interior of the annular cavity.

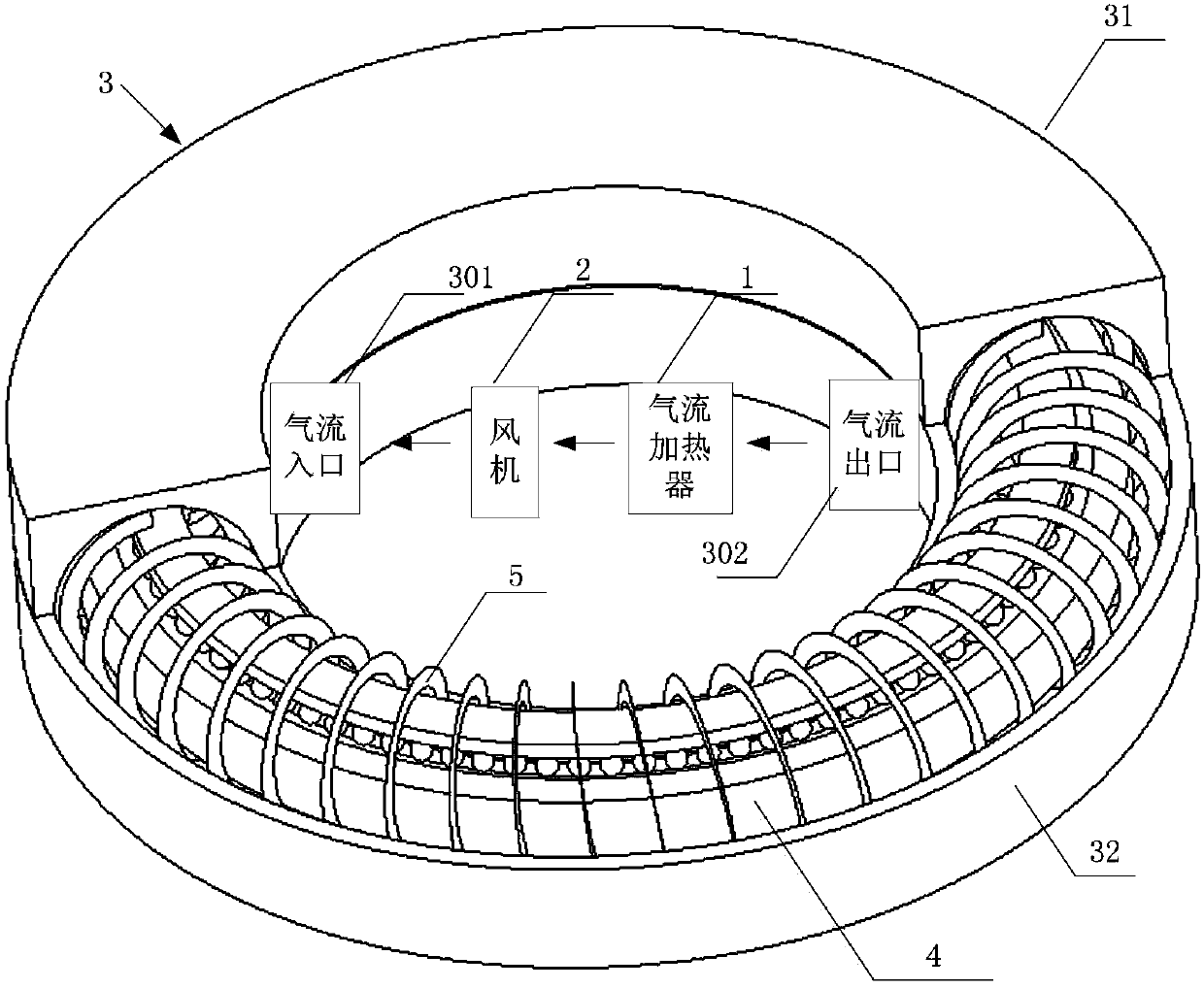

[0039] image 3 It is a structural schematic diagram of a heating device for an annular component in Embodiment 2 of the present invention, as image 3 As shown, on the basis of the first embodiment, a guiding body is provided in the annular cavity 3, and the guiding body makes the air flow move evenly along the surface of the annular component. By arranging the guide body in the annular cavity 3, the flow mode of the air flow is controlled, thereby making the annular component heated evenly and improving the heating efficiency.

[0040] Preferably, the guide body is a guide spiral fin 5, through which the guide spiral fin 5 makes the hot air flow trajectory into the annular cavity become around the ring part 4 (such as image 3 The solenoid-like movement of the large bearing part shown in ) heats the ring part 4 more ...

Embodiment 3

[0046] On the basis of the second embodiment, the present invention further improves the structure of the guide spiral fins 5, which will be described in detail below.

[0047] During the movement of the hot air from the air inlet 301 to the air outlet 302, the temperature will drop, and the heat exchange between the heated annular component 4 and the hot air will gradually decrease, resulting in uneven heating.

[0048] According to Newton's law of cooling,

[0049] Formula 1)

[0050] In this example, Be the heat exchange heat of hot air flow and the surface of ring part 4, A is the effective heat release area when hot air flow contacts with the surface of ring part 4, T is the temperature of hot air flow, Tw is the temperature of the surface of ring part 4, h is Surface heat transfer coefficient (also known as surface heat transfer rate). It can be seen from the formula (1) that A is a relatively fixed value, therefore, the heat exchange rate between the hot air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com