Mounting mechanism of continuous wall grab bucket

A technology for installing mechanisms and wall grabs, which is applied to earth movers/excavators, construction, etc., can solve problems such as low reliability and safety uncertainty, improve the overall structure and performance, improve safety, Effect of reduced pulling force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

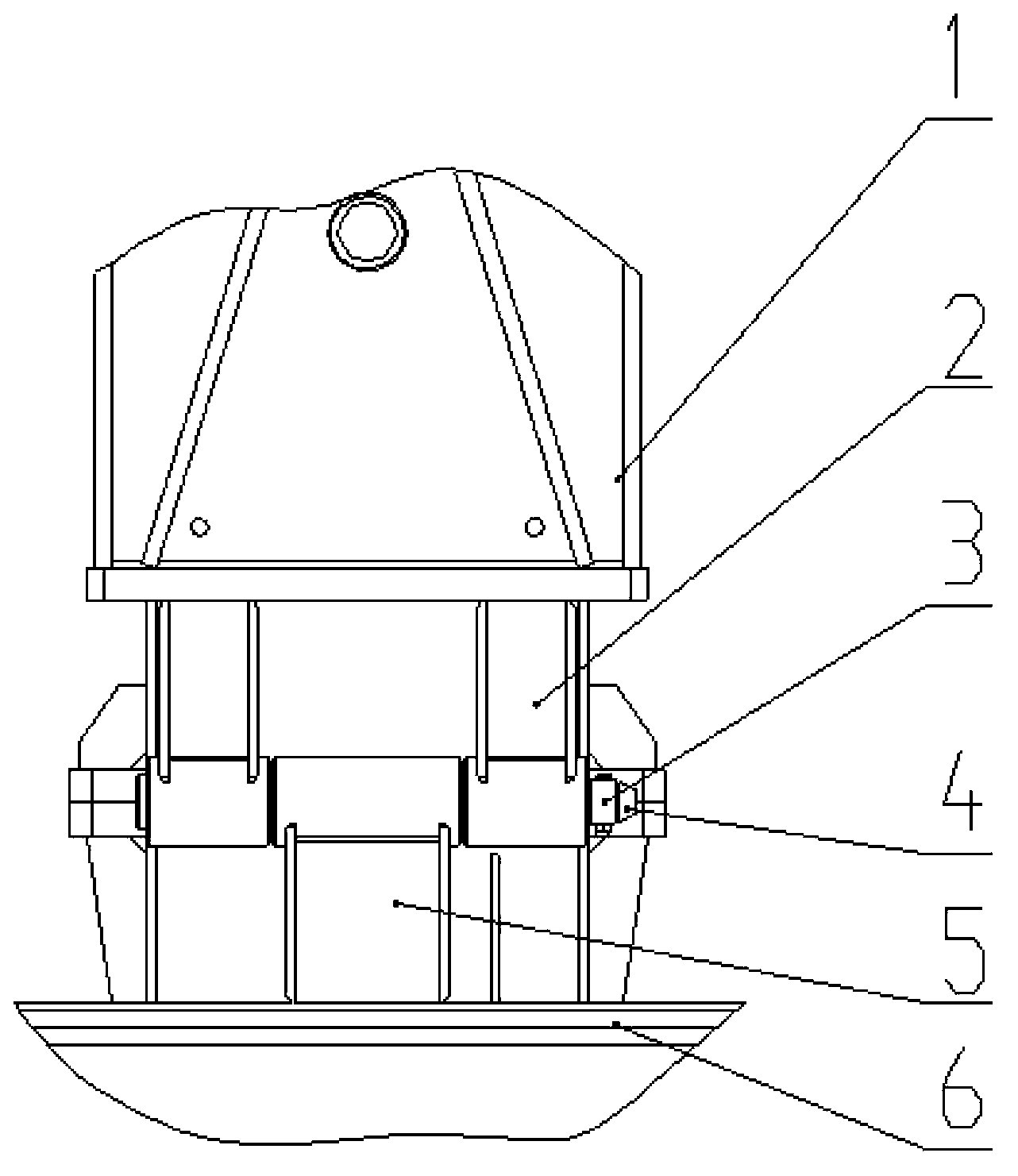

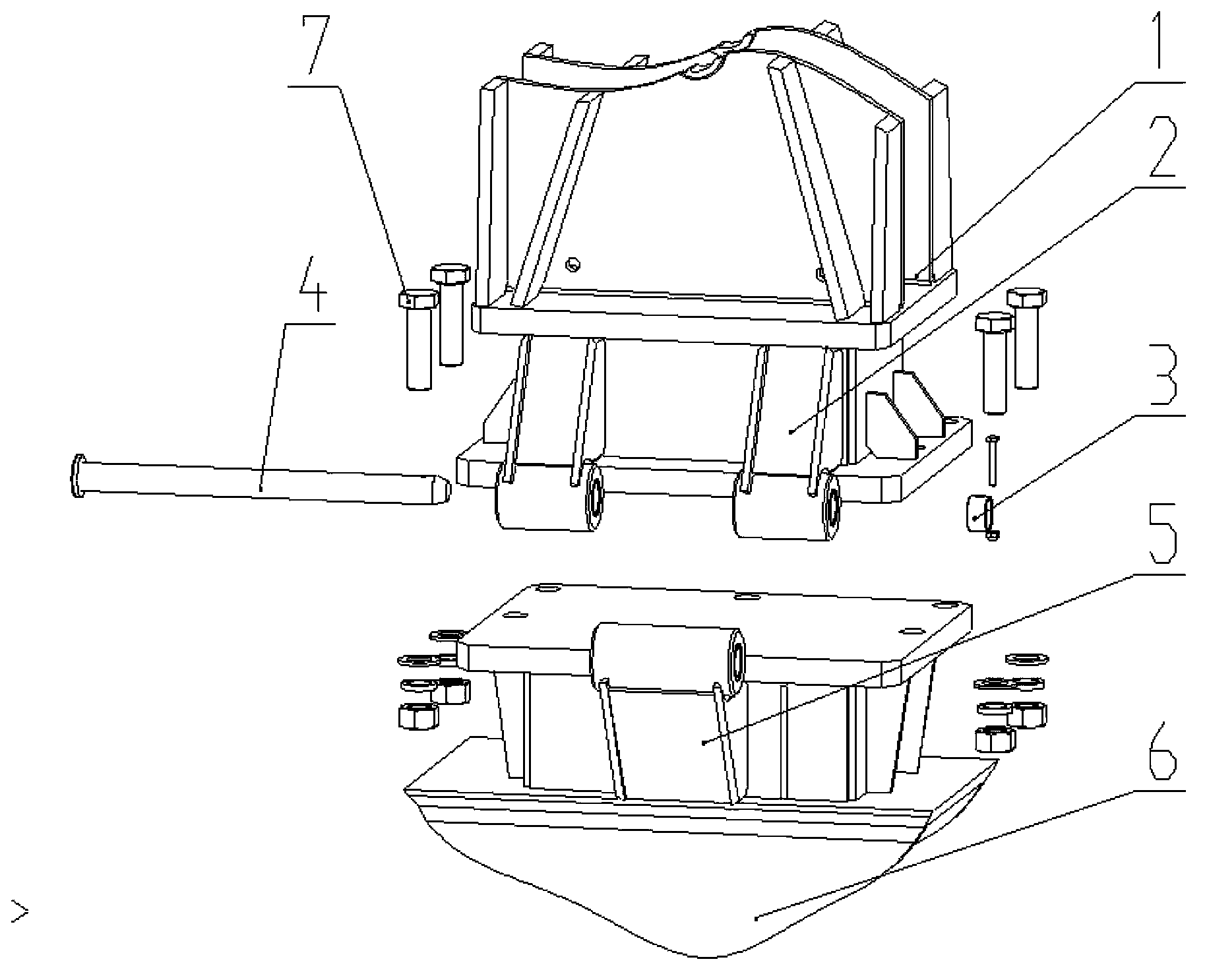

[0010] Such as figure 1 , figure 2 As shown, the installation mechanism of the diaphragm wall grab includes the lower section guide rod 1, the guide rod shaft sleeve 2 installed on the lower section guide rod 1, the grab body 6, the shaft sleeve 5 installed on the grab body, and the connecting pin 4. The pin positioning collar 3 and the connecting bolt 7 . The guide rod rotating shaft sleeve 2 is welded on the lower section guide rod 1. The rotating shaft sleeve 5 is welded on the grab body.

[0011] When assembling the grab, the grab body 6 and the lower section guide rod 1 are hinged with the connecting pin 4 through the guide rod shaft sleeve 2 on the lower section guide rod 1 and the shaft sleeve on the grab body 6, so that the When raising the mast, since the grab body 6 and the lower section guide rod 1 are hinged, the mast will get rid of the gravity of the grab when it is lifted, and the mast will be lifted to the final state first, and the guide rod is in the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com