Parallel-connection jacking pressure non-negative pressure water supply device

A water supply equipment, parallel technology, applied in the water supply main pipeline, water supply pipeline system, water supply pool configuration and other directions, can solve the problems of water pollution, bringing in other bacteria, and bubbles in the water in the tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

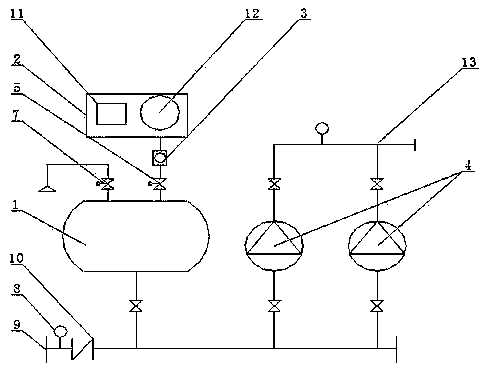

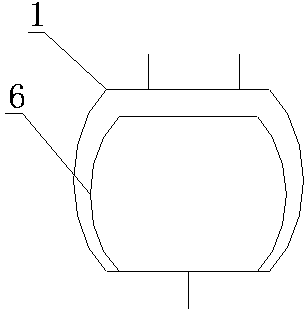

[0009] Such as figure 1 The shown parallel top pressure stacked water supply equipment consists of: water storage tank 1, inflation device 2, pressure reducer 3, water pump 4, controller 5, exhaust device 7, tap water volume detection device 8 and control cabinet (not shown in the figure) standard) and connecting pipes. The water pump 4 and the water storage tank 1 are connected in parallel with the tap water inlet 9 through a pipeline, and a one-way valve 10 is installed at the tap water inlet 9, and the tap water volume detection device 8 is installed between the tap water inlet 9 and the one-way valve 10. The device 7 is connected to the water storage tank 1, the inflator 2 is provided with an air compressor 11 and an air storage tank 12, the air storage tank 12 is connected with the water storage tank 1 after passing through the pressure reducing valve 3 and the controller 5, the outlet of the water pump 4 and the The water outlet main pipe 13 is connected, and the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com