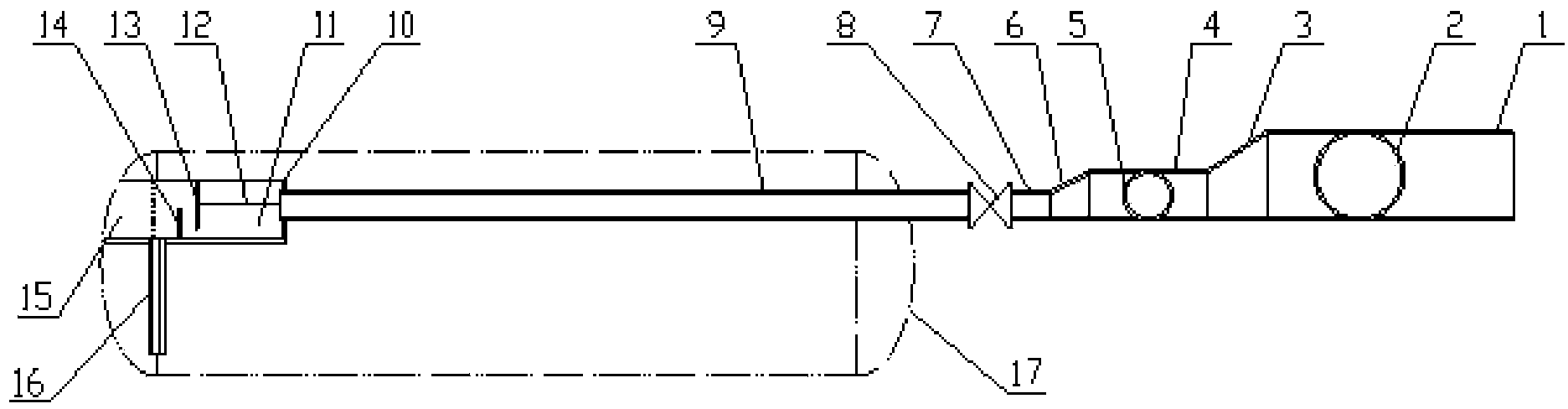

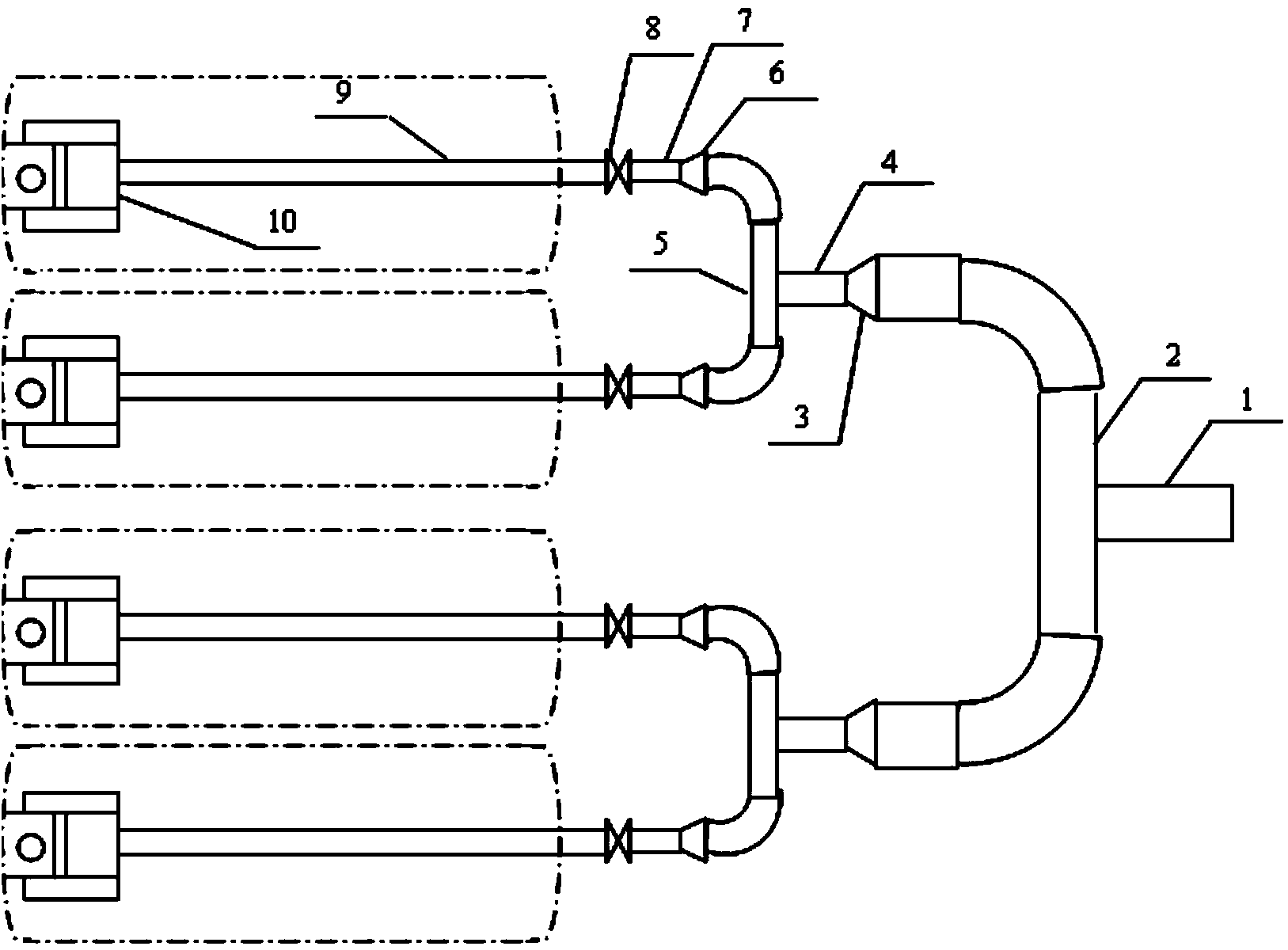

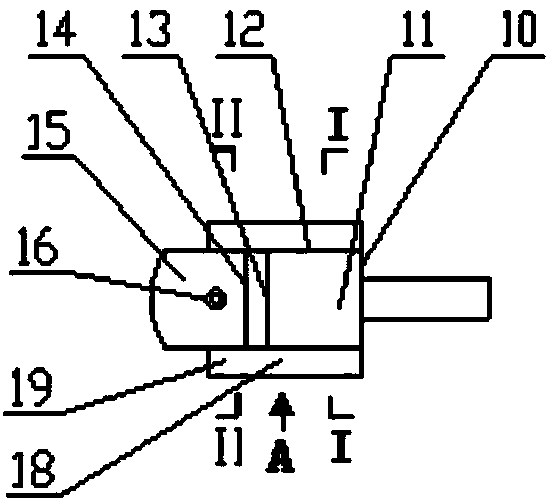

Layered and balanced medium entering system and method of parallel multiphase separation equipment

A multi-phase separation and three-phase separation technology, which is applied in the field of oil and water separation of gas and oil field surface engineering production fluid, can solve the problems of bias flow and low processing capacity of each equipment, and achieve flow balance and oil-water separation interface stability , Improve the effect of the overall separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -1

[0075] Example-1: Through technological transformation, a set of 2 sets of Ф4×24m three-phase separator groups operating in parallel is established to enter the system layered and balanced, and the inlet medium is the liquid phase water content from the oil well group with a water content of 95.3% The oil-gas-water mixture of extra-high water content and high condensation crude oil. After the system was put into use, the oil-water interface of the two equipment tended to be stable and consistent, and the overall oil-water separation treatment capacity increased by 20% compared with the conventional sequential entry process before the transformation.

Embodiment -2

[0076] Example-2: In the production capacity construction project of overseas oilfields, a new set of 4 sets of Ф3.4×20m three-phase separators operating in parallel are layered and balanced into the system, and the inlet medium is the liquid phase water from the oil well group Low-point crude oil-gas-water mixture with a rate of 50%. After the system was put into use, the oil-water interface of the four equipment tended to be stable and consistent, and the overall oil-water separation treatment capacity increased by 15% compared with the conventional sequential entry process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com