Precise adjustment system for vacuum degree of giant vacuum chamber

A technology of regulating system and vacuum chamber, applied in the direction of machine/engine, etc., can solve the problems of lack of automation, small laboratory volume, inability to meet the requirements of extra-large vacuum system, etc., and achieve the effect of stable regulation and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

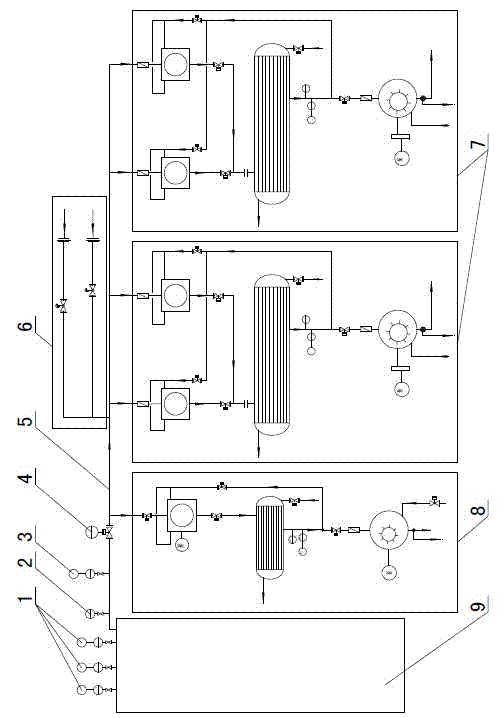

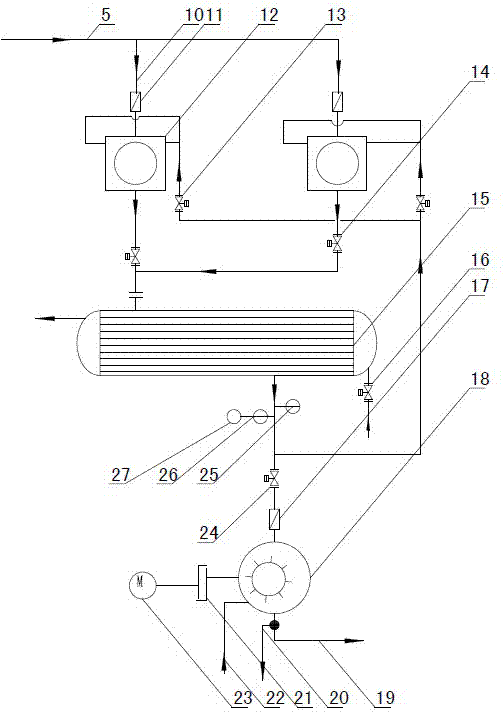

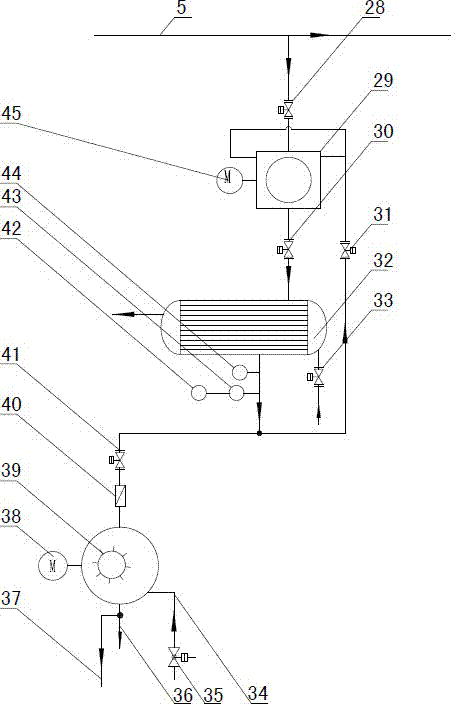

[0024] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0025] Such as figure 1 Shown, the volume of the vacuum chamber 9 of the precise adjustment system of the vacuum degree of the giant vacuum chamber of the present invention can reach 12000m 3 ~15000m 3 A plurality of vacuum chamber pressure transmitters 1 are installed on the vacuum chamber 9, and the main vacuum pipeline 5 is drawn out from the vacuum chamber 9 side. In the main vacuum pipeline 5, a main pipeline pressure gauge 2, a main pipeline pressure transmitter 3 and a main pipeline switch valve 4 are connected in series in sequence, and then a group of maintaining vacuum pumping units 8 and two sets of main vacuum pumping units 7 are connected in parallel at the same time. One or more sets of vacuum pumping units 7 can be arranged as required, and an air supply unit 6 is connected in parallel betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com