High precision brakes for variable stroke cylinders

A brake, high-precision technology, applied in the direction of brake types, drum brakes, fluid pressure actuators, etc., can solve problems such as difficult implementation, and achieve the effects of avoiding scratching the airbag, uniform braking force distribution, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

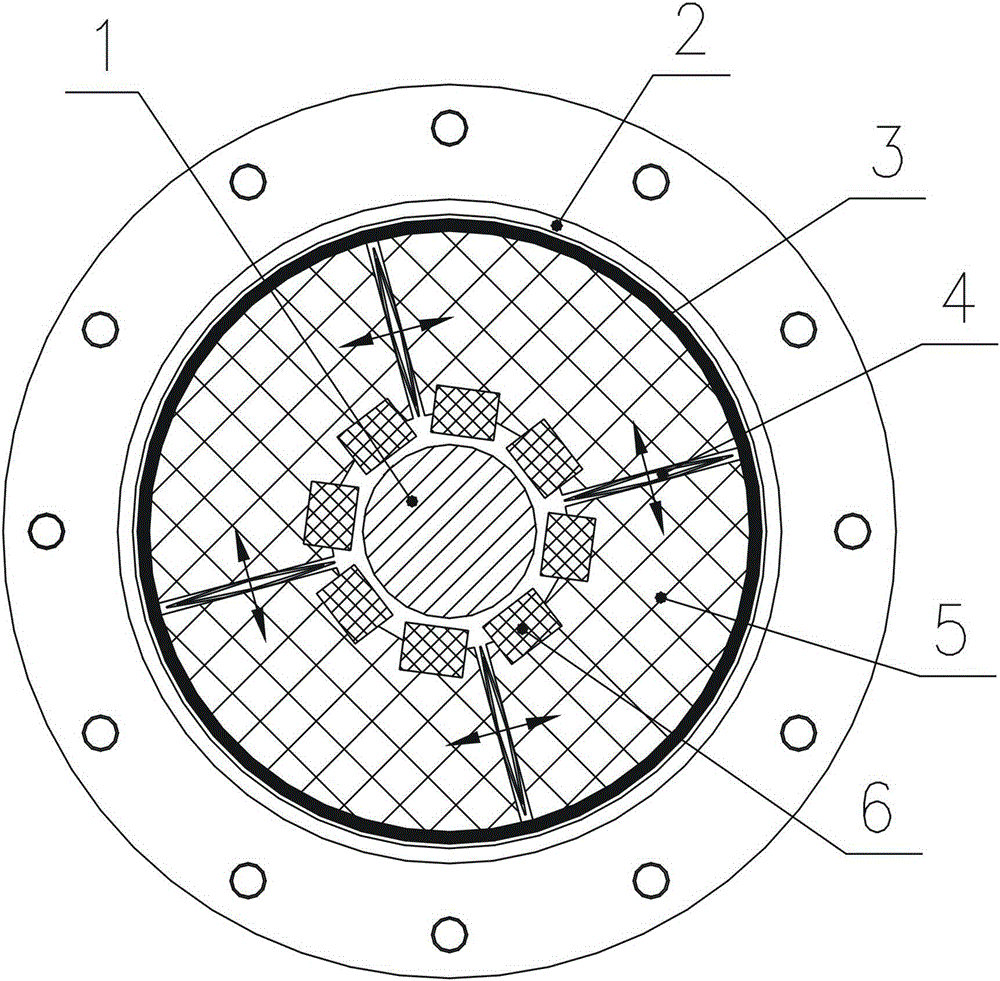

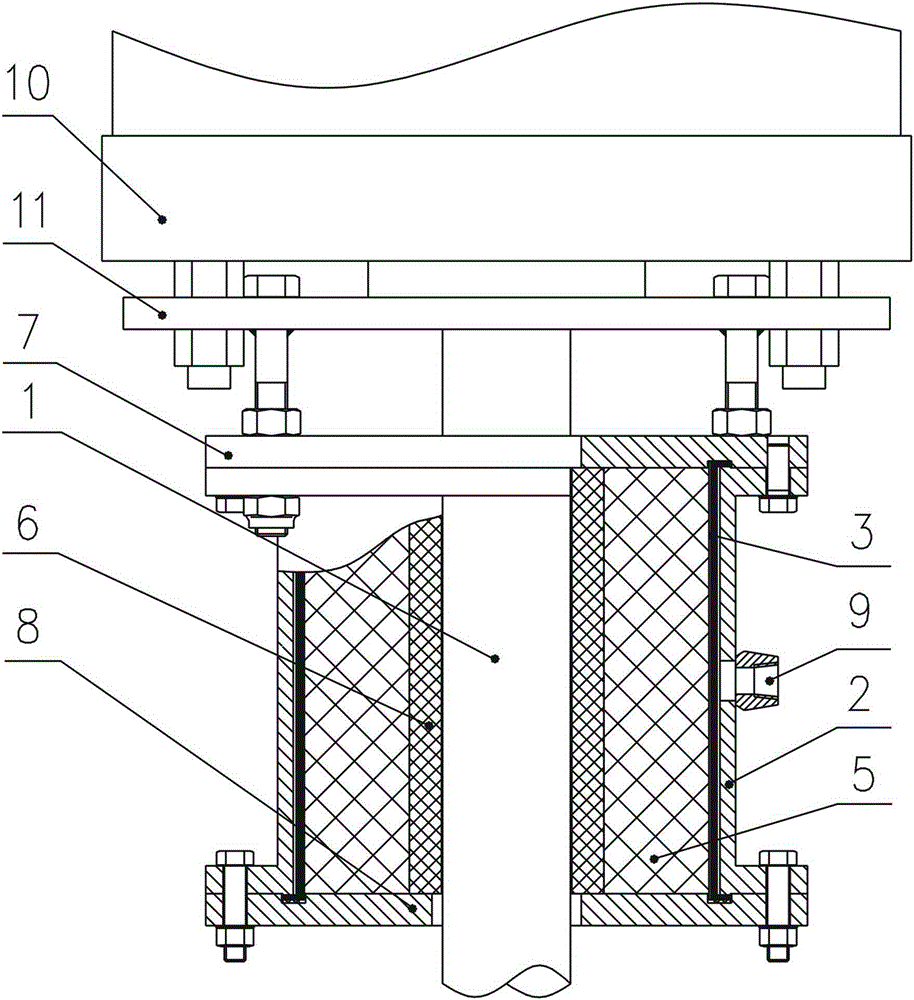

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described (as figure 1 with 2 ).

[0027] A high-precision brake for a variable stroke cylinder, the brake is mainly composed of a brake cylinder block 2, a cylindrical air bag 3 and a plurality of transmission blocks 5 with fan-shaped cross-sections; the air bag 3 is located in the Inside the cylinder body 2 of the moving cylinder, and close to its inner wall; the multiple transmission blocks 5 are arranged rotationally symmetrically inside the airbag 3 with the center of the airbag 3 as a fixed point (multiple transmission blocks 5 are distributed around the piston rod 1), the The outer side of each transmission block 5 is close to the air bag 3, and the inner side of the transmission block 5 is provided with a brake pad 6 (the side close to the piston rod 1), and a compressed airbag is provided between every two adjacent transmission blocks 5. Spring 3; the brake cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com