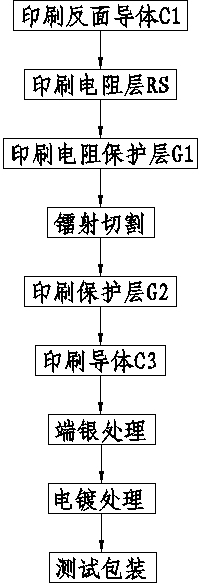

Reverse-side printing process for resistor protruding electrode

A technology of reverse printing and resistors, applied in resistors, resistor manufacturing, circuits, etc., can solve the problems of low TCR level of products, bruised electrodes at the resistor terminals, and easy dispersion of the initial value of the resistor, so as to avoid the function failure of the original resistor, The effect of improving the TCR level and shortening the current stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

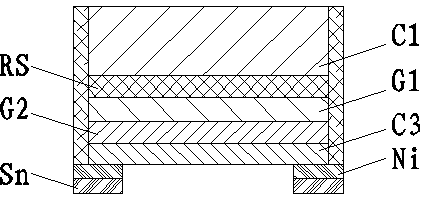

[0052] In this embodiment, the thickness of the reverse conductor C1 is 150 μm, and the ink printing temperature of the reverse conductor C1 is 850°C. The thickness of the resistance layer RS is 15 μm, the ink printing temperature of the resistance layer RS is 850° C., and the resistance value range of the resistance layer RS is ±35% of the required resistance value. The thickness of the resistance protection layer G1 was 15 μm, and the ink printing temperature of the resistance protection layer G1 was 600°C. The thickness of the protective layer G2 was 15 μm, and the ink printing temperature of the protective layer G2 was 190°C. The thickness of the conductor C3 is 150 μm, and the ink printing temperature of the conductor C3 is 230°C.

Embodiment 2

[0054] In this embodiment, the thickness of the reverse conductor C1 is 15 μm, and the ink printing temperature of the reverse conductor C1 is 800°C. The thickness of the resistance layer RS is 5 μm, the ink printing temperature of the resistance layer RS is 800° C., and the resistance value range of the resistance layer RS is ±35% of the required resistance value. The thickness of the resistance protection layer G1 was 5 μm, and the ink printing temperature of the resistance protection layer G1 was 550°C. The thickness of the protective layer G2 is 5, and the ink printing temperature of the protective layer G2 is 140°C. The thickness of the conductor C3 is 15 μm, and the ink printing temperature of the conductor C3 is 180°C.

Embodiment 3

[0056] In this embodiment, the thickness of the reverse conductor C1 is 300 μm, and the ink printing temperature of the reverse conductor C1 is 900°C. The thickness of the resistance layer RS is 25 μm, the ink printing temperature of the resistance layer RS is 900° C., and the resistance value range of the resistance layer RS is ±35% of the required resistance value. The thickness of the resistance protection layer G1 was 25 μm, and the ink printing temperature of the resistance protection layer G1 was 650°C. The thickness of the protective layer G2 was 25 μm, and the ink printing temperature of the protective layer G2 was 240°C. The thickness of the conductor C3 is 300 μm, and the ink printing temperature of the conductor C3 is 280°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com