A graphene-based mercury cadmium telluride composite film material and preparation method thereof

An alkenyl cadmium telluride and composite thin film technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of restricting the development of mercury cadmium telluride FPA devices, high quality requirements, and poor stability , to achieve the effect of easy processing, large area and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

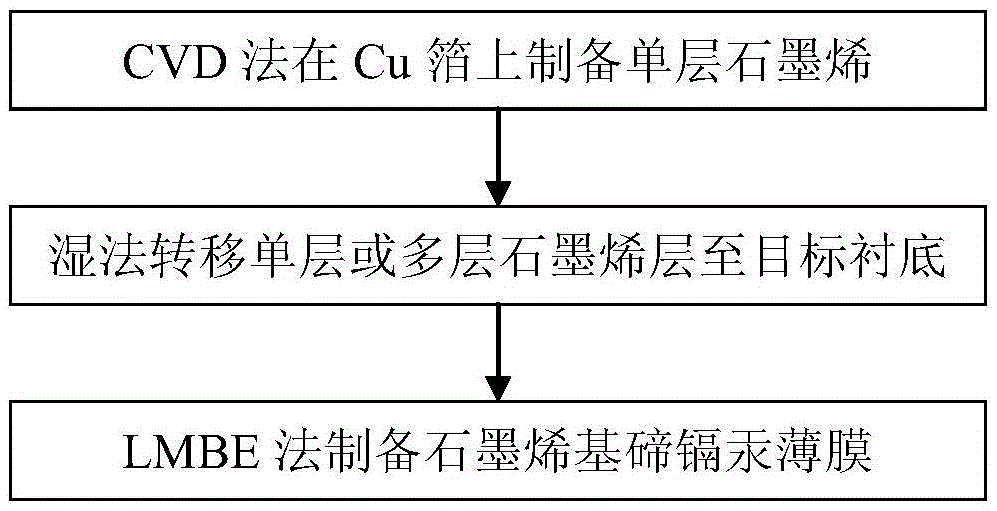

[0030] (1) Preparation of graphene

[0031] Put the copper foil into a vacuum chemical vapor deposition (CVD) system composed of a high-temperature tube furnace and a compound molecular pump, pump the system to below 10Pa, and start heating up. When the temperature rises to 300°C, H is introduced into the 2 (Flow rate 50sccm), continue to heat up to 1050°C, keep the temperature for 20 minutes and then pass CH 4 (Flow 50sccm), after 50 minutes of ventilation, turn off CH 4 , after keeping the constant temperature for 15 minutes, turn off the H 2 , followed by rapid cooling to obtain single-layer graphene.

[0032] (2) Using wet transfer technology to transfer single-layer graphene to amorphous glass substrate

[0033] The specific operation is: cut the copper foil deposited with graphene into a 15mm*15mm square, and evenly spin-coat PMMA on one side, then place it on a heating plate at 130°C for 30 minutes, and then put 1mol / l FeCl 3 Soak in the solution at room temperatu...

Embodiment 2

[0038] (1) Put the copper foil into a vacuum chemical vapor deposition (CVD) system composed of a high-temperature tube furnace and a compound molecular pump, pump the system airtightly below 10Pa, and start heating up. When the temperature rises to 300°C, H is introduced into the 2 (Flow rate 50sccm), continue to heat up to 1050°C, keep the temperature for 20 minutes and then pass CH 4 (Flow 50sccm), after 50 minutes of ventilation, turn off CH 4 , after keeping the constant temperature for 15 minutes, turn off the H 2 , followed by rapid cooling to obtain single-layer graphene.

[0039](2) Using wet transfer technology to transfer multi-layer graphene to amorphous glass substrate

[0040] The specific operation is: cut the copper foil deposited with graphene into multiple 15mm*15mm squares, and evenly spin-coat PMMA on one side, then place it on a heating plate at 130°C for 30 minutes, and then put 1mol / l FeCl 3 Soak in the solution at room temperature until the graphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com