Permanent magnet motor system with shared bus structure and open winding and control method for suppressing zero-sequence current

A permanent magnet motor, zero-sequence current technology, applied in motor generator control, electronic commutation motor control, control system, etc., can solve the problem of increasing system hardware cost and complexity, zero-sequence current flow, third harmonic To suppress and other issues, to achieve the effect of simple system complexity, suppression of zero-sequence current, and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

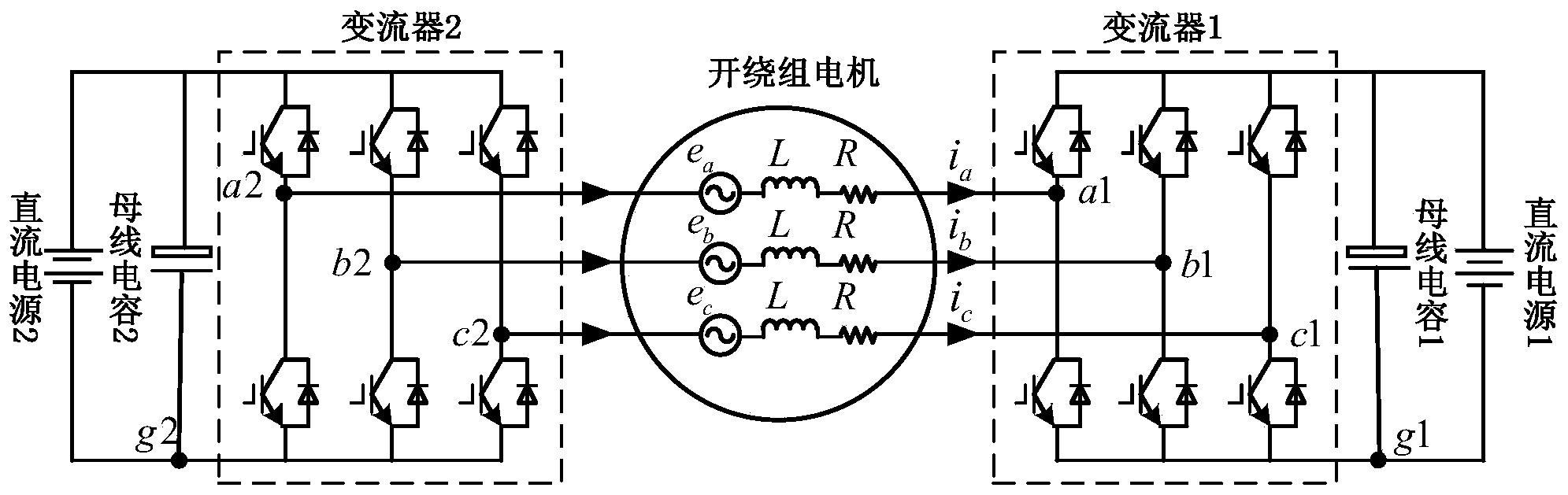

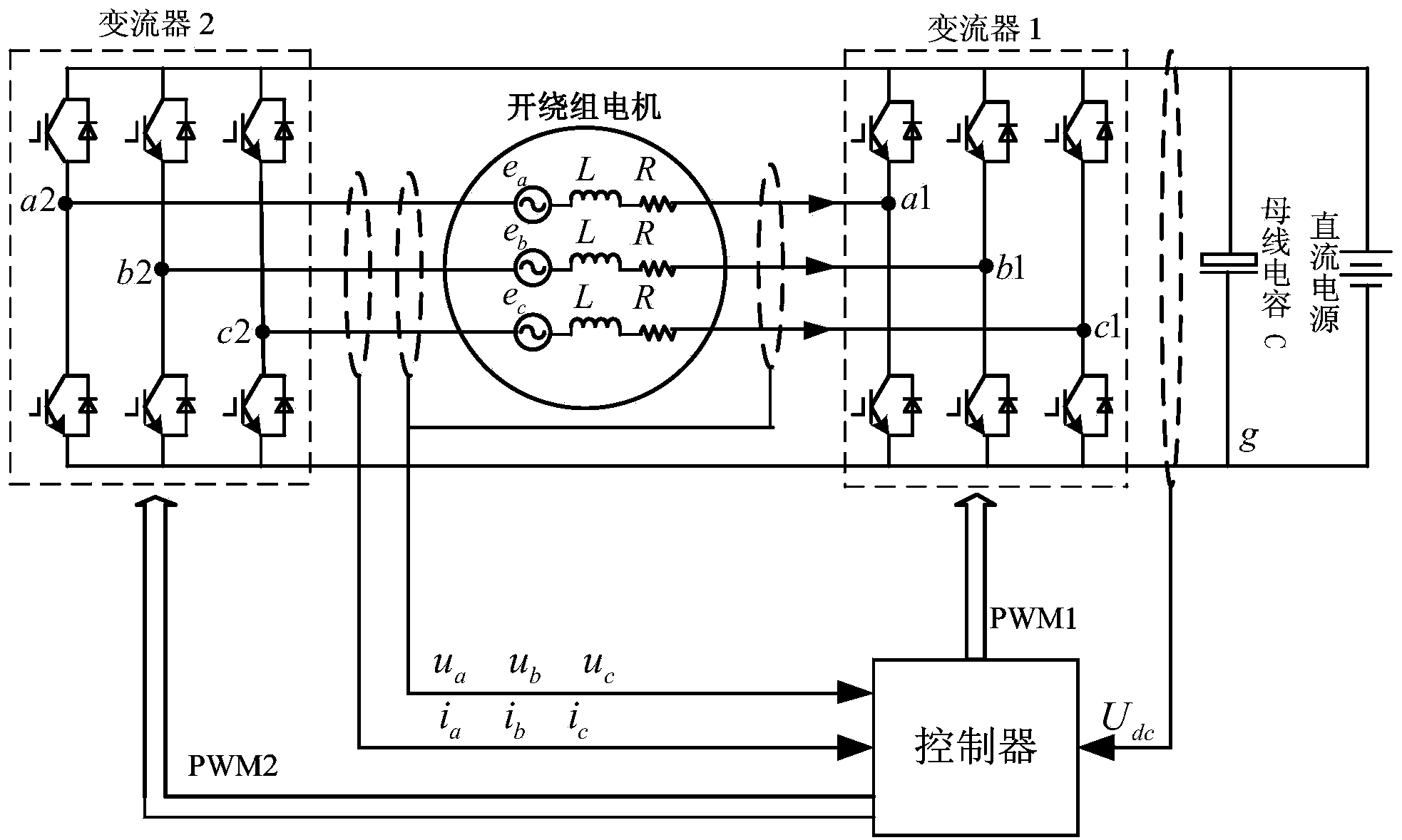

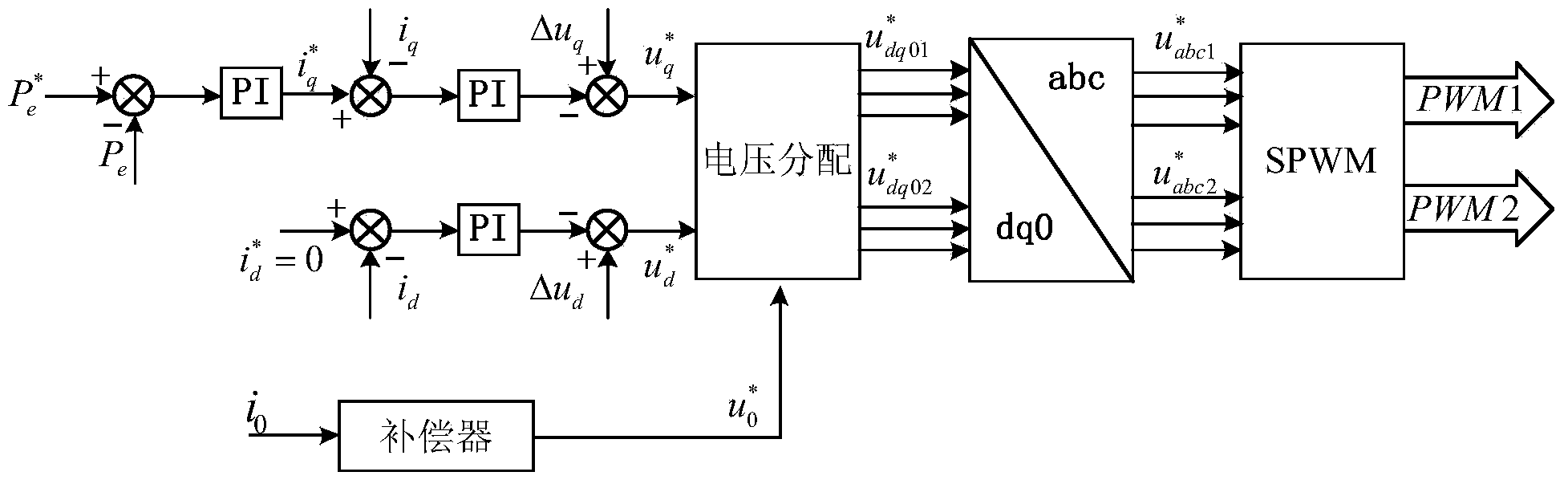

[0045] Such as figure 2 As shown, an open-winding permanent magnet motor system based on a common DC bus includes: a permanent magnet motor, two converters J1~J2, a DC power supply S and a controller; the permanent magnet motor has three phase winding, and is an open winding structure; converters J1 and J2 use three-phase full-bridge rectifiers, and the DC sides of converters J1 and J2 share the same DC power supply, and there is a bus capacitor C on the DC power supply, and each bridge arm It consists of at least one power electronic switching device in series. In this embodiment, the switching device adopts IGBT; one end of any phase winding of the permanent magnet motor is connected to the center contact of the upper and lower bridge arms of the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com