Method and device for detecting a deterioration in the state of an insulation in an operating electric machine

A technology of insulation state and deterioration, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as failure to find insulation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

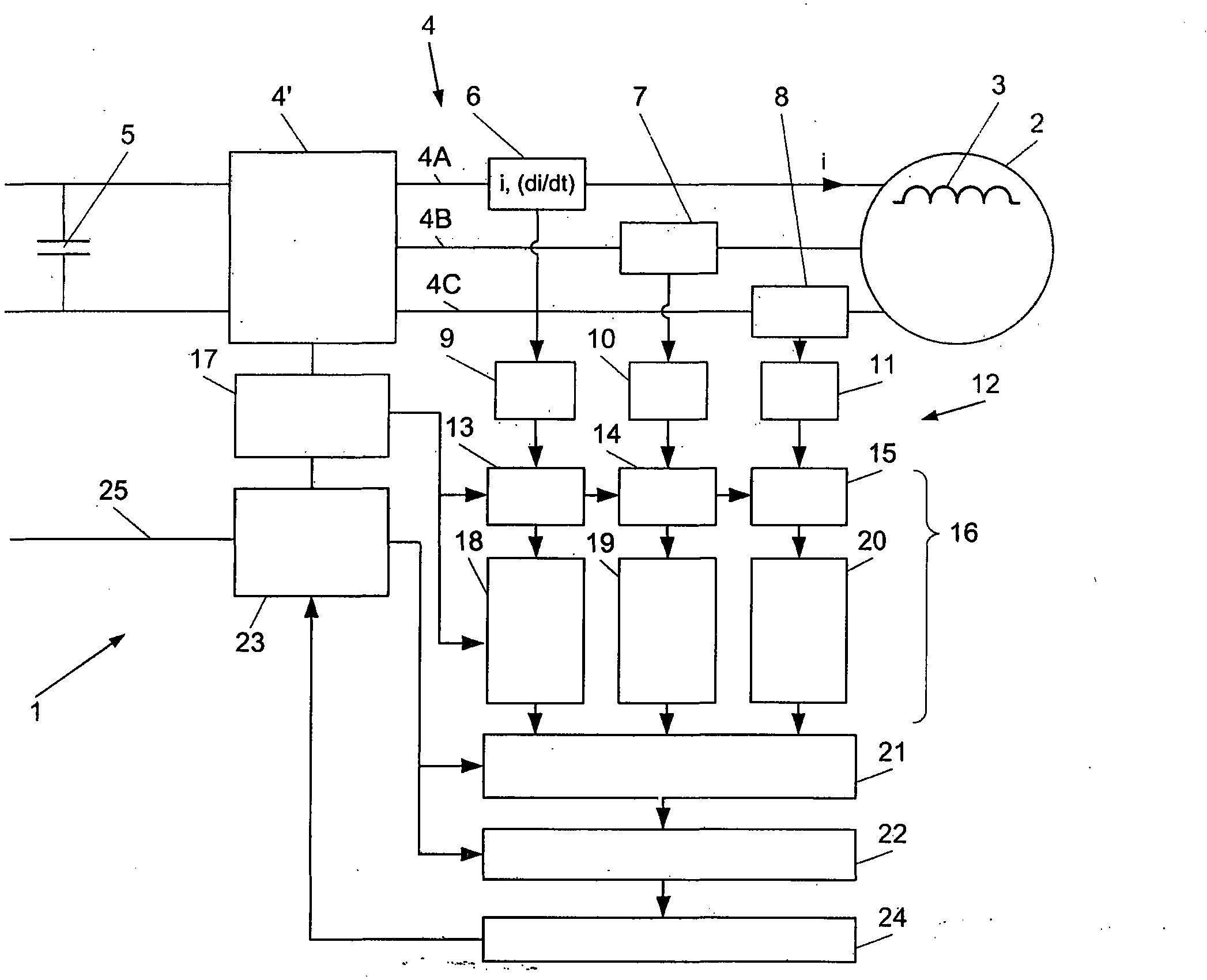

[0044] figure 1 A schematic diagram of a preferred embodiment of the device according to the invention for the on-line detection of deterioration of the insulation state in an electrical machine is shown, which preferred embodiment is particularly suitable for carrying out the method of the invention.

[0045] figure 1 The device 1 shown in is used for on-line monitoring of a motor (induction motor) 2, which can be a single-phase motor or a multi-phase motor, wherein, although in figure 1 Only a single winding 3 is shown schematically for a motor 2 in figure 1 , take for example three phases. The electric machine 2 has a power supply circuit or supply circuit 4 assigned to the electric machine 2 , which has three corresponding current supply lines 4A, 4B and 4C. The power supply circuit 4 also includes an inverter 4', which provides a corresponding voltage signal for the motor 2. In addition, the figure shows a DC terminal capacitance 5 associated with the inverter 4'.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com