Clothes hanger with antiskid teeth

A technology for anti-slip teeth and hangers, which is applied to hangers, clothing, applications, etc., can solve the problems of non-degradable plastic or rubber strips, complicated production processes, and high cost of hangers, and achieves the advantages of saving manpower and material resources, simple production processes, and shortened production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

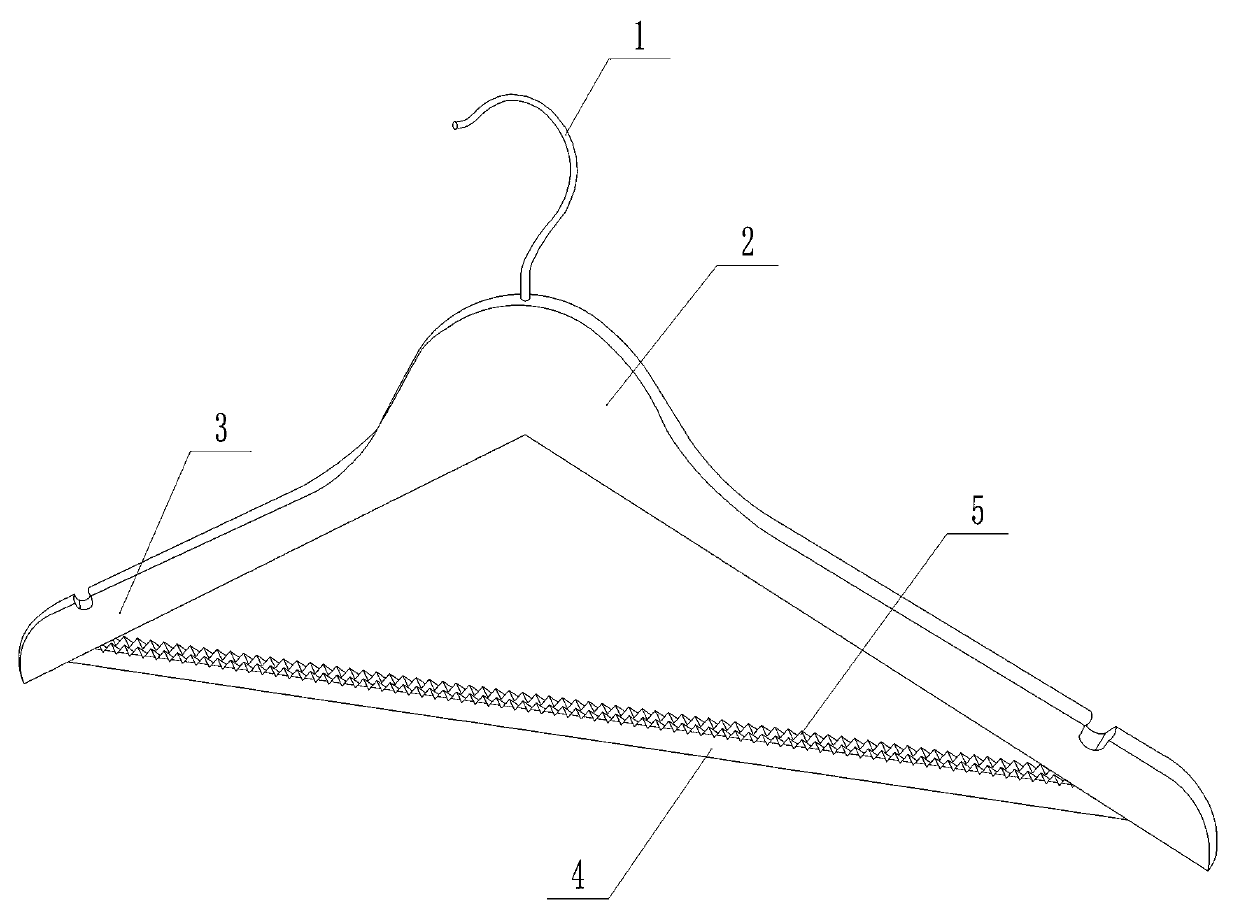

[0013] refer to figure 1 , a clothes hanger with anti-slip teeth, comprising a hook 1, a main body 2 with an arm support 3 extending obliquely to the left and right ends, and a lower cross bar 4 connecting the arm supports 3 at both ends, the lower cross bar 4 The upper end face is anti-skid rack 5, and anti-skid rack 5 is made of timber or bamboo.

[0014] This kind of wooden clothes hanger can directly make the upper end surface of the lower cross bar 4 into anti-skid teeth, and also can fit the bamboo anti-skid teeth with the upper end surface of the wooden lower cross bar 4, or directly use bamboo to make the lower cross bar 4 , the upper end surface of the lower cross bar 4 made of bamboo is made into anti-slip teeth, which further reduces the production cost, saves a lot of manpower and material resources, and does not need special treatment after scrapping, and will not pollute the environment.

[0015] There are two anti-skid racks 5, which can have better anti-skid e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap